The Customized Electric Rail Transfer Trolley for Heat Treatment Workshop Use is a specialized industrial transport solution designed for moving heavy components, molds, and raw materials within heat treatment facilities. Built to withstand high-temperature environments, this trolley ensures safe, stable, and efficient material handling in demanding workshops.

Product Highlights

Customized Design: Tailored to fit heat treatment workshop requirements

Electric Powered Drive: Stable, energy-efficient, and easy to operate

Rail-Guided Movement: Accurate positioning along fixed routes

High-Temperature Resistance: Special materials and coatings for heat treatment environments

Heavy Load Capacity: Handles 5–50 tons depending on design specifications

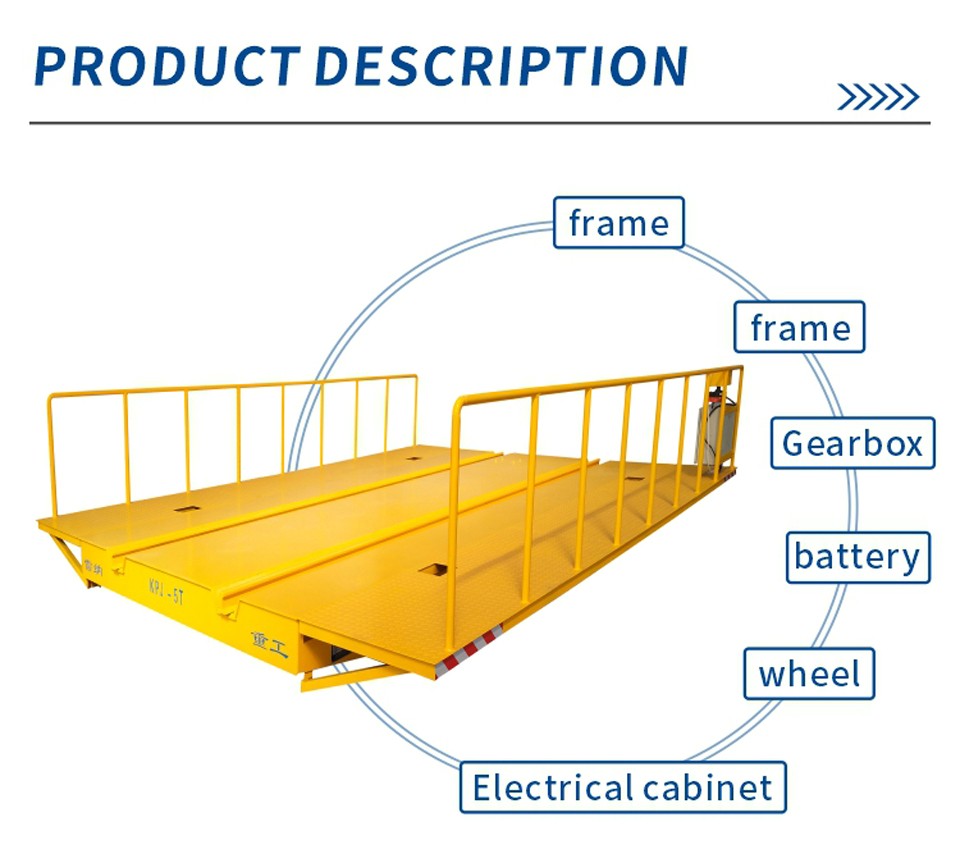

Product Description

The Electric Rail Transfer Trolley is engineered for use in heat treatment workshops, where conventional transport equipment may be affected by high temperatures. Its reinforced steel frame and heat-resistant components allow safe transport of molds, steel parts, and other materials between heating furnaces, cooling stations, and workstations.

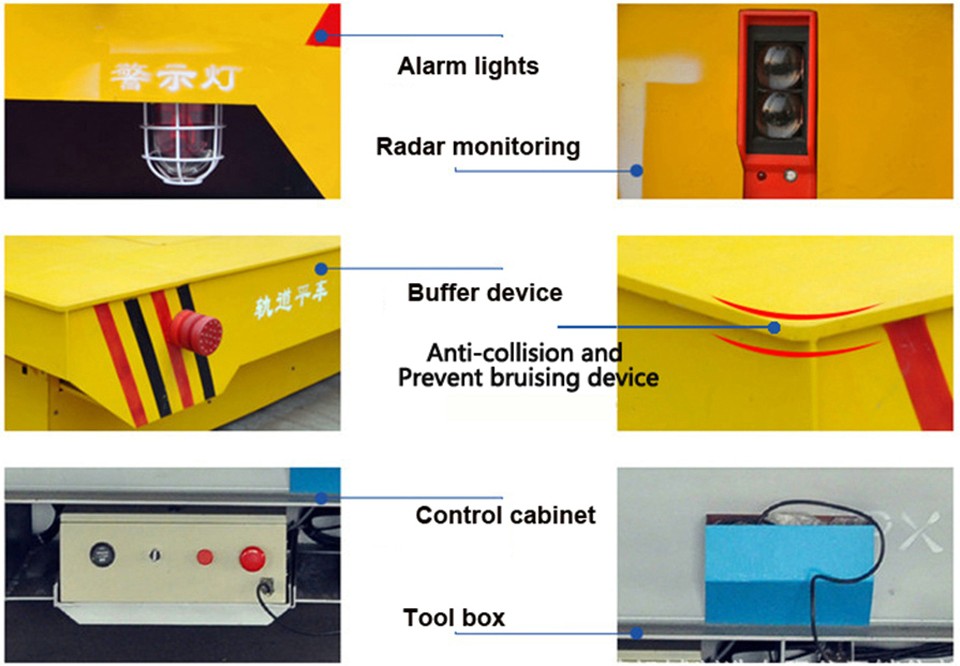

Equipped with an electric drive system, the trolley provides smooth acceleration and deceleration, reducing mechanical wear and protecting the load. Optional features include remote control operation, emergency stop, warning lights, and anti-collision sensors, ensuring operational safety in high-temperature conditions.

Main Specifications

Load Capacity: 5–50 tons (customizable)

Power Supply: Electric drive with rechargeable battery or low-voltage rail power

Control Mode: Push-button pendant, wireless remote control, or PLC automation

Running Speed: Adjustable for workshop workflow

Rail Type: P-type steel rail or square steel rail

High-Temperature Features: Heat-resistant frame, insulated components, special coatings

Safety Devices: Emergency stop button, warning lights, limit switches, anti-collision system

Applications

Heat treatment workshop material transport

Transfer of molds, dies, and heavy components

Movement between heating furnaces and cooling stations

Workshop-to-workshop heavy load transport

Industrial facilities requiring high-temperature handling

Customization Service

We provide OEM & ODM customization for heat treatment workshop trolleys:

Platform size, deck structure, and wheel configuration

Load capacity and rail compatibility

Power system and battery specification

High-temperature resistant materials and coatings

Optional safety features for extreme workshop conditions

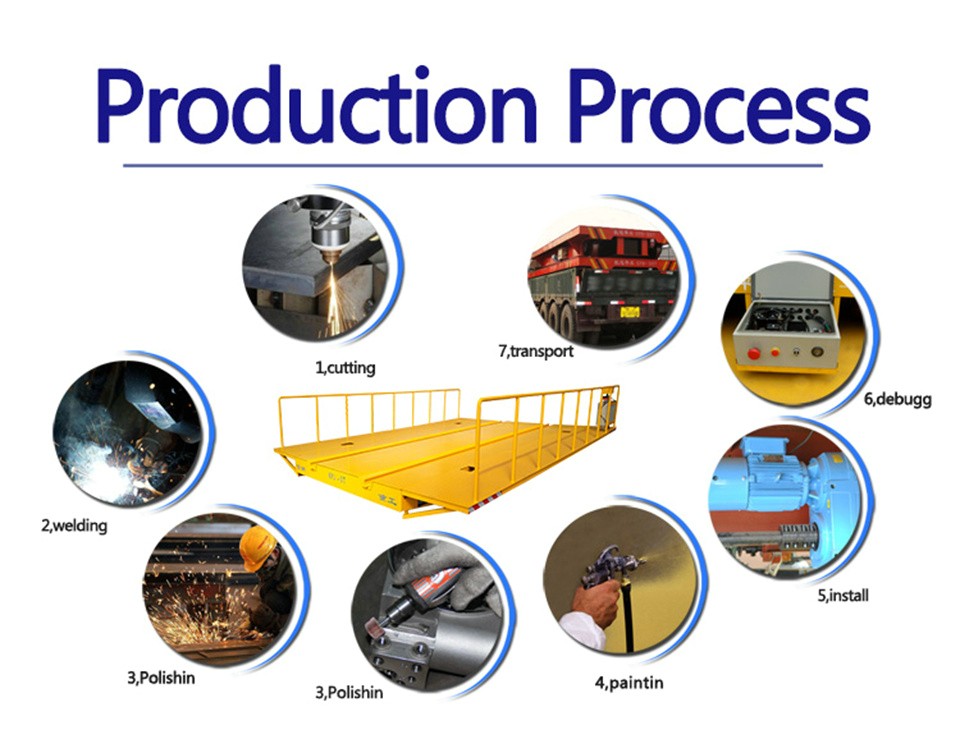

Packing & Delivery

Packing Method: Export standard packing with protective film or wooden crate

Delivery Time: 20–35 working days after order confirmation

Shipping Methods: Sea freight, rail transport, or truck delivery

Why Choose Us

Experienced manufacturer of industrial rail transfer trolleys

Strict quality control and heat-resistant testing

Stable performance and long service life under high-temperature conditions

Reliable technical support and after-sales service

Contact Us Today

For safe, efficient, and high-temperature-capable material transport in your heat treatment workshop, the

Customized Electric Rail Transfer Trolley for Heat Treatment Workshop Use is the ideal solution.

Send your inquiry now to receive technical specifications, drawings, and a competitive quotation.