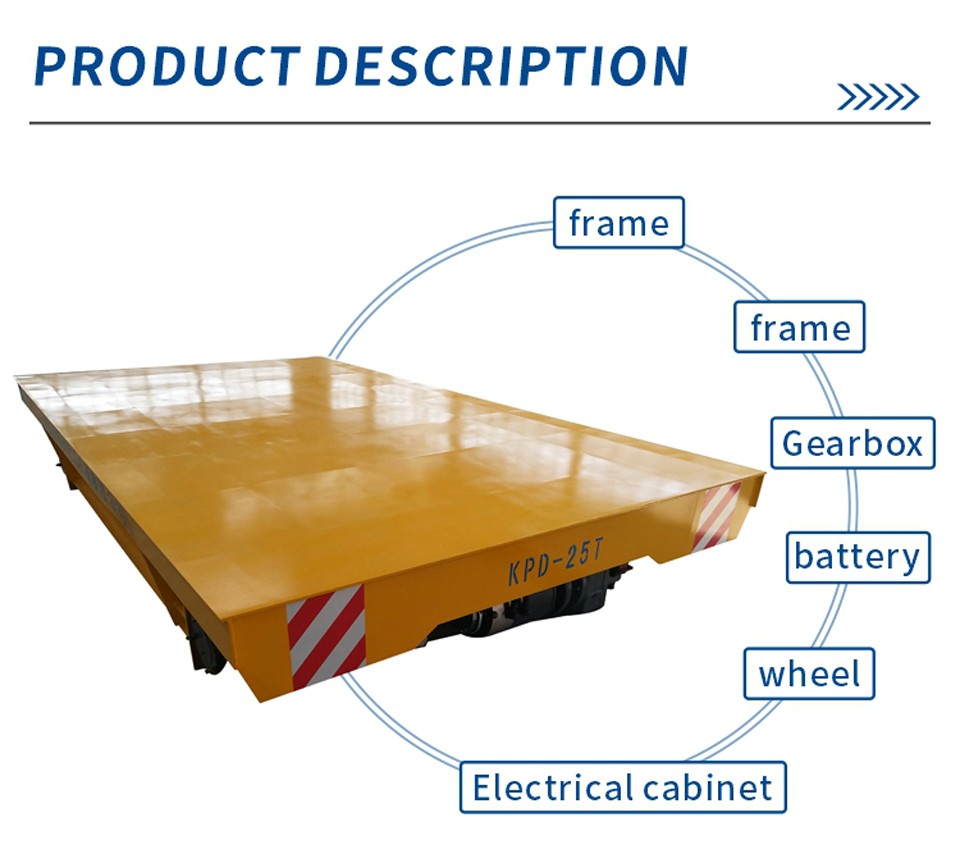

The Steel Plant Electric Rail Powered Material Transfer Equipment is a specialized industrial transport solution designed for efficient movement of heavy materials within steel plants, foundries, and metallurgical workshops.

Powered directly from electrified rails, this system provides a stable, continuous, and high-capacity power supply, making it ideal for high-temperature, high-load, and long-cycle operations commonly found in steel production environments.

With its rugged structure, precision drive system, and customizable configurations, the equipment ensures safe, reliable, and efficient handling of steel billets, molds, ladles, and other heavy components.

Working Principle

The trolley operates using a low-voltage rail power supply system (KPD series).

The AC 380V main power is stepped down to safe 36V or 48V through a transformer.

Power is transmitted through the rails and wheels directly to the traction motor, enabling continuous operation without battery charging.

Equipped with a reducer gearbox and control unit, the cart moves smoothly along fixed rails, ensuring stable speed and precise positioning.

This design provides continuous energy, low maintenance, and long service life, making it perfect for high-demand industrial environments.

Key Features

Continuous Electric Power Supply

Powered directly from the rail — no downtime for charging.

Designed for 24-hour continuous operation in demanding plant conditions.

Heavy-Duty Load Capacity

Standard models from 1 ton to 300 tons, customizable as required.

High-strength welded steel frame ensures durability and deformation resistance.

Efficient and Stable Operation

AC traction motor with VFD control allows adjustable speed and smooth movement.

Capable of long-distance travel with constant performance.

Enhanced Safety Protection

Built-in emergency stop, alarm system, and limit switches.

Optional infrared anti-collision sensors and automatic braking system.

Technical Description (Text Format)

Model Type: KPD Series Electric Rail Powered Transfer Equipment

Rated Load Capacity: 1–300 tons (customized)

Power Supply: 36V/48V low-voltage rail power

Drive Motor: AC motor with reducer gearbox

Speed Range: 0–20 m/min adjustable

Table Size: Customizable according to material type

Control Mode: Remote control / Pendant control / PLC automation

Safety Devices: Alarm, limit switch, emergency stop, overload protection

Environment: High-temperature, heavy-duty workshop operation