The KPD Rail Transfer Trolley with Rollers and Hydraulic Elevator Lift is a battery-powered material handling vehicle designed for flexible, automated, and efficient movement of heavy materials along fixed rail paths within factories, workshops, and assembly lines.

Built on the proven KPD series battery rail transfer platform, this model integrates roller conveyors and a hydraulic lifting system, enabling seamless connection with production lines, conveyors, and warehouse systems.

It is ideal for material loading/unloading, height adjustment, and multi-point transfer operations in automated production environments.

Working Principle

The trolley is powered by a DC battery pack supplying energy to the traction motor and hydraulic pump.

The hydraulic lift table allows the platform to raise or lower materials for alignment with conveyors or workstations.

Built-in rollers enable automatic material transfer between the trolley and adjacent equipment.

Electric drive motors provide smooth movement along the rail, while the control system manages speed, direction, and lift height.

This design provides flexible operation, energy efficiency, and precise material positioning — perfect for intelligent logistics systems.

Key Features

Battery-Powered System

High-capacity battery ensures independent operation without cable restrictions.

Suitable for complex workshop layouts where flexible movement is essential.

Environmentally friendly, low noise, and easy to maintain.

Integrated Roller Conveyor Platform

Heavy-duty rollers installed on the trolley deck for automatic material transfer.

Enables smooth loading/unloading between production lines or workstations.

Optional motorized rollers for synchronized transfer operations.

Hydraulic Elevator Lift System

Hydraulic lifting mechanism allows vertical adjustment of the platform height.

Precise control ensures level alignment with other equipment.

Ideal for multi-level or uneven surface material transfer.

Smart Control & Safety Features

Operated via wireless remote control or pendant panel.

Optional PLC control system for automated integration with production lines.

Equipped with emergency stop, limit switches, and overload protection for safe use.

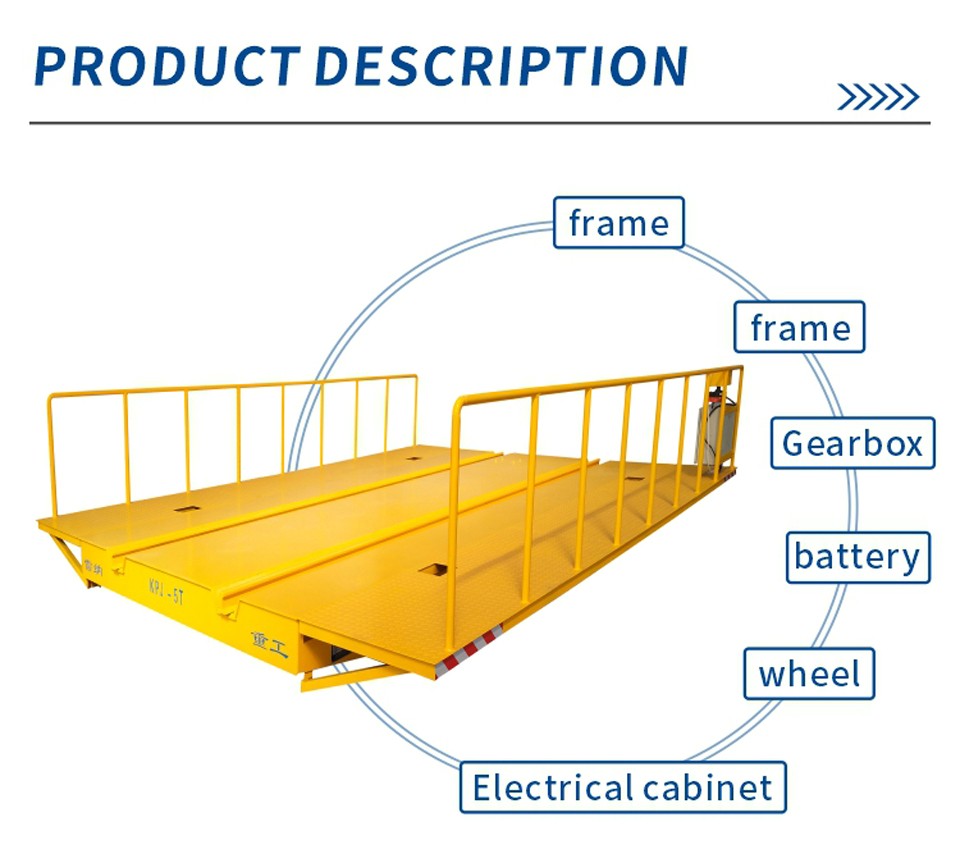

Technical Description

Model Type: KPD Battery Powered Rail Transfer Trolley with Rollers & Hydraulic Lift

Power Supply: Battery (DC 48V / 72V, capacity customizable)

Load Capacity: Typically 5–50 tons (customized on demand)

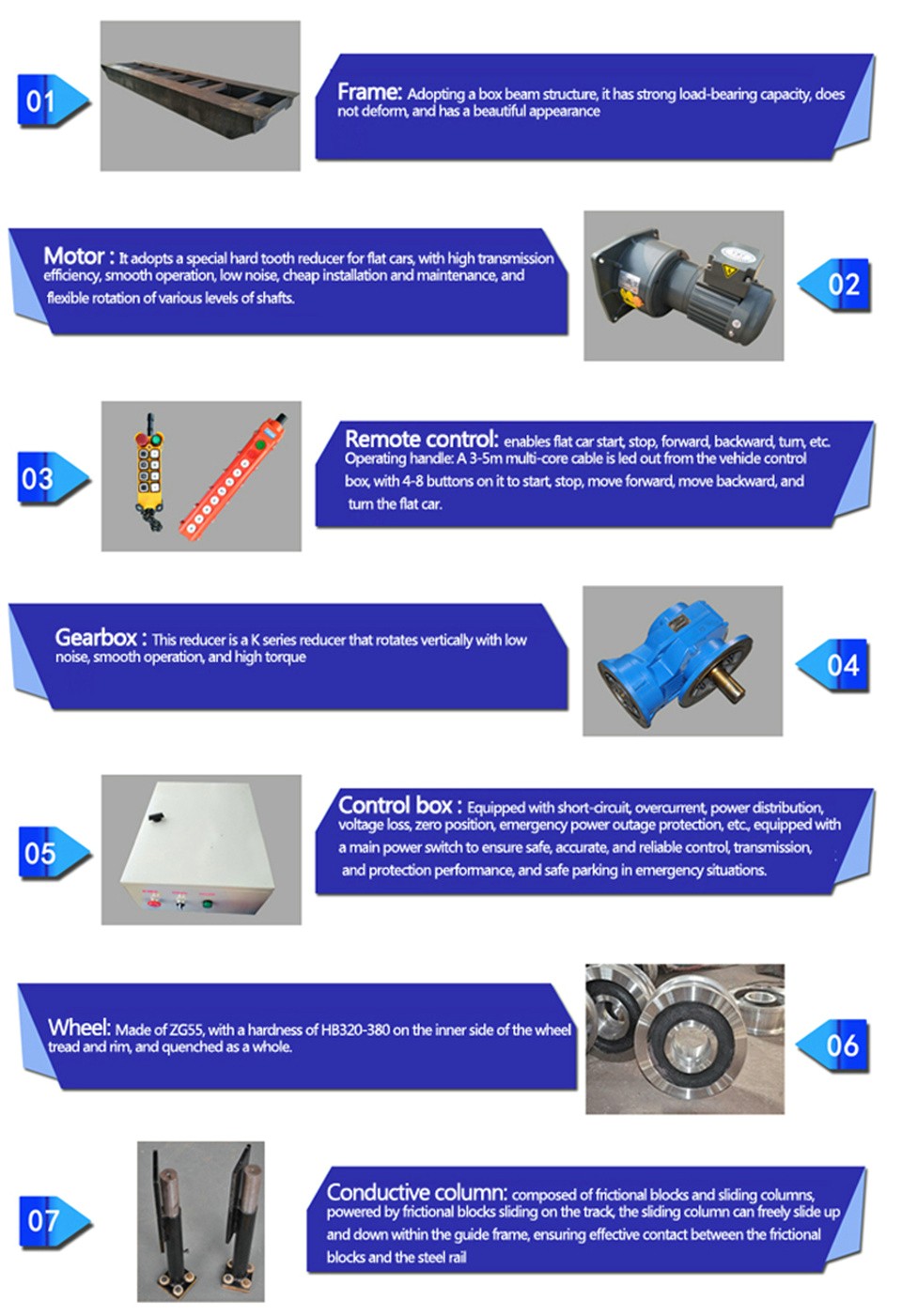

Drive Mode: DC motor drive with reduction gearbox

Running Speed: 0–20 m/min, adjustable

Hydraulic Lift Height: 200–600 mm adjustable range (custom available)

Platform Type: Flat deck with roller conveyor

Control Mode: Hand-held remote / Wired pendant / PLC automation

Safety System: Limit switch, emergency stop, alarm, overload protection

Working Environment: Indoor use, temperature -20°C to +50°C