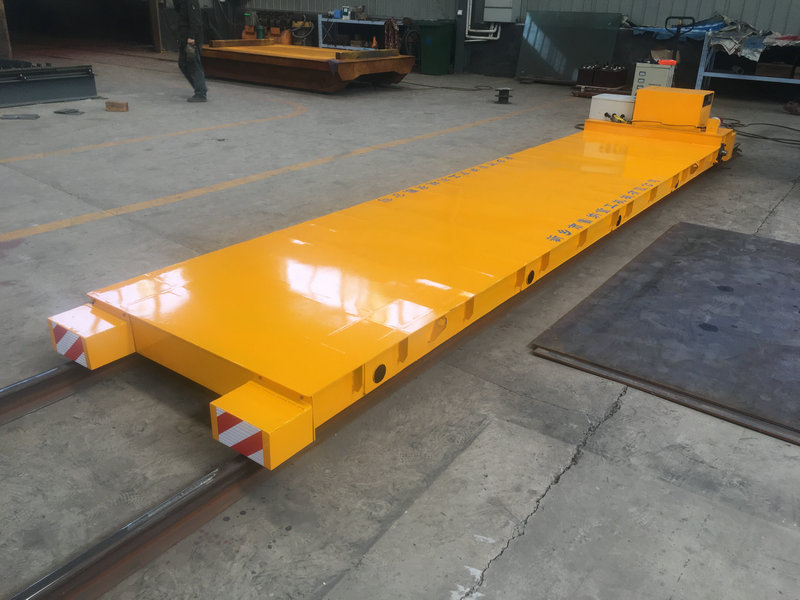

The 5 Ton Interbay Low Voltage Rail Driven Coil Transfer Trolley is a safe, efficient, and energy-saving rail-guided transport vehicle specially designed for transferring steel coils, aluminum rolls, or other cylindrical materials between production bays (interbay transport).

Powered directly by low-voltage rail electricity, this trolley eliminates the need for cables or batteries, offering continuous operation, smooth movement, and high reliability for industrial environments.

It is widely applied in steel plants, rolling mills, aluminum factories, and metal processing workshops, where precise and frequent coil handling is required.

Working Principle

The trolley operates using a low-voltage power supply system (36V / 48V / 72V) integrated into the rails.

A special power pickup device (carbon brush or conductive shoe) collects the current from the rails and feeds it to the onboard control system and traction motors.

The motors then drive the wheels to move the trolley smoothly along the rails — achieving safe, stable, and automatic power delivery without cables or external connections.

This KPD series low-voltage rail system is ideal for medium-to-long distance operations (typically ≤200 meters).

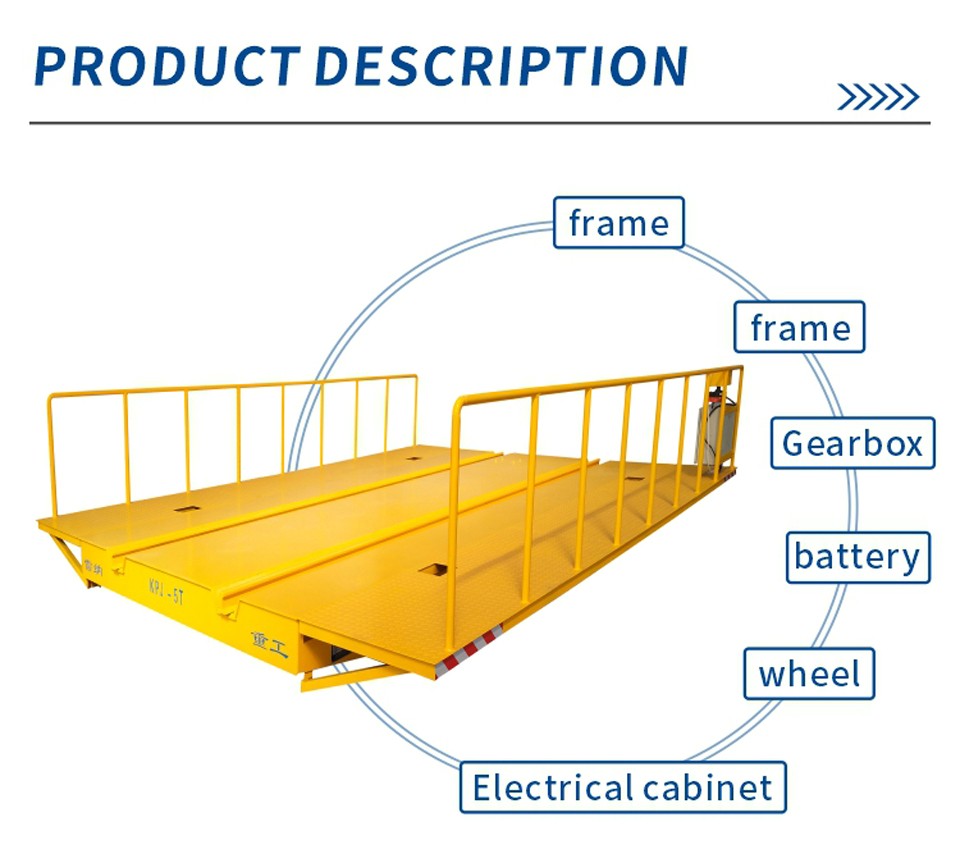

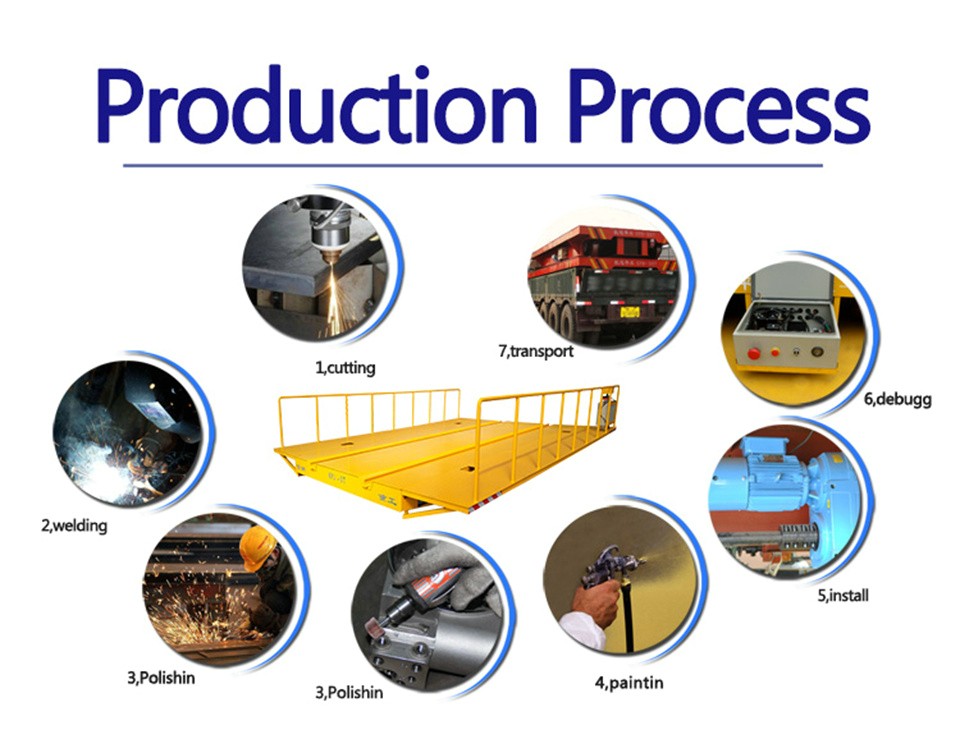

Structural Features

Load Capacity: 5 tons (optional up to 300 tons).

Frame Construction: Heavy-duty welded steel frame (Q235B / Q345B).

Rail System: Insulated dual-rail structure for safe power conduction.

Drive Mode: Dual-motor AC drive with gearbox reduction.

Wheel Material: Solid forged steel with heat treatment for long service life.

Deck Design: Optional V-frame or coil cradle to secure cylindrical loads.

Electrical & Control System

Power Supply: Low-voltage rail system (36V / 48V / 72V).

Control Mode:

Wired pendant control (standard).

Wireless remote control (optional).

Functions: Forward / Reverse / Stop / Speed Adjustment.

Safety Devices:

Overcurrent and overload protection.

Limit switches for travel endpoints.

Emergency stop button.

Optional:

Variable frequency drive (VFD) for soft start/stop.

PLC automatic control for line synchronization.

Applications

The 5 Ton Interbay Low Voltage Rail Driven Coil Transfer Trolley is commonly used in:

Steel & Aluminum Mills: Coil and roll transportation between bays.

Metal Processing Lines: Transfer of cylindrical or heavy materials.

Machinery Workshops: Movement of spools, molds, and tooling.

Warehouse Logistics: Internal handling along fixed rails.

Continuous Production Lines: Automated or semi-automated material feeding.

Advantages

Safe Low-Voltage Operation: Ensures operator safety and no cable interference.

Continuous Power Supply: Ideal for frequent or continuous operation.

Stable and Quiet Running: Smooth drive system with minimal vibration.

No Cable Reel or Battery Maintenance: Reduces downtime and costs.

Customizable Design: Optional V-frame, coil cradle, or flat platform.

Eco-Friendly: Electric drive with low energy consumption and zero emissions.

Optional Configurations

Adjustable V-frame for different coil diameters.

Automatic Positioning & Stop System.

Turntable or Cross-Rail System for multi-line transfer.

PLC Control Integration with MES or SCADA systems.

Explosion-Proof or Heat-Resistant Design for special environments.

Safety Bumpers & Warning Alarms for enhanced protection.