The Cable Reel Power Supply Motorized Rail Transfer Trolley is a heavy-duty industrial material handling vehicle designed to move large loads, equipment, or raw materials across workshops and production lines.

Powered by an industrial-grade cable reel system, this rail-mounted trolley delivers continuous and reliable electrical energy, making it ideal for medium to long-distance transportation within factories, assembly workshops, and warehouses.

Built for high efficiency and durability, it is widely used in industries such as automotive manufacturing, steel mills, heavy machinery, shipbuilding, and material processing plants.

Working Principle

The trolley receives power directly from an AC 380V supply through a motor-driven cable reel mounted underneath or at the side of the vehicle.

As the trolley moves along the rail, the cable reel automatically winds and unwinds the cable, ensuring constant power delivery to the traction motor and control system.

This setup allows for:

Stable and uninterrupted power transmission

High torque output for heavy loads

Reduced maintenance compared to battery systems

Main Features

Continuous Cable Power Supply

The integrated automatic cable reel ensures stable power during movement.

No need for charging — suitable for 24/7 continuous operation.

Ideal for fixed rail paths up to 200 meters in length.

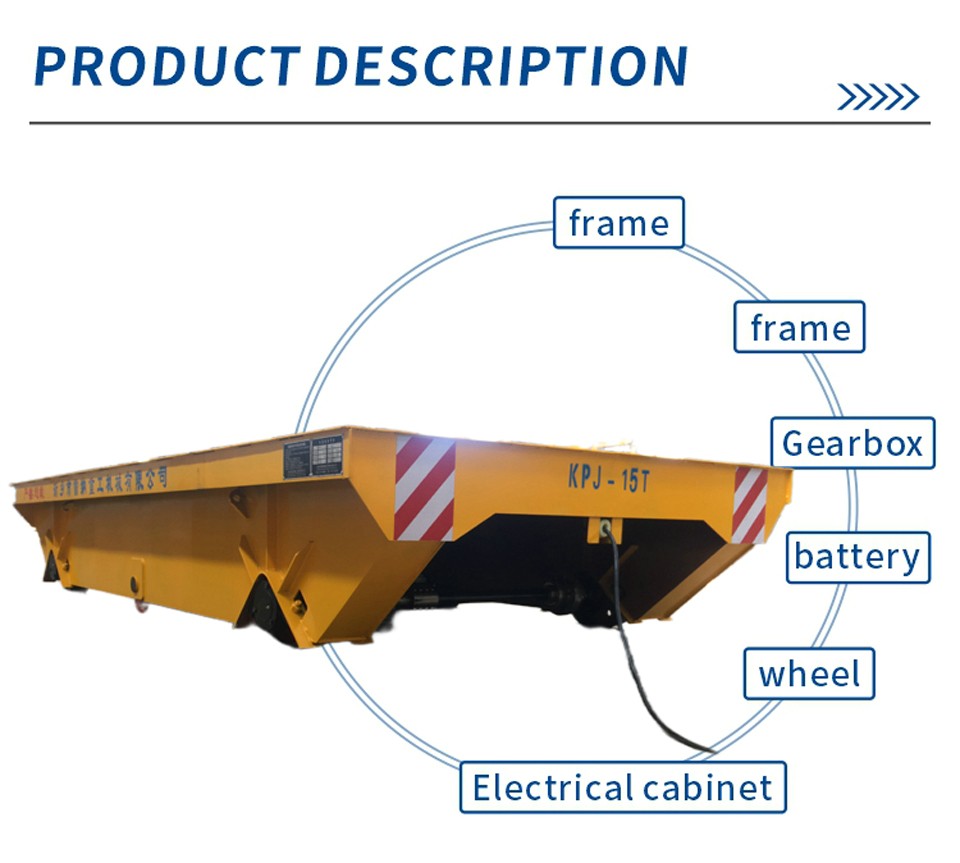

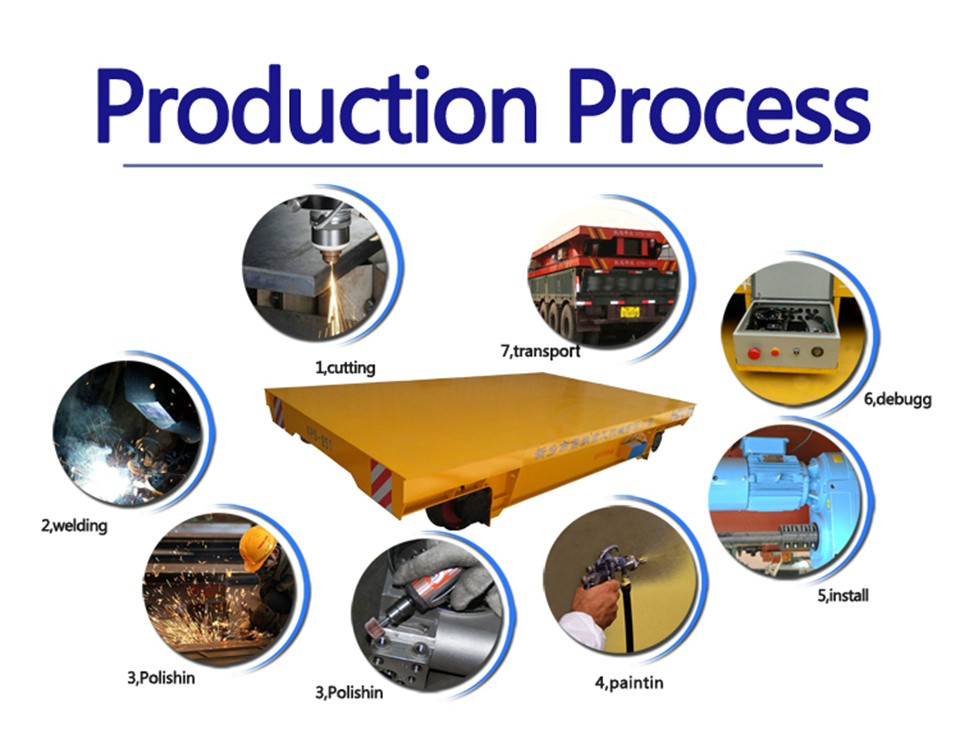

Heavy-Duty Structural Design

Made from high-strength welded steel to withstand industrial load capacities ranging from 1 ton to 300 tons.

The solid wheel assembly provides smooth, vibration-free motion on steel rails.

The rugged frame ensures long service life even under high load cycles.

Smart Control System

Wired pendant control for on-site precision handling.

Wireless remote control option for safe distance operation.

Variable Frequency Drive (VFD) ensures smooth acceleration and deceleration.

Optional PLC automation for integration with production line systems.

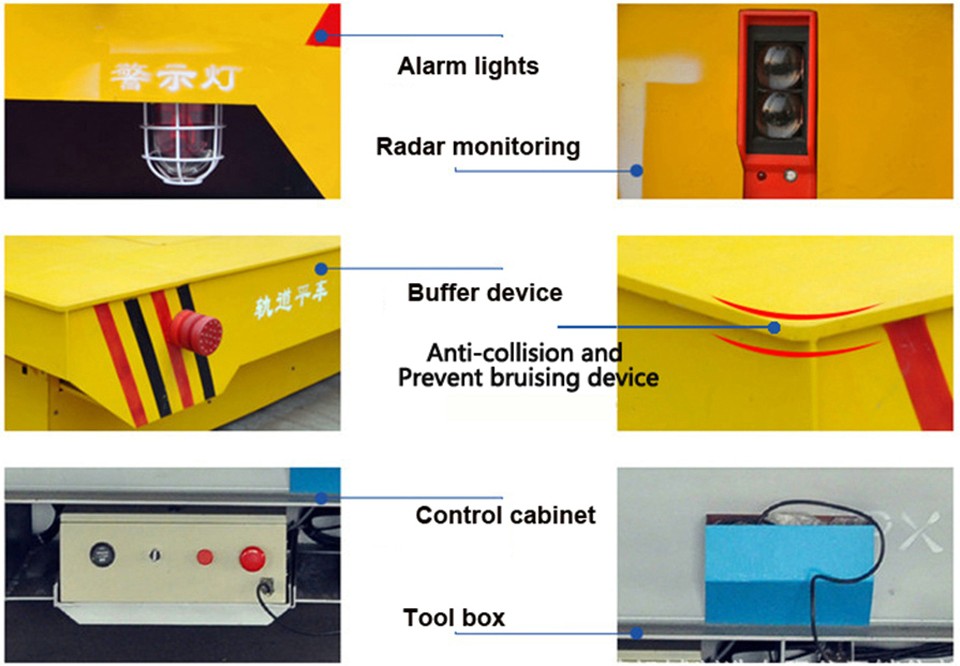

Safety & Protection Systems

Emergency stop buttons and audible-visual alarms for operator safety.

Overcurrent and cable tension protection to prevent damage.

Limit switches at track ends to avoid over-travel.

Optional infrared or laser anti-collision sensors for added security.

Customizable Platform Options

Flat deck for general material transport.

V-frame deck for steel coils, rolls, or cylindrical items.

Guard rail deck for enhanced load security.

Hydraulic lifting or tilting platform for ergonomic loading/unloading.

Roller conveyor top for seamless integration with production or assembly lines.

Technical Description

Power Source: Industrial-grade cable reel system (AC 380V)

Load Capacity: Available from 5 tons to 300 tons (customizable)

Table Size: Customized to fit load dimensions and working conditions

Speed Range: 0–20 meters per minute (adjustable)

Rail Gauge: Customized to workshop layout (P18–P50 steel rail)

Control Options: Wired pendant / Wireless remote / PLC control

Operation Distance: Up to 200 meters recommended

Safety Devices: Emergency stop, limit switches, alarms, cable protection

Operating Environment: -20°C to +50°C, indoor or sheltered outdoor use