The Modular Transfer Cart for Factory Material Handling Solutions is an innovative, flexible, and heavy-duty transport system designed to optimize internal logistics and production efficiency in modern manufacturing facilities.

Built on a modular structural platform, this cart can be custom-configured to meet specific load, size, and operational requirements — making it ideal for multi-purpose material transport, assembly operations, and automated logistics systems.

Product Overview

Unlike traditional fixed-design transfer carts, the modular transfer cart is built with a universal chassis platform that supports multiple configurations:

battery-powered, rail-mounted, trackless, omnidirectional, or even hydraulic-lifting types.

This modular concept allows users to easily adapt the system to different materials, working environments, and automation levels, making it a cost-effective and scalable solution for factories aiming to modernize their production logistics.

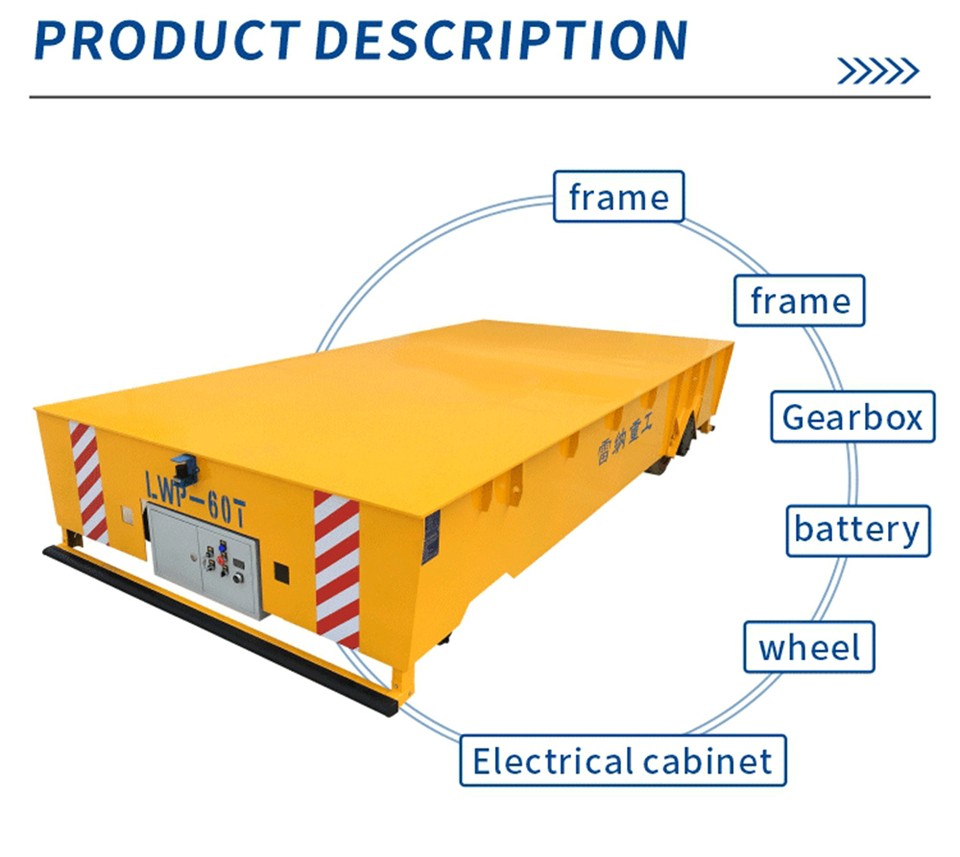

Main Technical Features

Load Capacity: 1–300 tons (modular, customizable).

Power Supply Options: Battery, cable reel, low-voltage rail, or hybrid.

Platform Type: Flatbed, V-frame, roller conveyor, or lift table.

Drive System: Dual electric motor drive or servo-controlled traction system.

Steering Type: Straight, steering wheel, or omnidirectional Mecanum design.

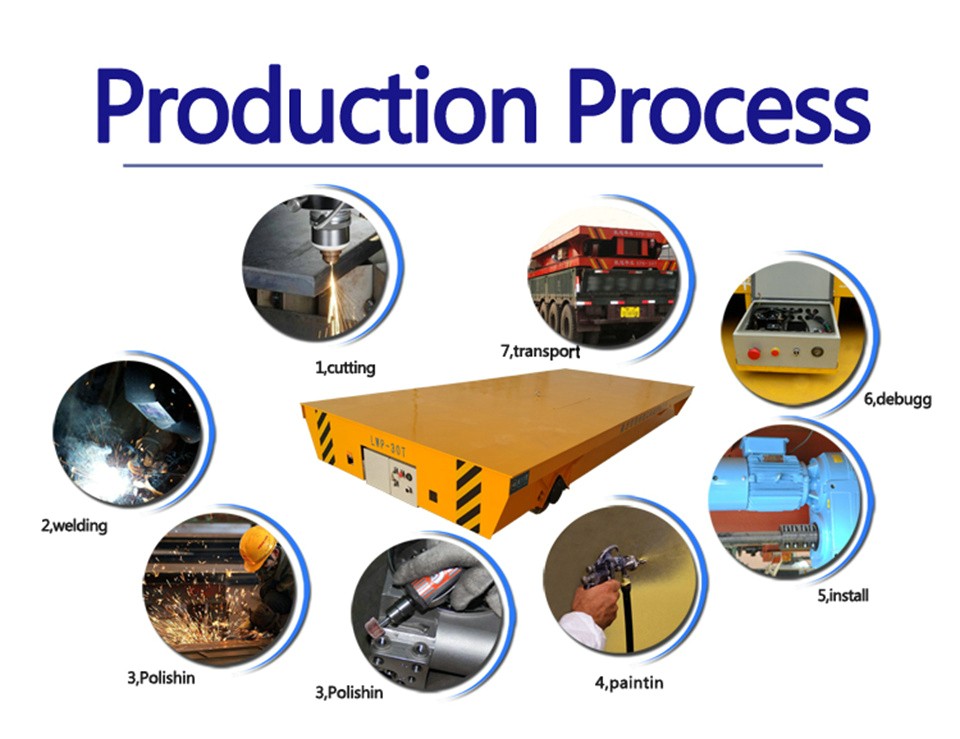

Frame Structure: Modular welded steel chassis for structural adaptability.

Operation Mode: Remote control, onboard panel, or automatic PLC navigation.

Control System: Manual, semi-automatic, or fully automated with smart sensors.

Performance Advantages

Modular Design Concept

Enables quick customization for different payloads, power systems, and platform structures.

Allows easy integration into existing production lines or future automation upgrades.

Flexible Power Options

Supports battery, cable, or low-voltage rail power, depending on site conditions.

Optional hybrid systems for extended endurance and continuous operation.

Precision and Reliability

High-torque motors and soft-start controllers ensure stable and precise movement.

Designed for heavy-duty continuous operation in industrial environments.

Scalable Automation

Can be configured as a manual or automatic system.

Compatible with PLC, AGV, or MES system integration for smart factory logistics.

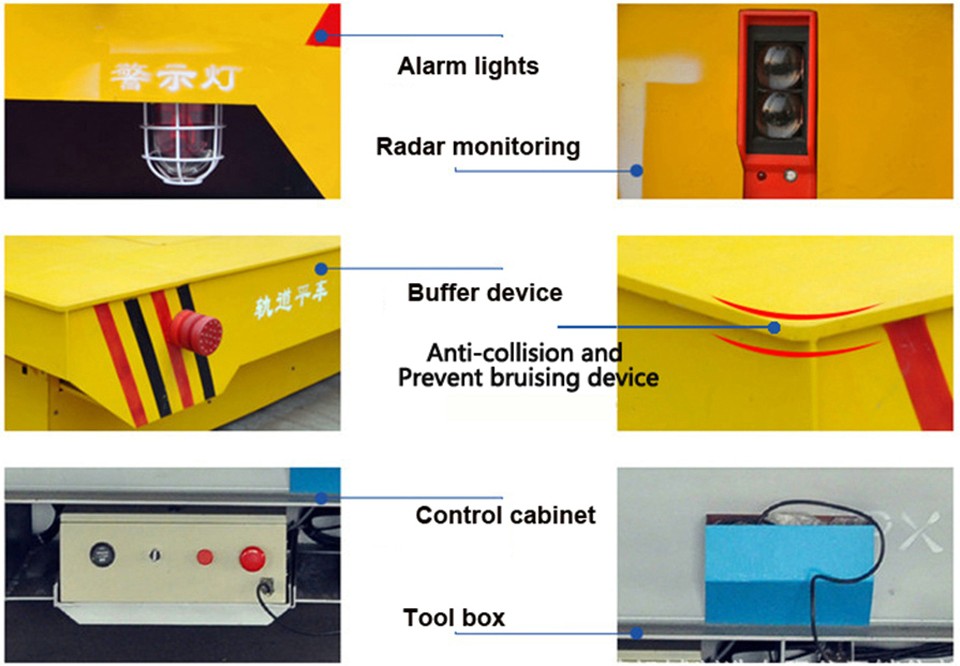

Enhanced Safety & Ergonomics

Equipped with emergency stop, collision avoidance sensors, and visual warnings.

Optional camera system and load monitoring for intelligent safety control.

Applications

Automotive & Aerospace Manufacturing — transport of large components, assemblies, and jigs.

Steel & Metal Fabrication — handling heavy plates, coils, and welded structures.

Mold & Tool Industry — movement of molds, dies, and mechanical equipment.

Machinery Assembly Lines — modular carts synchronized for large item assembly.

Smart Warehouses — automated interbay and production-to-storage material flow.