The Rail Guided Material Handling Cart with Lithium Battery Power is a modern and efficient transport solution designed for manufacturing plants, workshops, warehouses, and assembly lines.

By combining rail-guided movement with a high-performance lithium battery system, this cart delivers reliable, flexible, and environmentally friendly material transport without the limitations of cables or external power supplies.

Its compact structure, precise control, and long battery life make it ideal for frequent, medium- to heavy-duty material handling tasks within industrial environments.

Key Features

Advanced Lithium Battery Power System

High-energy-density lithium battery ensures long operating time per charge.

Fast charging capability reduces downtime and increases productivity.

Maintenance-free design with longer service life compared to traditional batteries.

Stable Rail-Guided Operation

Runs on fixed steel rails for predictable and precise travel paths.

Precision rail wheels provide smooth movement and excellent load stability.

Suitable for straight, curved, and multi-station rail layouts.

Efficient Electric Drive System

High-efficiency electric motor with reduction gearbox for strong traction.

Smooth start and stop reduce mechanical shock and protect transported materials.

Adjustable speed for safe and accurate positioning.

Integrated Safety & Control System

Operated via wired pendant or wireless remote control.

Emergency stop, overload protection, and warning alarms included.

Optional anti-collision sensors and automatic braking system.

Technical Description

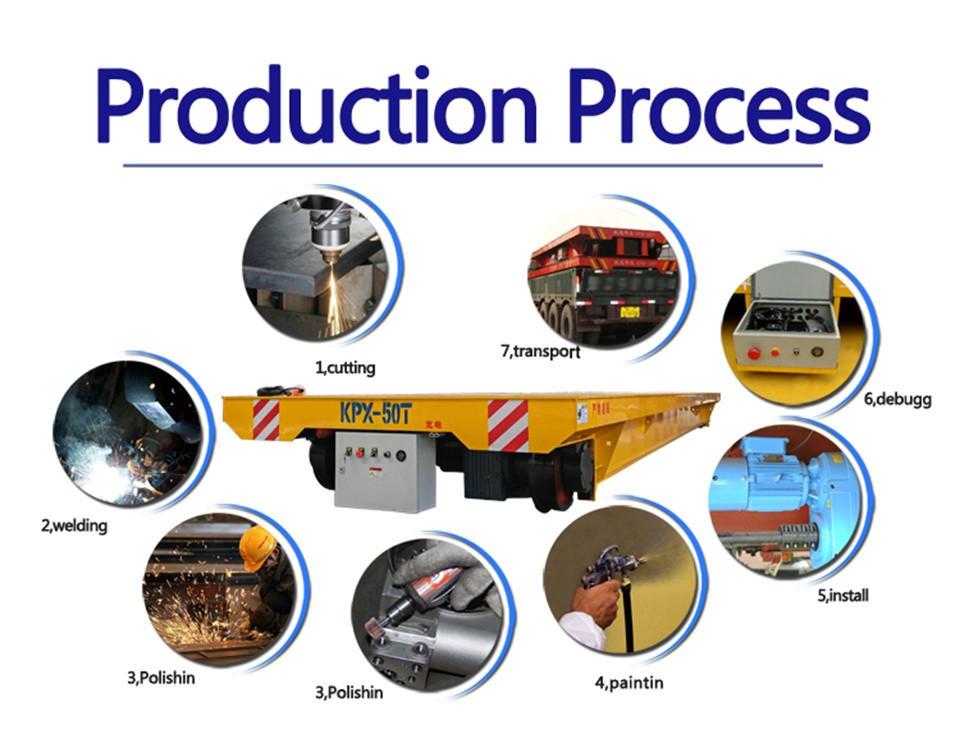

This rail guided material handling cart is powered by an onboard lithium battery and driven by an electric motor through a heavy-duty gearbox.

Load capacity can be customized from 1 ton to over 100 tons, depending on application requirements.

The operating speed is adjustable to match different workflows and safety standards.

The lithium battery system supports multiple working shifts and can be configured with smart battery management (BMS) for enhanced safety and performance.

The platform structure, rail gauge, and wheel configuration can be customized to suit different materials and plant layouts.

Typical Applications

Manufacturing Workshops – Transport of components and sub-assemblies.

Production & Assembly Lines – Movement of materials between stations.

Warehouses & Logistics Centers – Rail-based material distribution.

Tooling & Mold Shops – Safe handling of molds and heavy tooling.