The Non-Motorized Rail Transport Cart is a manual or towed type rail-guided material handling trolley, designed for efficient movement of goods, equipment, and components along fixed rail tracks within workshops or production facilities.

This cost-effective solution provides simple structure, high load capacity, and low maintenance, making it ideal for short-distance and intermittent transport tasks in industrial environments.

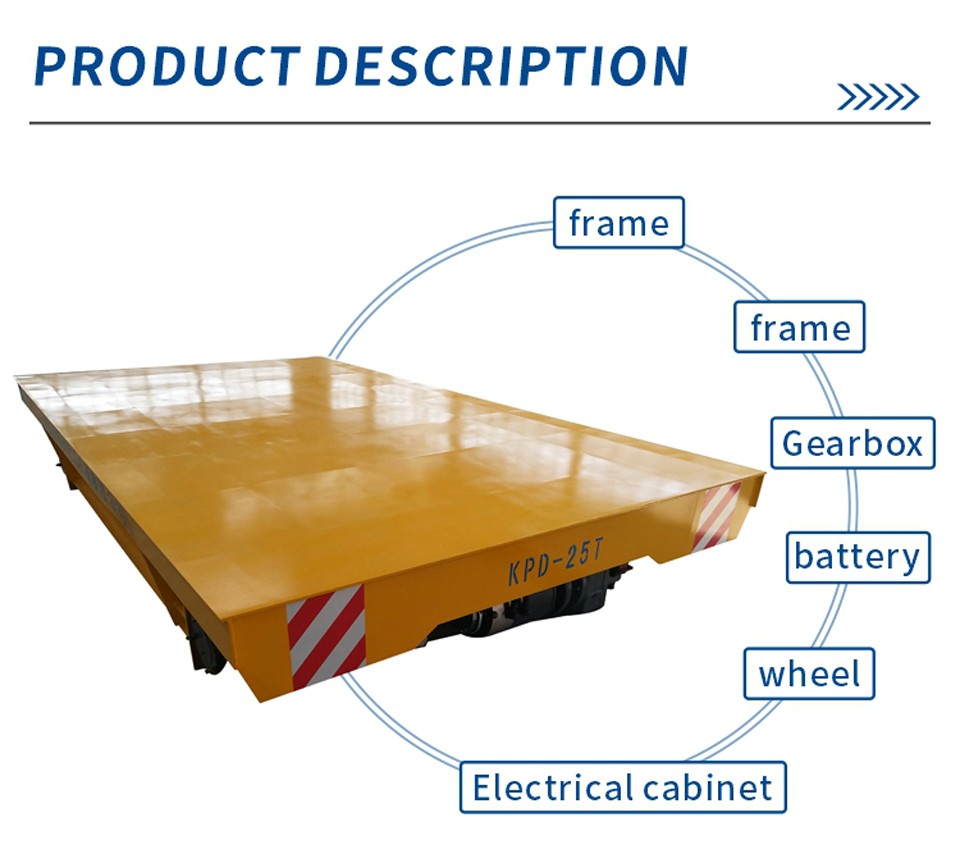

Product Overview

Unlike powered transfer carts, this non-motorized version does not include a drive motor. It is moved manually or towed by other equipment such as forklifts, winches, or powered transfer vehicles.

The cart runs smoothly on steel rails, ensuring stable and guided movement, and is suitable for flat workshop floors or interbay transfer lines.

Structural Features

Load Capacity: 1–150 tons (customizable).

Platform Type: Flat deck or custom fixture design for specific materials.

Frame Structure: Heavy-duty welded steel frame (Q235B / Q345B).

Wheel Material: High-strength forged steel or cast steel with wear-resistant treatment.

Rail Type: P43 / P50 / QU series standard steel rails.

Running Mode: Manual push or towline connection to a powered cart.

Design Advantages

Simple & Reliable Construction

No electrical or drive components — easy to operate and maintain.

Compact design suitable for narrow workshop spaces.

High Load Capacity

Designed for heavy-duty transport, capable of handling large molds, parts, or steel materials.

Reinforced frame ensures structural integrity under high loads.

Flexible Movement Options

Can be linked with powered carts, towed by forklifts, or pushed manually depending on load weight.

Optional tow bar, coupler, or drawbar for easy connection to other vehicles.

Low Cost & Maintenance-Free

No motors, batteries, or cables — minimal maintenance required.

Economical solution for short-distance, low-frequency transport.

Applications

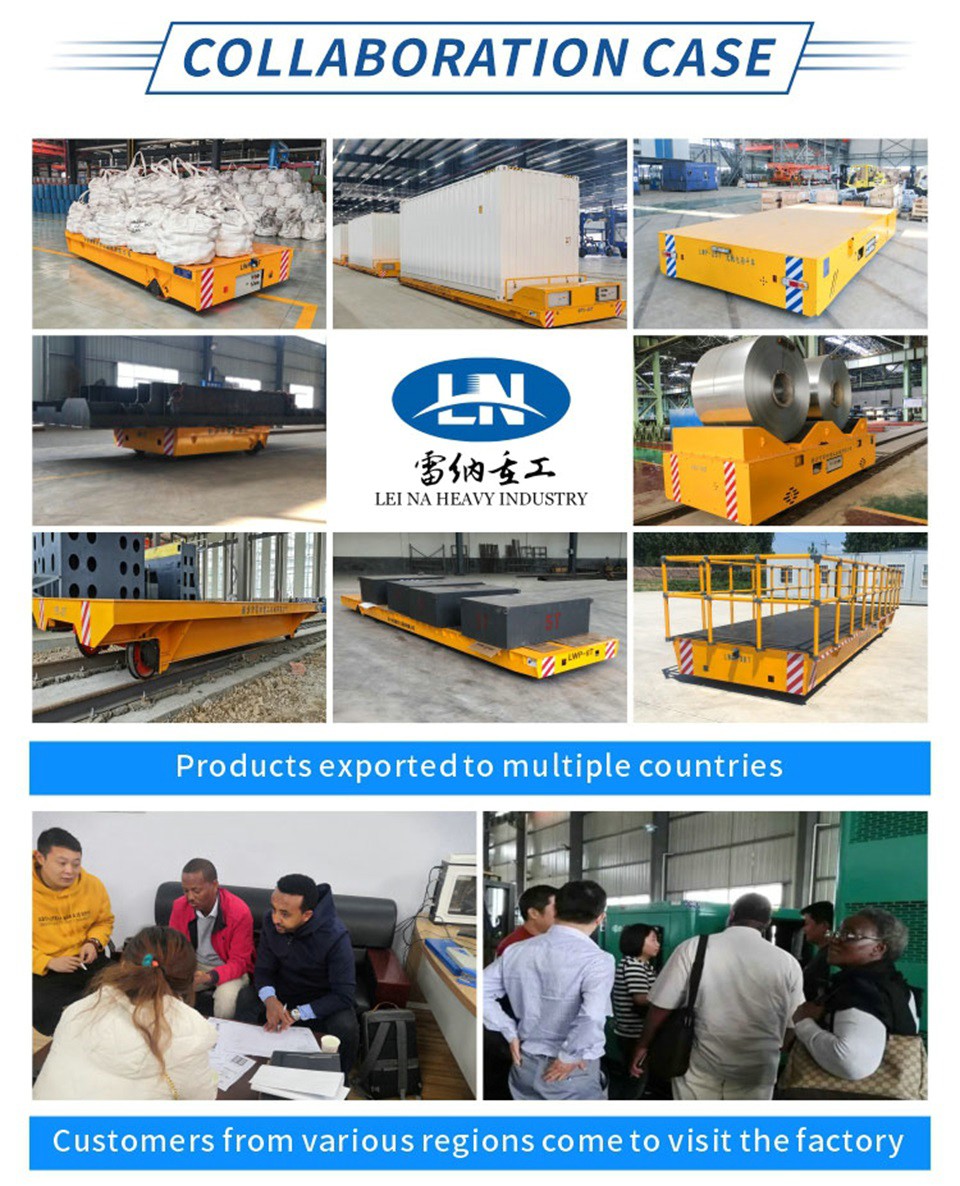

Machinery manufacturing workshops – transporting machine components and tools.

Metal and steel plants – moving steel plates, sections, or coils.

Mold and die industry – transfer of molds between workstations.

Assembly and maintenance lines – interbay material movement.

Warehouse logistics – manual cargo transfer within storage areas.