The Industrial Electric Cart for Transporting Die Casting Molds is a specialized heavy-duty material handling solution designed for die casting factories, automotive component plants, and precision mold manufacturing workshops.

Built to deliver safe, stable, and efficient mold transfer, this electric cart ensures smooth operation during mold installation, removal, repair, and production line changeovers.

Equipped with a durable electric drive system, reinforced chassis, and intelligent control, it significantly improves workflow efficiency and reduces manual labor risks.

Key Features

High-Performance Electric Drive System

Provides powerful traction for transporting medium to heavy die-casting molds.

Supports continuous operation with low noise and smooth acceleration.

Optional battery power or cable power depending on workshop layout.

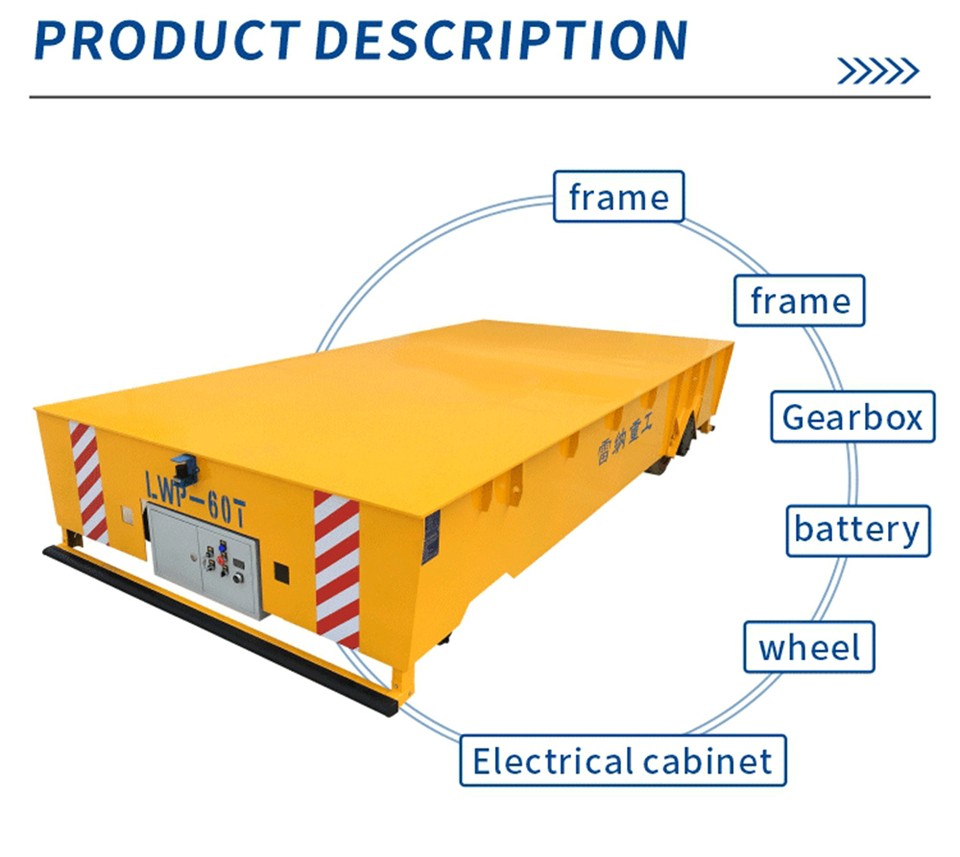

Reinforced Mold Transport Platform

Heavy-duty frame engineered to withstand the concentrated load of large molds.

Ultra-stable platform ensures safe handling during transport and positioning.

Customizable with anti-slip plates, guide rails, or mounting holes.

Flexible Steering & Smooth Maneuvering

Supports straight, reverse, and precision slow-speed movement.

Optional steering modes:

✓ Single-direction drive

✓ Dual-drive steering

✓ Omnidirectional steering (trackless type)Ideal for narrow aisles and precision positioning next to molding machines.

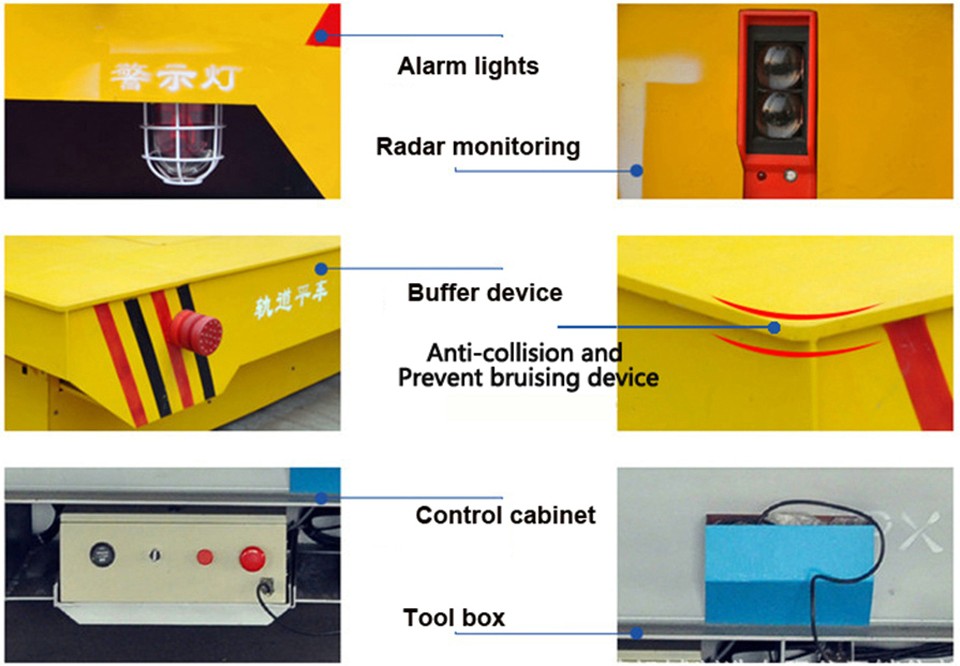

Smart and Easy Control

Operated via wireless remote or wired pendant.

Variable speed function protects molds and improves accuracy.

Optional upgrades:

– PLC automation

– Positioning sensors

– Safety distance detection

Safety & Protection System

Emergency stop, overload protection, and audible/visual alarms.

Shock-absorbing design minimizes vibration during mold transport.

Compliant with CE and ISO industrial safety standards.

Technical Description

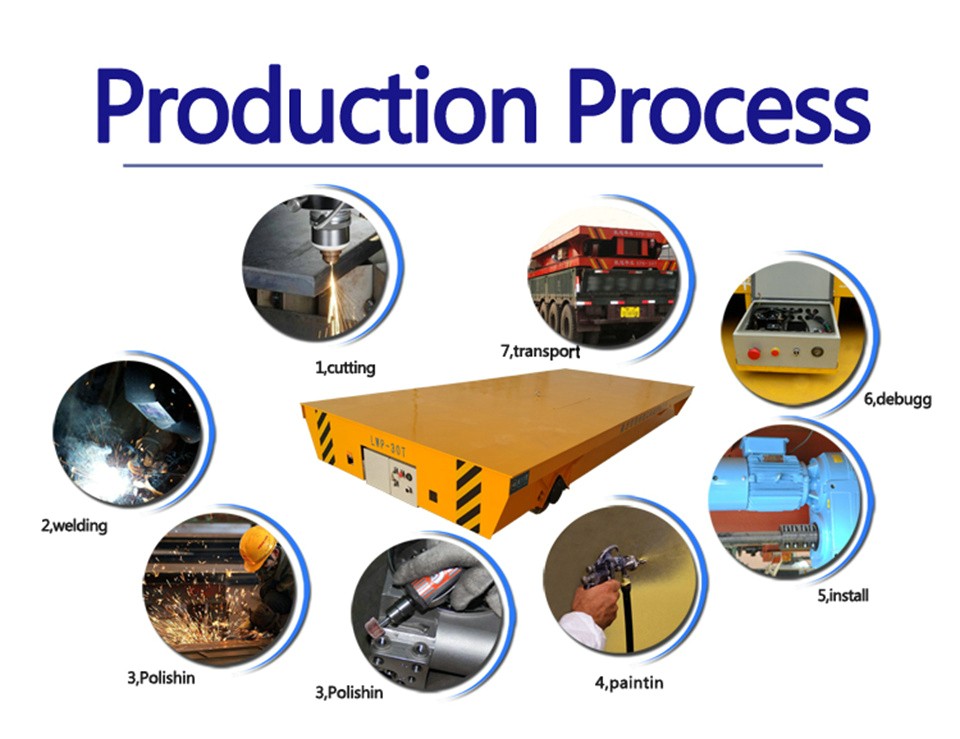

This industrial electric mold transport cart uses a high-efficiency motor system to drive the platform with precise speed control. Its load-bearing structure is manufactured from high-strength welded steel, ensuring stability under heavy concentrated loads typical of die-casting molds.

The operational speed can be adjusted between 0–20 m/min, suitable for controlled handling near machines.

Power can be supplied through battery packs or cable reels, depending on customer needs.

The cart can be customized with hydraulic lifting, tilting mechanisms, mold alignment fixtures, or safety guards to meet specific process requirements.

Typical Applications

Die Casting Workshops — Transport of molds to casting machines.

Automotive Parts Production — Handling heavy aluminum or magnesium molds.

Mold Repair & Maintenance Areas — Moving molds between workstations.

Tooling Warehouses — Efficient storage and transfer of various die sets.