The Remote Control Heavy Load Battery Operated Railway Transfer Vehicle is a specialized rail-guided transport solution designed for moving heavy materials within industrial facilities.

Equipped with a powerful rechargeable battery system and wireless remote control, this transfer vehicle provides safe, efficient, and flexible movement of bulky loads such as:

Steel coils

Mold assemblies

Machinery components

Large raw materials

Finished products and heavy equipment

It is ideal for factories, warehouses, assembly lines, shipyards, and steel plants, offering a reliable alternative to forklifts and overhead cranes. By eliminating manual handling risks, this equipment helps reduce labor costs, increase productivity, and improve workplace safety.

Key Features

Battery Powered & Eco-Friendly

Self-contained battery system, no external power cables required.

Operates with zero emissions and low noise, ideal for indoor use.

Single charge provides 6-8 hours of continuous operation.

Supports fast charging and quick battery replacement to minimize downtime.

Heavy-Duty Load Handling

Built for extremely heavy loads, available from 5 tons up to 200 tons or more.

Strong welded steel frame ensures high durability and deformation resistance.

Suitable for handling bulky, irregularly shaped, or fragile items.

Remote Control Operation

Wireless remote control system allows operators to:

Control movement from a safe distance.

Adjust speed and direction precisely.

Perform emergency stops immediately when needed.

Reduces operator fatigue and minimizes collision risks in congested work areas.

Optional dual control mode: remote control + onboard pendant for versatility.

Smooth & Stable Rail Movement

Designed to run on pre-installed steel rails, ensuring:

Accurate positioning

Smooth operation

Efficient point-to-point transfer

No interference with pedestrian walkways or other mobile equipment.

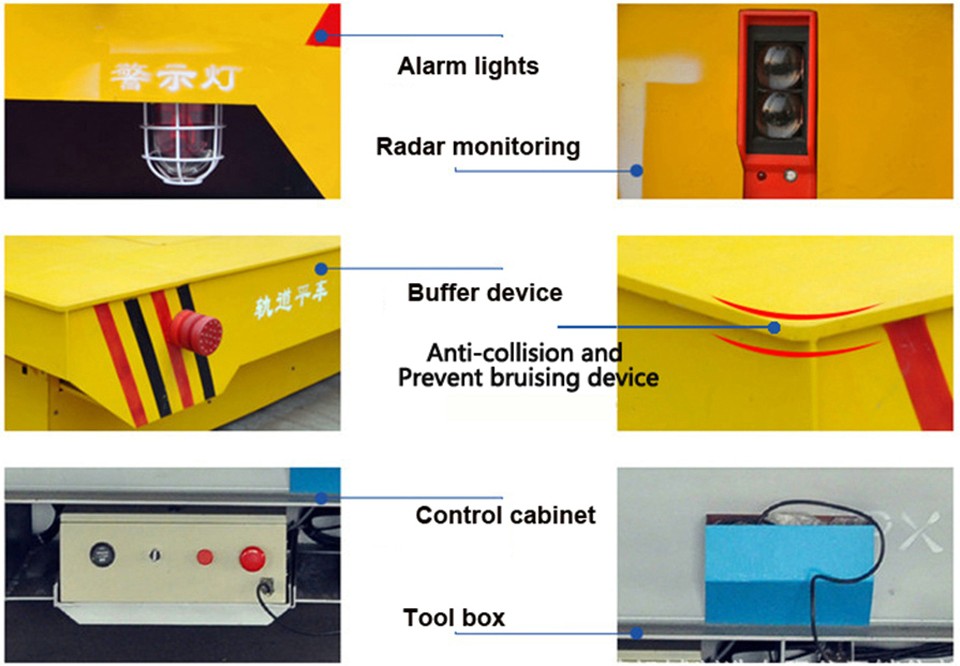

Safety-Oriented Design

Equipped with multiple safety systems to ensure reliable operation:

Emergency stop buttons

Audible and visual alarms

Limit switches for end-of-track protection

Soft start and soft stop control to prevent cargo damage

Optional laser sensors and infrared collision prevention system

Flexible Customization

Platform configurations: flat deck, V-frame for cylindrical goods, guard rails, or roller conveyors.

Control options: manual pendant, remote control, or full PLC automation.

Additional functions: hydraulic lifting table, weighing system, automated docking, or integration with smart warehouse systems.

Typical Applications

| Industry | Application |

|---|---|

| Steel Plants | Steel coils, billets, slabs, and heavy castings |

| Manufacturing | Transport of large components and raw materials |

| Automotive | Molds, chassis, and assembly line components |

| Shipbuilding | Heavy ship parts, engines, and modules |

| Warehousing | Bulk material transfer between storage and production |

| Mining | Handlingheavyore,miningtools,andequipment |

Technical Specifications

Load Capacity: Configurable from 5 tons to 200 tons (custom capacities available).

Power Source: Industrial battery pack, lead-acid or lithium-ion optional.

Battery Life: Continuous operation for 6-8 hours per charge.

Charging Options: Standard charger or fast-charging system.

Travel Speed: Adjustable between 0–20 meters per minute.

Control Method: Wireless remote control, manual pendant, or PLC automation.

Track Type: Standard industrial rails, customizable gauge from P18 to P50.

Safety Systems: Emergency stop, alarms, limit switches, optional laser or infrared sensors.

Operating Environment: -20°C to +50°C, with optional dust-proof or explosion-proof design.

Platform Options: Flatbed, V-frame, roller conveyor, hydraulic lifting deck.

Advantages

| Advantage | Description |

|---|---|

| Safe Operation | Remote control eliminates direct operator exposure to hazards. |

| High Load Capacity | Capable of transporting extremely heavy and oversized materials. |

| Eco-Friendly | Zero-emission battery-powered system for clean factory environments. |

| Cost-Efficient | Reduces labor costs and minimizes operational downtime. |

| Versatile Design | Customizable for different industries and material types. |

| Smart Integration | Compatiblewithautomatedproductionandwarehousesystems. |

Customization Options

| Category | Available Options |

|---|---|

| Power System | Lead-acid battery / Lithium-ion battery |

| Platform Design | Flat deck / V-frame / Guard rails / Roller conveyor / Hydraulic lift |

| Control System | Remote control / Manual pendant / PLC automation |

| Safety Features | Laser sensors / Infrared sensors / Automatic collision prevention |

| Operation Mode | Manual/Semi-automatic/Fullyautomated |

Why Choose Remote Control Battery Transfer Vehicles?

Improved Safety: Operators remain at a safe distance, reducing accident risks.

Higher Efficiency: Faster transfer between production stages and storage areas.

Lower Costs: Minimized labor and maintenance expenses.

Scalable Solution: Adaptable to future smart factory upgrades.

Environmentally Responsible: Supports green manufacturing initiatives.