The Robust Industrial Steel Material Handling Rail Transfer Trolley is a high-strength, rail-guided transport solution developed for steel plants, metal fabrication workshops, manufacturing facilities, and industrial warehouses.

Engineered to handle heavy steel materials with precision and safety, this trolley enables smooth, controlled, and efficient in-plant transportation of steel plates, billets, slabs, coils, and fabricated components.

With its reinforced steel construction, powerful drive system, and reliable control, the trolley is built to perform consistently in demanding industrial environments.

Key Features

Reliable Motorized Drive System

Equipped with industrial-grade electric motors delivering strong traction under heavy loads.

Multiple power options available, including battery power, low-voltage rail supply, or cable reel systems.

Smooth start and stop functions reduce mechanical stress and protect transported steel materials.

Heavy-Duty Steel Structure

Manufactured from thickened high-strength steel plates and reinforced beams.

Designed to withstand concentrated loads, vibration, and harsh operating conditions.

Precision rail wheels ensure stable guidance and accurate movement along tracks.

Flexible Control & Smooth Operation

Operated via wired pendant or wireless remote control.

Variable speed control enables precise positioning and safe handling.

Optional PLC-based automation for synchronized or repetitive transport tasks.

Integrated Safety Protection System

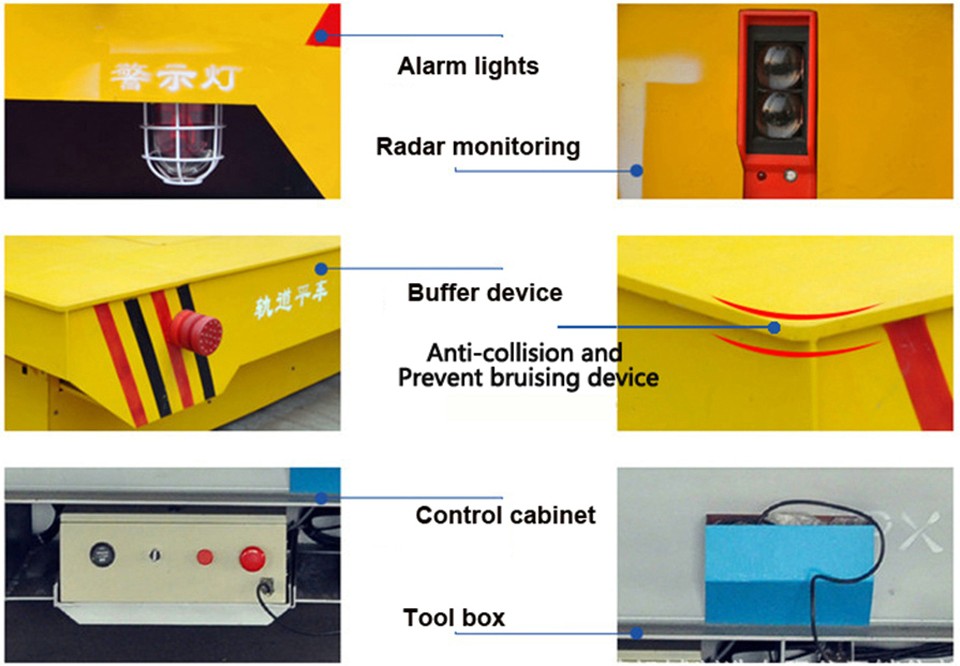

Equipped with emergency stop buttons, overload protection, and audible/visual alarms.

Optional anti-collision sensors, buffer stops, and speed control zones enhance safety.

Designed in accordance with CE and ISO industrial safety standards.

Technical Description

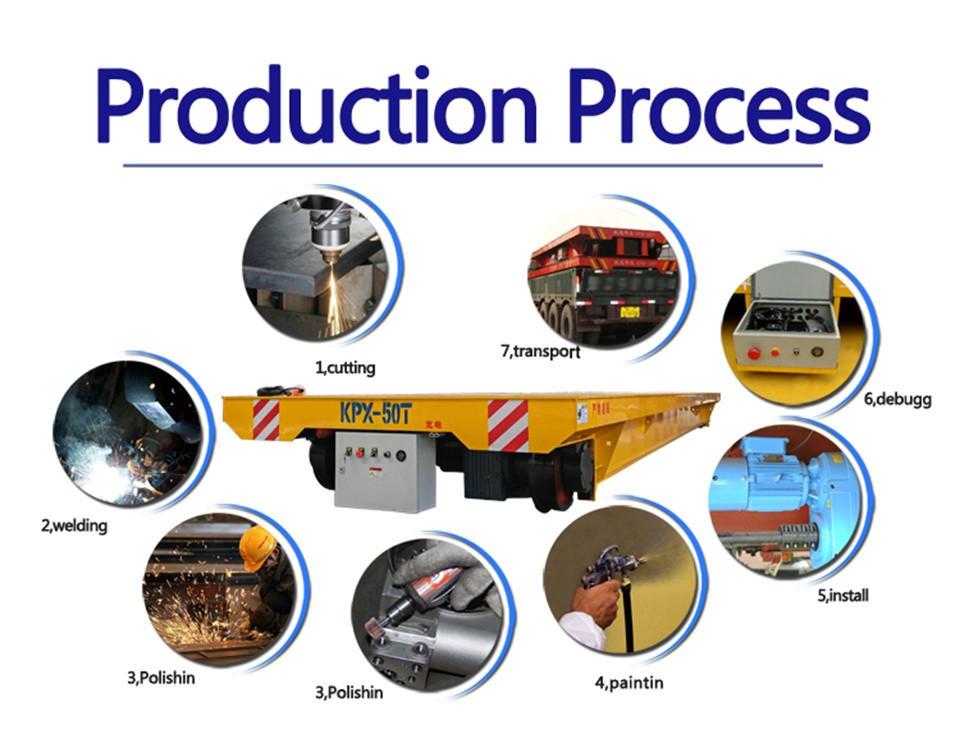

This robust rail transfer trolley operates on heavy-duty steel rails and is driven by an electric motor combined with a high-strength reduction gearbox.

The load capacity can be customized from 5 tons to over 300 tons, depending on steel material handling requirements.

Standard operating speed ranges from 0–20 meters per minute, adjustable to suit different working conditions.

The power system can be configured as battery-driven, rail-powered, or cable-powered, providing flexibility for various plant layouts.

The platform can be customized with flat decks, V-shaped coil supports, side guards, rollers, or heat-resistant surfaces to match different steel material forms.

Typical Applications

Steel Mills & Rolling Plants — Transport of slabs, billets, and steel coils.

Metal Fabrication Workshops — Handling steel plates, frames, and structural components.

Foundries — Movement of heavy cast steel parts and molds.

Heavy Equipment Manufacturing — Internal transport of steel assemblies.

Industrial Warehouses — Rail-based movement of heavy steel inventory.

Advantages

This robust industrial steel material handling rail transfer trolley offers dependable performance for heavy-duty applications.

Its powerful motorized drive system ensures stable and smooth movement even under full load conditions.

The rail-guided design provides excellent stability and precise routing, minimizing the risk of load shifting or operational accidents.

The reinforced steel structure delivers long service life and resistance to harsh industrial environments.

With multiple power supply options and extensive customization capabilities, the trolley can be easily integrated into diverse steel handling processes.

Comprehensive safety features further enhance operational reliability and protect both personnel and materials.