The Electric Double Deck Rail Transfer Trolley is a specialized heavy-duty material transport system designed for industrial environments requiring multi-level load handling.

Equipped with a dual-layer working platform, it allows operators to transport, separate, and organize different materials or components simultaneously — improving space utilization and operational efficiency.

Mounted on fixed steel rails, this trolley provides smooth, stable, and reliable transportation of heavy materials such as molds, steel structures, machine components, and large assemblies.

It is commonly used in automotive plants, steel mills, heavy machinery workshops, shipyards, and fabrication industries.

Structure & Working Principle

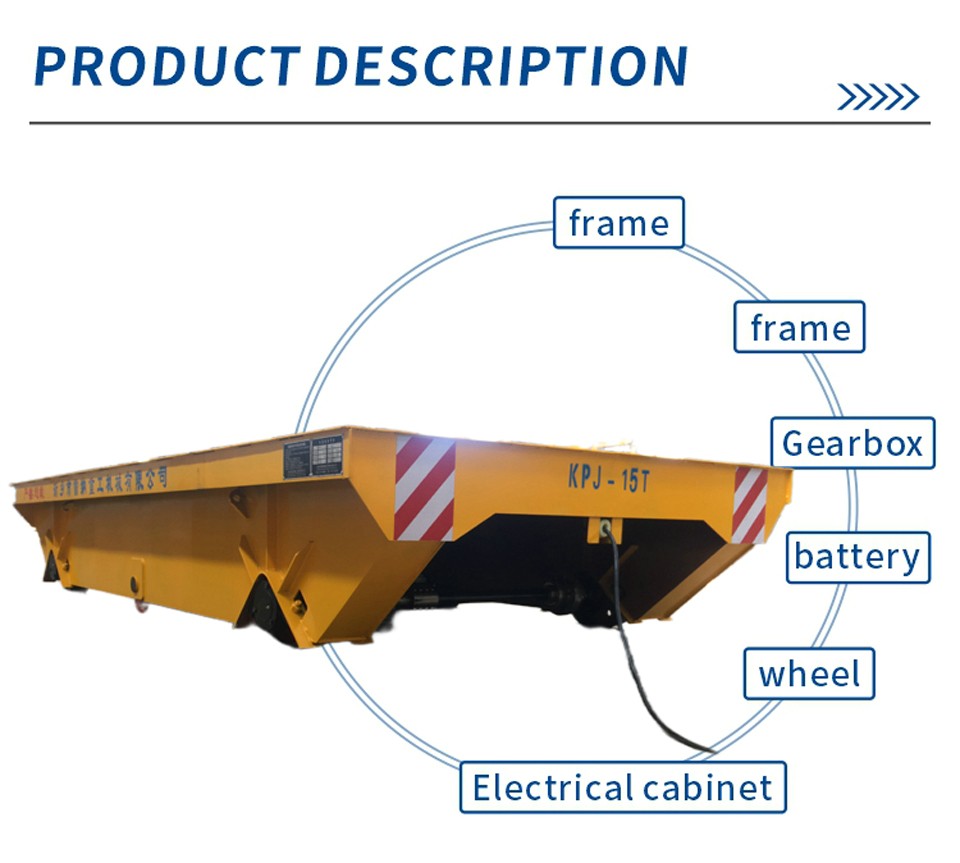

This transfer trolley consists of:

A robust welded steel frame with high load-bearing capacity.

Dual-layer (double-deck) platforms that can be fixed or movable depending on requirements.

Electric drive system powered by battery, cable reel, or sliding contact line.

Rail-mounted wheel assemblies for precise and safe guided movement.

The upper and lower decks can be used for:

Separating different materials or tools,

Multi-level assembly operations,

Integrating automated loading and unloading systems.

Key Features

Electric Drive System

Available with battery power, cable reel, or sliding contact line.

Provides steady torque and efficient energy output.

Suitable for both indoor and semi-outdoor operations.

Double-Deck Platform Design

Upper and lower decks designed to handle different material types or process stages.

Can be customized in height, spacing, and structure.

Ideal for dual-purpose workflows such as storage + transport, or loading + sorting.

Heavy-Duty Construction

Industrial-grade steel frame, designed for loads up to 300 tons.

Finite Element Analysis (FEA) ensures frame rigidity and safety.

Built to withstand long-term operation under high-stress conditions.

Flexible Control Modes

Wired pendant control for on-site operation.

Wireless remote control for safe distance handling.

PLC or automation integration for smart factory applications.

Variable frequency drive (VFD) for smooth start/stop and precise speed control.

Comprehensive Safety Systems

Emergency stop switches on both sides.

Audible and visual warning alarms during movement.

Overload and overcurrent protection.

Limit switches to prevent over-travel.

Optional infrared anti-collision sensors or laser obstacle detection.

Customizable Options

Fixed or lifting upper deck (manual or hydraulic).

Guard rails or fences for safety on both decks.

V-frame or roller deck for cylindrical materials.

Integrated conveyor system for automated transfer.

Technical Description

Power Supply: Battery / Cable Reel / Sliding Contact Line

Load Capacity: Standard 10–300 tons (custom options available)

Platform Design: Two-level steel decks, each customizable in size and height

Speed Range: 0–20 meters per minute, adjustable via frequency control

Control Method: Pendant, Remote, or PLC automated system

Track Type: Standard steel rails (P18–P50)

Running Distance: Configurable according to workshop layout

Safety Devices: Alarms, Emergency Stop, Limit Switches, Anti-Collision System

Operating Temperature: -20°C to +50°C, suitable for industrial environments