The Low Voltage Rail Transfer Trolley is a high-efficiency, rail-guided electric transport vehicle designed for industrial material handling across production lines, workshops, and warehouses.

It operates using a low-voltage power supply system integrated into the rails, providing safe, continuous, and reliable power for long-term use without the need for batteries or cables.

This trolley is ideal for steel mills, machinery plants, automobile manufacturing, and assembly workshops, offering a clean, durable, and cost-effective material transport solution for heavy loads.

Working Principle

The Low Voltage Rail Transfer Trolley draws power directly from the rails, typically at 36V / 48V / 72V AC, using specialized conductive rails and pickup devices (carbon brushes or sliding shoes).

The collected current is converted through an onboard control system and delivered to AC traction motors that drive the trolley along the rails.

This design ensures safe, continuous power transmission with no cable drag or charging downtime, making it ideal for long-distance and high-frequency use.

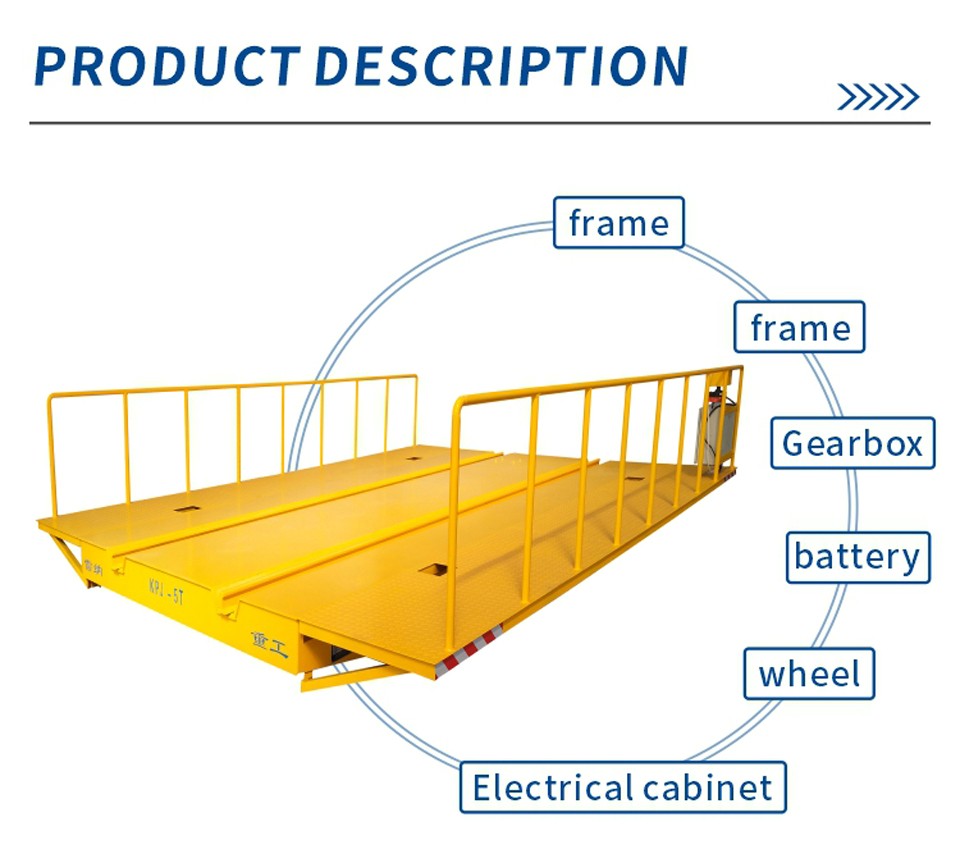

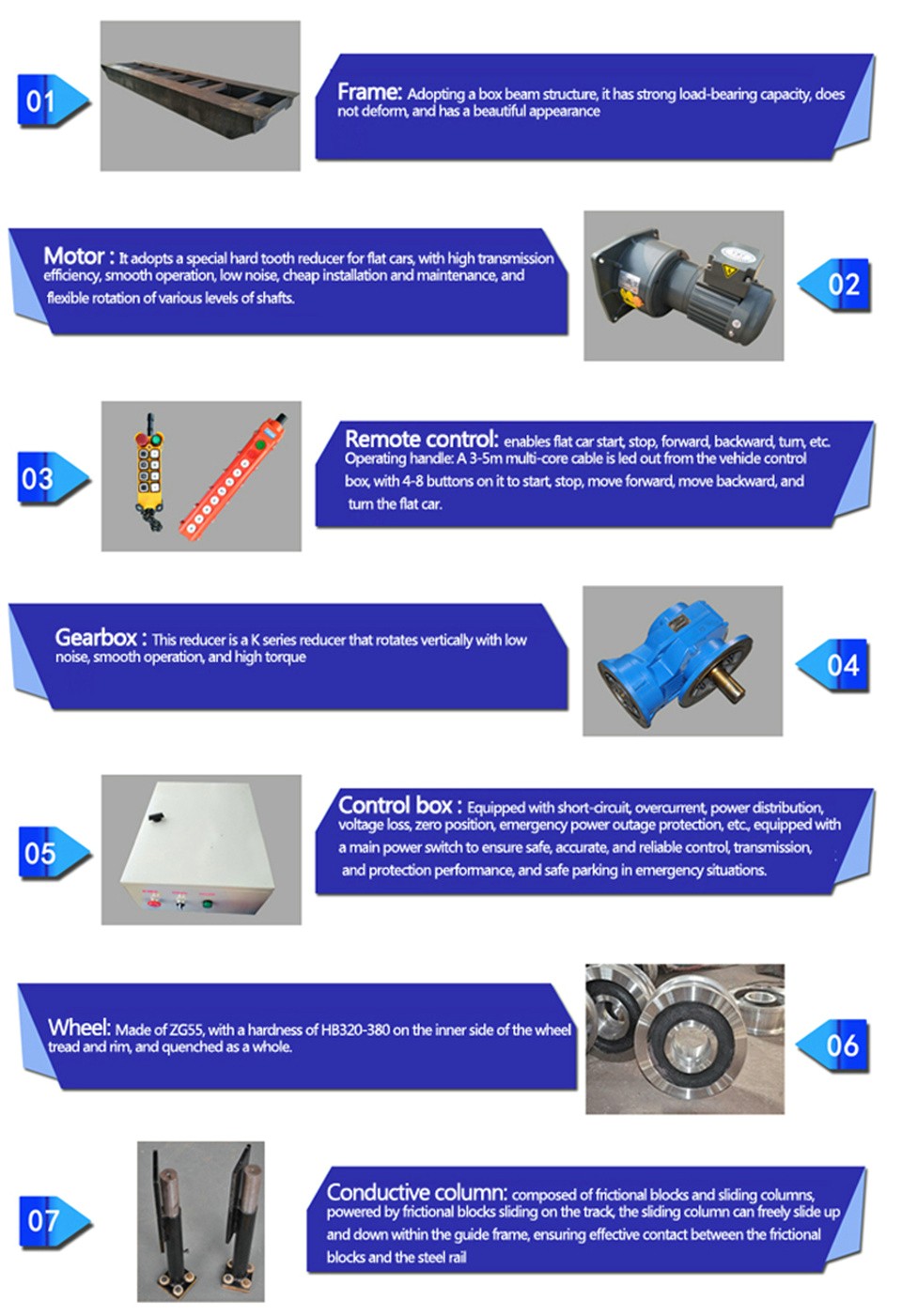

Structural Features

Load Capacity: 1–300 tons (customizable).

Frame Material: Heavy-duty welded steel structure (Q235B or Q345B).

Rail Type: Insulated low-voltage dual-rail system for safe current transfer.

Drive System: Dual-motor AC drive with reduction gearbox.

Wheel Material: Forged steel with precision machining for long service life.

Platform Design: Flat, V-frame, or special fixtures available per application.

Electrical & Control System

Power Supply: Low voltage rail power (36V / 48V / 72V).

Control Mode:

Wired pendant control (standard).

Wireless remote control (optional).

Speed Control: Adjustable via inverter or fixed-speed setup.

Safety Features:

Overcurrent & overload protection.

Limit switches at track endpoints.

Emergency stop and audible alarm.

Optional:

PLC automation with route control.

Positioning sensors for precision transport.

Applications

The Low Voltage Rail Transfer Trolley is suitable for a wide range of industrial material transport scenarios, including:

Steel and Metal Industry: Handling coils, billets, slabs, and castings.

Machinery Manufacturing: Moving machine parts, assemblies, and molds.

Automotive Production Lines: Transporting car bodies, dies, and components.

Warehouse & Logistics Centers: In-plant transport along fixed routes.

Construction & Power Equipment Plants: Handling pipes, cables, and heavy tools.