The Battery Operated 30 Ton Multi-Directional Transfer Vehicle is a high-performance material handling solution designed for industrial workshops, manufacturing plants, and heavy-duty production lines.

Equipped with an advanced battery-powered drive system and 360° multi-directional steering, it enables free, flexible, and precise movement of large loads — without the need for rails or fixed pathways.

This vehicle is ideal for mold transport, machinery handling, steel fabrication, and assembly line logistics, offering efficiency, safety, and mobility in one robust system.

Key Features

Battery Powered Drive System

Operates independently — no cables or external power needed.

Long-lasting lithium or lead-acid battery ensures 6–8 hours of continuous work.

Zero-emission, low-noise, and maintenance-friendly operation.

Multi-Directional Steering Function

Capable of forward, backward, lateral, and diagonal movement.

Supports 360° in-place rotation for effortless navigation in narrow spaces.

Perfect for dynamic workshops with limited maneuvering room.

Heavy-Duty Load Capacity

Engineered with a reinforced steel frame for maximum strength and stability.

Rated for 30 tons of uniform load, ensuring safe and smooth operation.

Optional custom fixtures, lifting platforms, or support frames available.

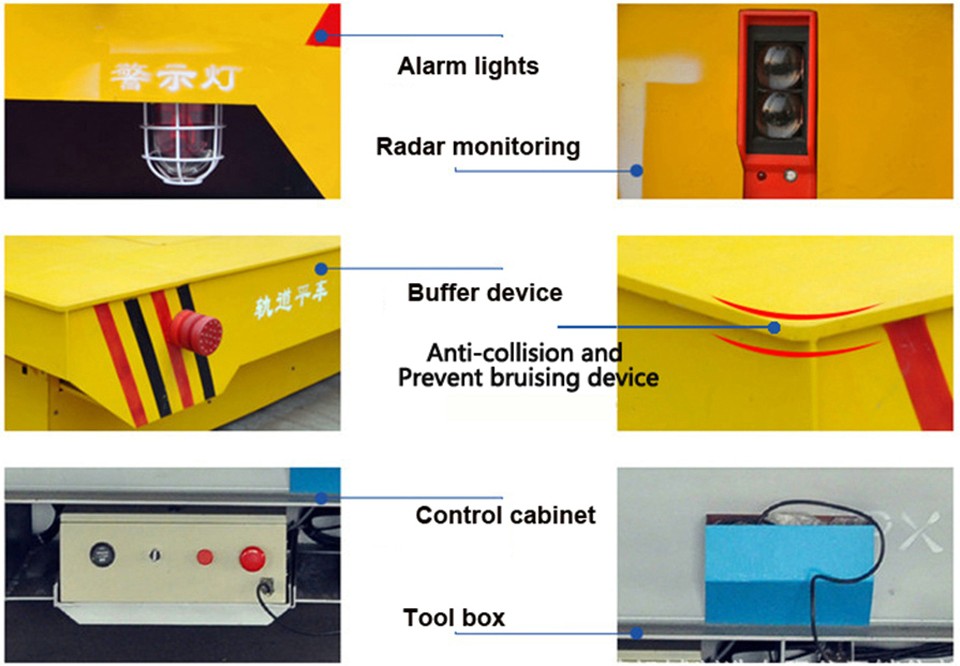

Smart Control System

Controlled via wireless remote or wired pendant for easy operation.

Smooth acceleration and variable-speed control protect the load during movement.

Optional PLC automation, laser navigation, or magnetic guidance for advanced functions.

Safety and Protection

Equipped with emergency stop buttons, acoustic-light alarms, and anti-collision sensors.

Optional laser obstacle detection for enhanced operational safety.

Conforms to CE and ISO industrial safety standards.

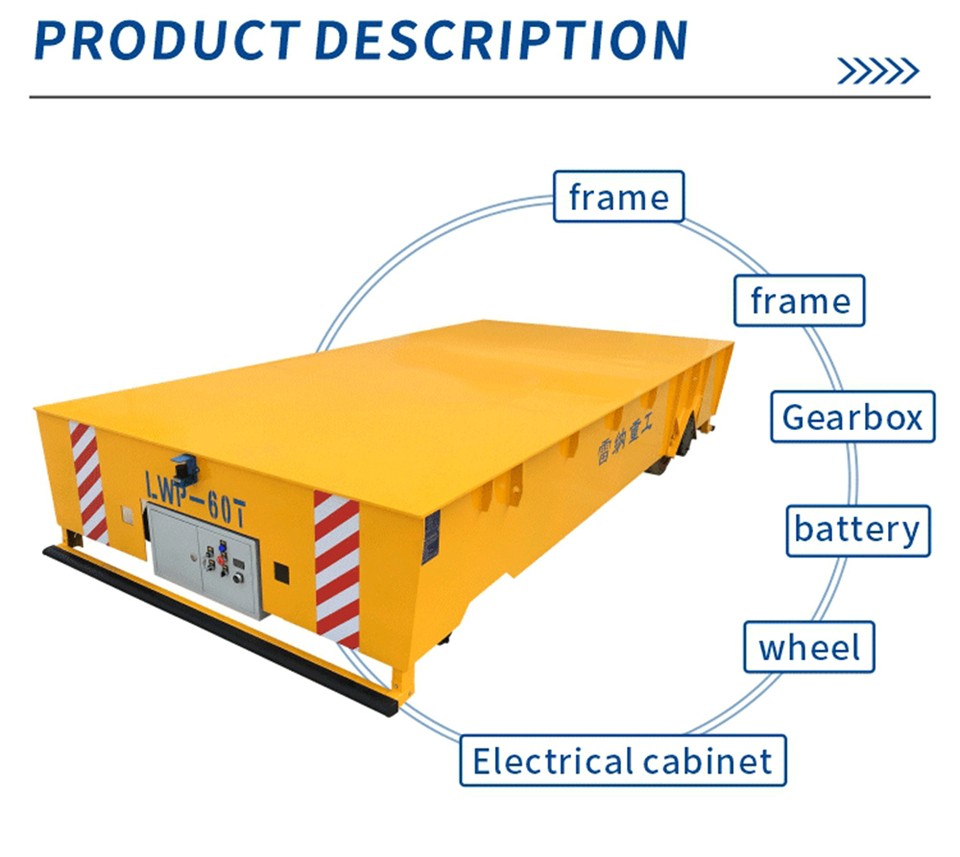

Technical Description

The 30-ton transfer vehicle uses a battery-driven traction system with independent steering modules for omnidirectional motion.

Its travel speed is adjustable between 0–30 meters per minute, providing both precision control and high-efficiency transport.

The battery system delivers consistent power for 6–8 hours, with a standard charging time of about 5 hours.

The heavy-duty chassis is made from high-strength welded steel, capable of handling concentrated or distributed loads safely.

It can be customized to suit specific industrial applications, including mold transport, coil handling, and assembly logistics.

Typical Applications

Machinery Manufacturing – Transport of large equipment and components.

Automotive Industry – Transfer of car molds, dies, and body assemblies.

Steel & Metal Processing – Handling of coils, plates, and heavy parts.

Aerospace & Energy Sector – Movement of precision equipment or structural assemblies.

Warehouse Logistics – In-plant transport of heavy pallets or tools.