The 3 Ton Low Voltage Rail Transfer Trolley is a compact, rail-guided electric transport cart designed for safe and efficient material handling in industrial environments.

Powered by a low-voltage rail system, it ensures continuous, cable-free operation, ideal for workshops, assembly lines, and logistics areas that require frequent, repetitive transport tasks.

This model offers high reliability, low maintenance, and smooth performance, making it an excellent choice for small to medium load transport within manufacturing plants and warehouses.

Working Principle

The trolley receives power directly from the rails, which are supplied with 36V / 48V / 72V low-voltage electricity through a transformer system.

A current pickup device (carbon brush or sliding contact shoe) collects the power and feeds it to the AC traction motors, which drive the trolley’s wheels.

This configuration eliminates the need for batteries or cable reels, ensuring safe, uninterrupted power for continuous use.

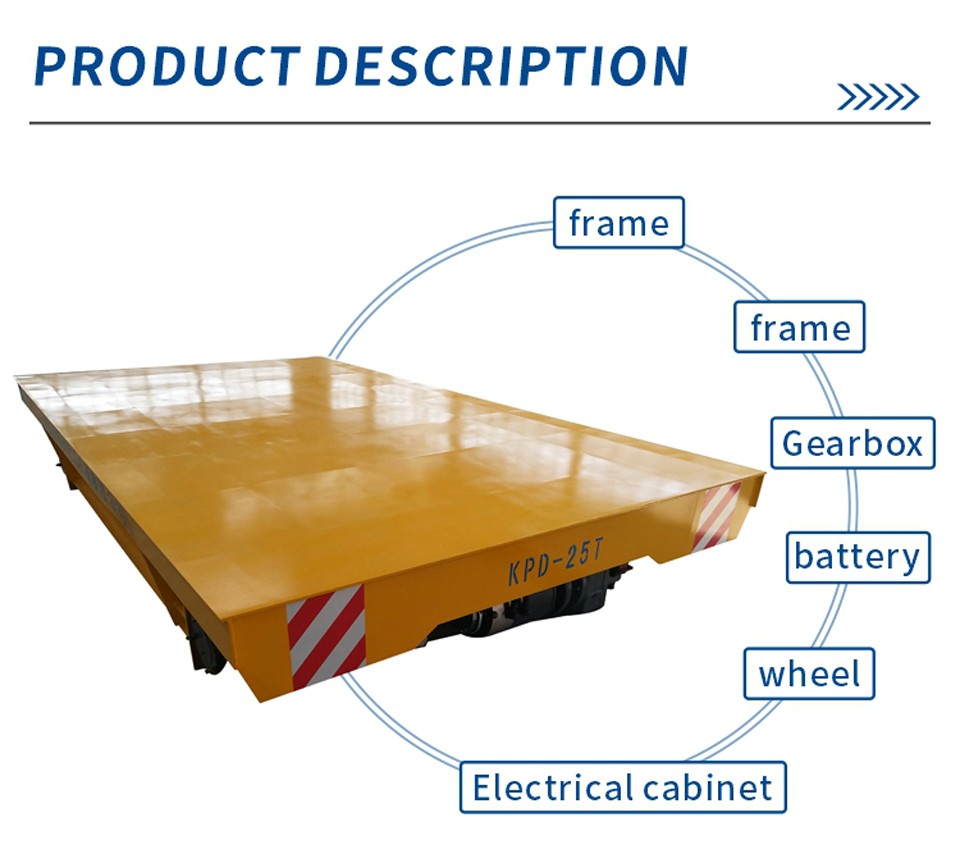

Structural Features

Load Capacity: 3 tons (customizable from 1–300 tons).

Platform Size: 2500 × 1500 mm (customizable).

Frame Material: High-strength welded steel (Q235B or Q345B).

Rail System: Dual insulated rails for safe low-voltage power supply.

Drive System: Dual-motor AC drive with reducer for stable traction.

Wheel Material: Forged steel with precision machining and wear resistance.

Platform Type: Flat deck or optional fixture (V-frame, support posts, etc.).

Electrical & Control System

Power Supply: Low-voltage rail system (36V / 48V / 72V).

Control Mode:

Wired pendant control (standard).

Wireless remote control (optional).

Speed Control: Fixed or adjustable via frequency converter (VFD).

Safety Features:

Overload and overcurrent protection.

Limit switches and emergency stop.

Acoustic and visual warning devices.

Optional:

PLC automatic operation and route programming.

Positioning sensors for accurate stopping.

Applications

The 3 Ton Low Voltage Rail Transfer Trolley is designed for industrial material transport in:

Machinery manufacturing workshops

Steel and metal processing plants

Automotive and mold production lines

Warehouse and assembly areas

Production workshops requiring safe, repetitive transport

Typical materials include small molds, components, tools, coils, and assembly parts.