The Workshop Cable Powered Rail Transfer Vehicle is a high-performance industrial transport system designed to move heavy materials, machinery, and components efficiently across fixed routes inside workshops or manufacturing facilities.

Powered by an industrial-grade cable reel or drag chain system, this vehicle delivers continuous AC power supply to ensure stable, uninterrupted operation — making it ideal for high-frequency transport tasks in automotive, steel, foundry, and heavy machinery industries.

Its rail-guided structure guarantees precise movement, smooth running, and excellent safety during the transportation of large, bulky, or heavy-duty loads.

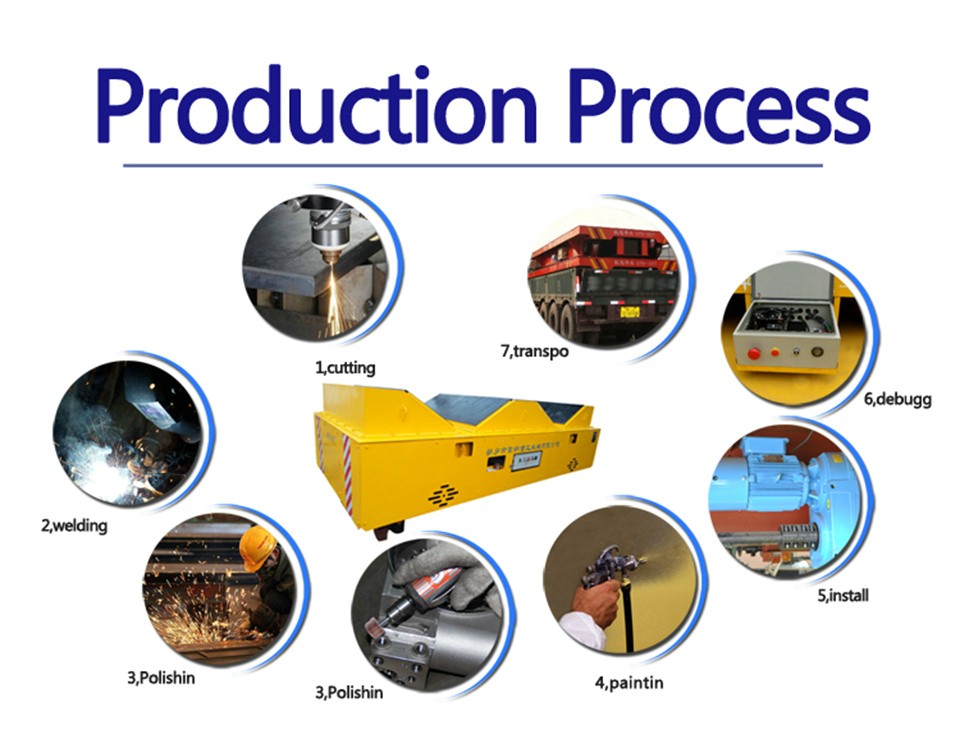

Working Principle

This transfer vehicle operates through a cable power supply system:

The vehicle is connected to a 380V AC power source via a cable reel or drag chain.

As the trolley moves along the track, the cable reel automatically winds and unwinds the cable to maintain continuous power flow.

The electric motor and control system convert electrical energy into smooth, controlled traction to move the load safely along the rail.

This configuration provides stable torque, high energy efficiency, and reliable operation over long working hours.

Main Features

Continuous Cable Power Supply

Delivers uninterrupted power through a cable reel system for consistent performance.

Suitable for medium to long rail distances (typically up to 200 meters).

Eliminates the need for batteries or frequent charging downtime.

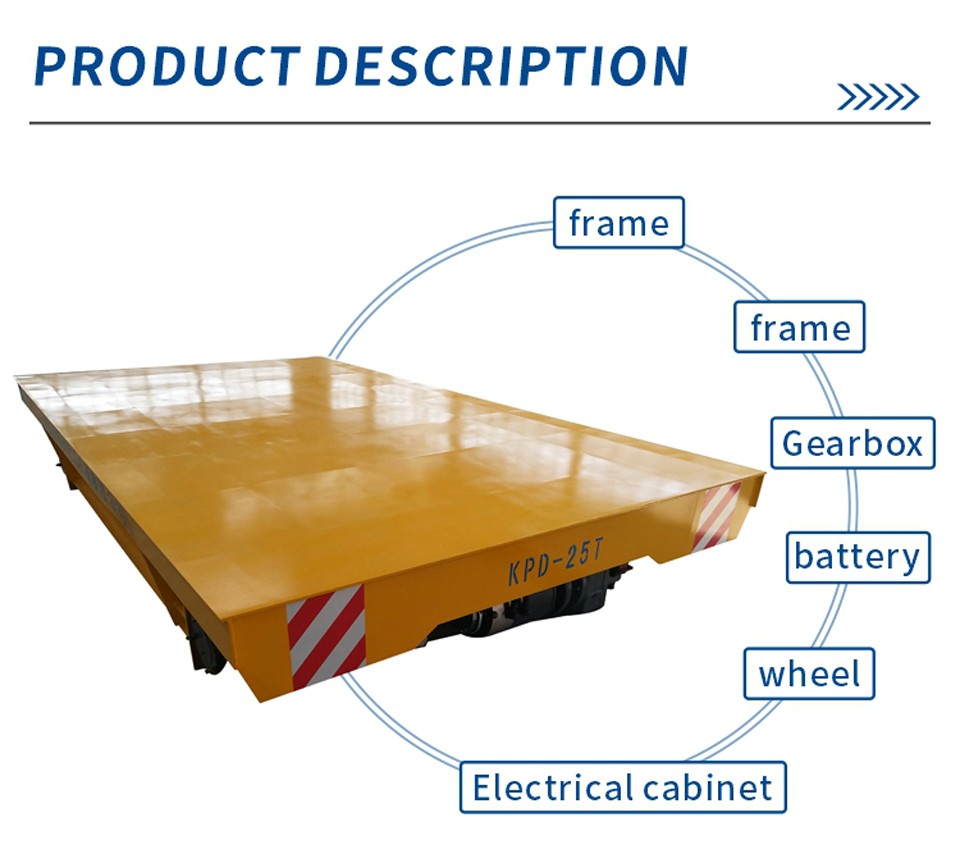

Robust Heavy-Duty Structure

Fabricated from high-strength steel plate using precision welding.

Designed for load capacities from 5 tons up to 300 tons.

Rigid structure resists deformation under heavy industrial use.

Long service life and minimal maintenance requirements.

Flexible Control System

Wired pendant control for precise operator handling.

Wireless remote control for safe and convenient long-distance operation.

Optional PLC or automatic control system for integration with workshop automation.

Variable Frequency Drive (VFD) ensures smooth acceleration and braking.

Stable Rail-Guided Movement

Travels along pre-installed steel rails (P18–P50) to ensure accurate positioning.

Rail guidance minimizes vibration, improving safety for fragile or valuable loads.

Ideal for workshops, assembly lines, and production facilities requiring fixed-route transfer.

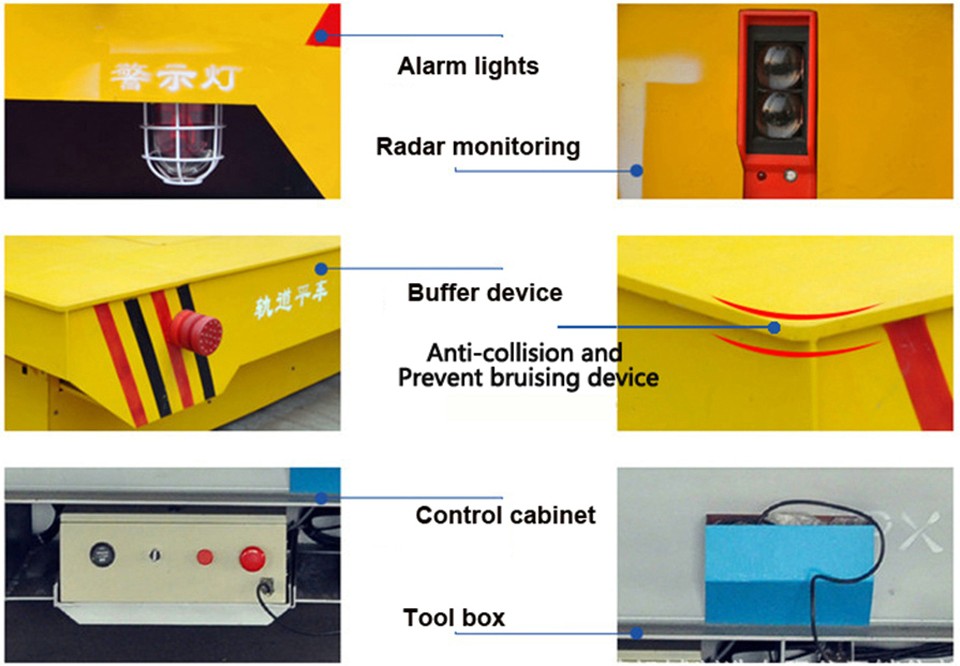

Comprehensive Safety Protection

Emergency stop buttons on both sides.

Audible and visual alarms during motion.

Overcurrent and overload protection for electrical safety.

Limit switches to prevent over-travel or derailment.

Optional infrared or laser collision avoidance sensors for added protection.

Technical Description

Power Source: AC 380V via cable reel or drag chain

Rated Load Capacity: 5 to 300 tons (customizable)

Platform Size: Custom-built to match material dimensions and workshop layout

Travel Speed: 0–20 meters per minute, adjustable via VFD

Control Mode: Pendant, Remote, or PLC automation

Track Type: Steel rails, customized gauge based on plant design

Power Transmission Distance: Up to 200 meters

Safety Features: Emergency stop, alarms, limit switches, cable management system

Operating Environment: Indoor or sheltered outdoor, -20°C to +50°C