The Precast Concrete Logistics 10 Ton Battery Trackless Transfer Vehicle is a specialized material handling solution designed for the transportation of precast concrete components, molds, pallets, and heavy materials within precast yards and production facilities. With a 10-ton load capacity and battery-powered trackless operation, this vehicle delivers flexible routing, stable performance, and efficient logistics without the need for rails.

Key Advantages

10 Ton Load Capacity: Ideal for precast concrete panels, molds, and components

Battery Powered System: Stable operation with zero emissions and low noise

Trackless Design: Flexible movement across production lines and storage yards

Strong Steel Structure: Designed to withstand heavy loads and harsh environments

High Safety Performance: Suitable for busy precast concrete logistics operations

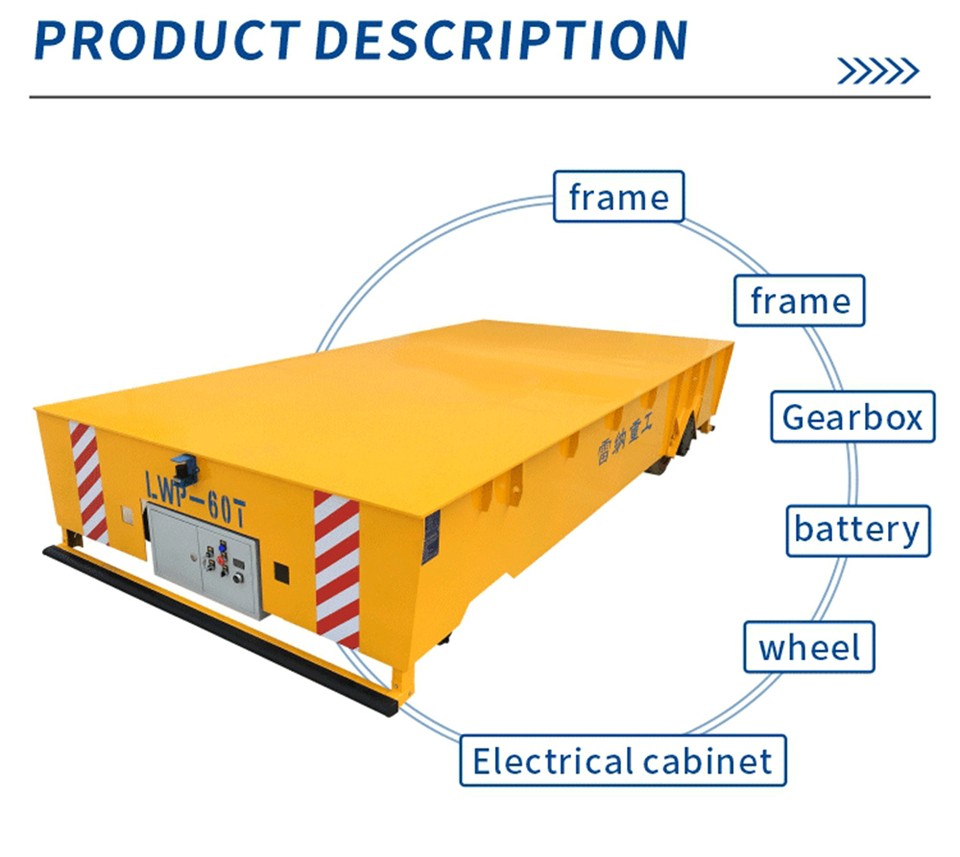

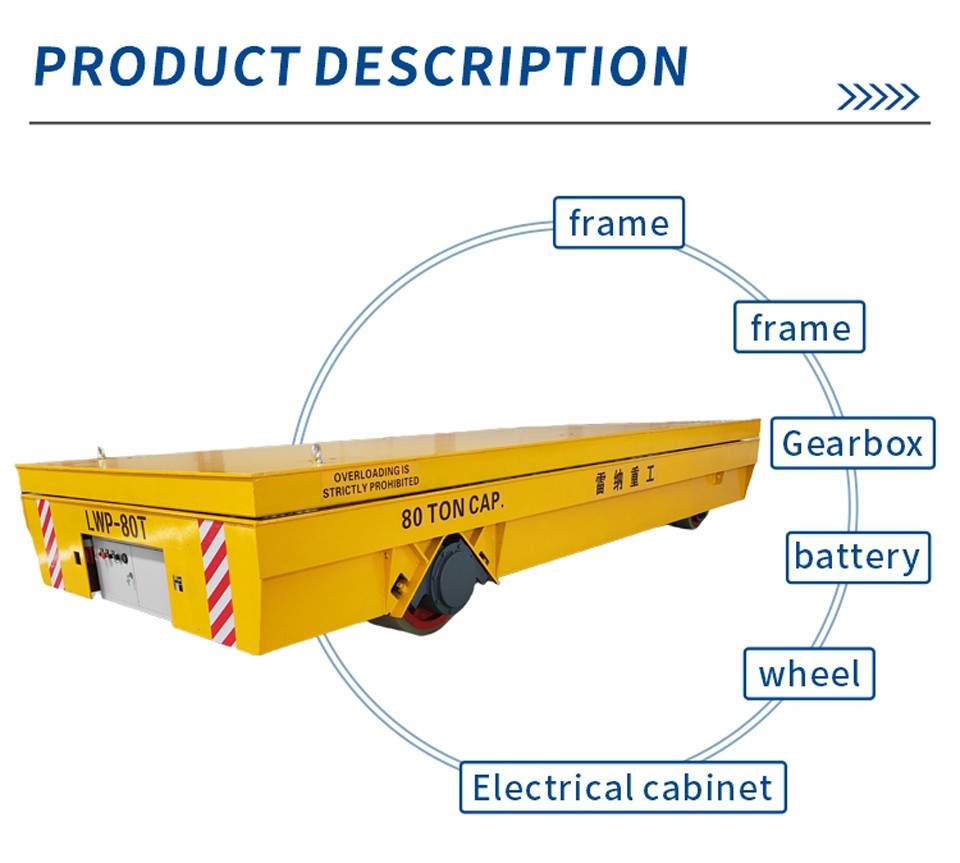

Product Description

The Battery Trackless Transfer Vehicle operates directly on reinforced concrete floors commonly found in precast factories. Without fixed rails, the vehicle can freely travel between casting areas, curing zones, finishing stations, and storage yards, significantly improving logistics efficiency.

Powered by a high-capacity industrial battery, the vehicle ensures reliable torque output under full load. The reinforced platform and heavy-duty wheels are designed to handle the concentrated loads typical of precast concrete products. Integrated safety systems support safe operation in dusty, high-traffic industrial environments.

Main Technical Characteristics

This 10-ton trackless transfer vehicle is engineered for precast concrete logistics. The electric drive system provides smooth acceleration and stable speed control, reducing impact on concrete products during transport. The battery power system supports flexible operation without cable restrictions, making it suitable for dynamic factory layouts. Control options include wireless remote control or operator panel control. The vehicle is designed for flat, reinforced concrete floors and can be customized to meet specific precast production requirements.

Typical Applications

Precast concrete panel and component transport

Mold and pallet handling in precast yards

Material transfer between casting, curing, and storage areas

Internal logistics for precast concrete factories

Heavy product movement in open or semi-open workshops

Customization Options

We offer OEM & ODM customization for precast concrete transfer vehicles:

Platform size and load configuration

Battery capacity and charging method

Drive and steering system layout

Control mode and automation level

Safety features such as alarms, emergency stop, and obstacle detection

Packing & Delivery

Packing: Export-standard packaging with protective wrapping or wooden crate

Delivery Time: 25–40 working days after order confirmation

Shipping Methods: Sea freight, rail transport, or truck delivery

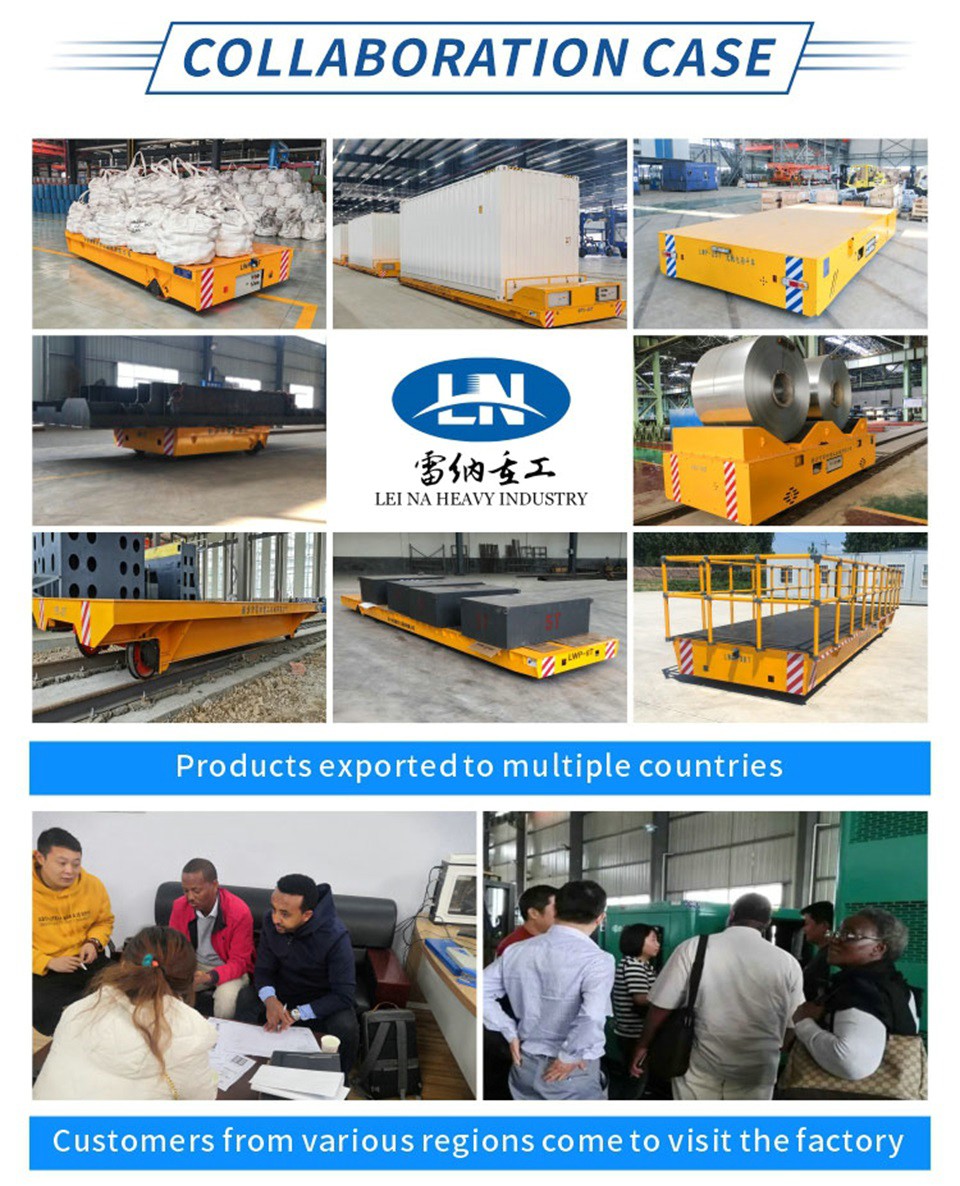

Why Choose Our Precast Concrete Transfer Vehicle

Professional manufacturer of trackless transport equipment for precast industry

Proven performance in heavy-load and dusty environments

Flexible operation with reduced infrastructure investment

Reliable technical support and comprehensive after-sales service

Contact Us Today

For efficient and flexible precast concrete logistics, choose the

Precast Concrete Logistics 10 Ton Battery Trackless Transfer Vehicle.

Send your inquiry now to receive technical details, layout drawings, and a competitive quotation.