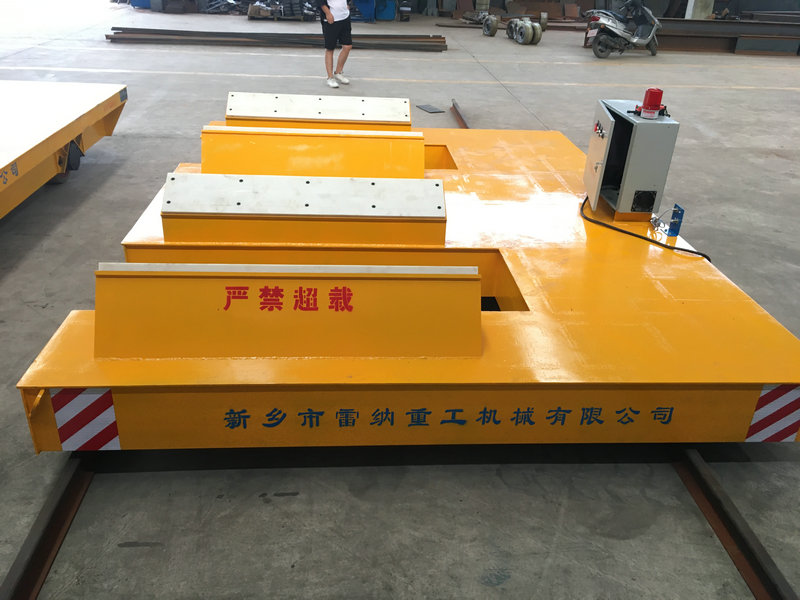

The KPT Series Cable Powered Electric Flat Car is a rail-mounted material transfer vehicle designed for heavy-duty industrial transportation.

Powered by an AC cable supply, it offers stable, continuous power delivery for long operation periods—making it ideal for workshops, assembly lines, warehouses, and manufacturing plants.

This transfer cart is built for transferring molds, steel structures, machinery, and raw materials between different bays or process stations.

Its low-voltage AC drive system ensures smooth, safe, and reliable operation across short or medium-distance routes.

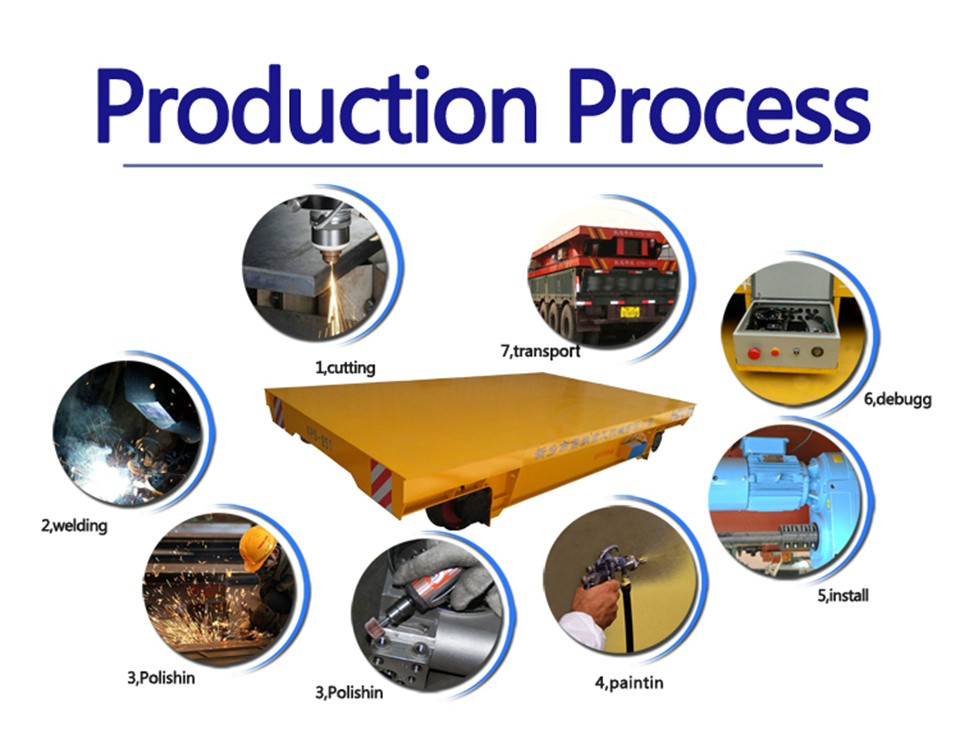

Working Principle

The KPT cable-powered flat car operates through an electric cable reel or drag chain system:

The cart receives AC power directly from an external power supply (typically 380V).

The cable is automatically wound and released during the car’s movement, ensuring continuous power feed.

The current passes through the control system and motor drive, propelling the cart along the rail path.

This system guarantees stable torque output, high energy efficiency, and minimal downtime, ideal for high-frequency material transfer tasks.

Key Features

Stable Cable Power Supply

Continuous and steady AC power ensures uninterrupted operation.

No need for battery charging or replacement.

Suitable for medium to long-distance fixed routes (generally within 200 meters).

Rugged Steel Construction

Built with high-strength welded steel frames, providing excellent load-bearing capability.

Designed to handle heavy industrial loads (from 1 ton up to 300 tons).

Equipped with shock-resistant wheels for smooth operation on rails.

High Efficiency & Reliability

Direct cable power offers higher efficiency than battery systems.

Simple electrical structure for easy maintenance.

Capable of continuous 24-hour operation in demanding production environments.

Customizable Design

Platform size, load capacity, rail gauge, and speed can all be custom-engineered.

Deck options include:

Flat platform (for general materials)

V-frame (for steel coils or cylindrical products)

Guard rail or lifting table (for added load security)

Smart Control Options

Wired pendant control for precise movement.

Wireless remote control for convenient and safe operation.

Variable frequency drive (VFD) for smooth acceleration and braking.

Optional PLC automation for integration with smart factory systems.

Safety & Protection

Emergency stop buttons and alarms.

Overload and short-circuit protection.

Cable tension management to prevent cable wear.

Limit switches for safe travel range control.