The Electric Flexible Steering Trolley for Mold Transport is a high-performance material handling vehicle designed specifically for the safe, efficient, and precise movement of heavy molds within factories and workshops.

Equipped with an advanced electric drive system and flexible steering mechanism, this trolley provides excellent maneuverability, making it ideal for navigating tight aisles, curved paths, and complex production layouts.

It offers a stable flatbed platform, smooth speed control, and greater operational flexibility compared to conventional forklifts or rail-guided carts.

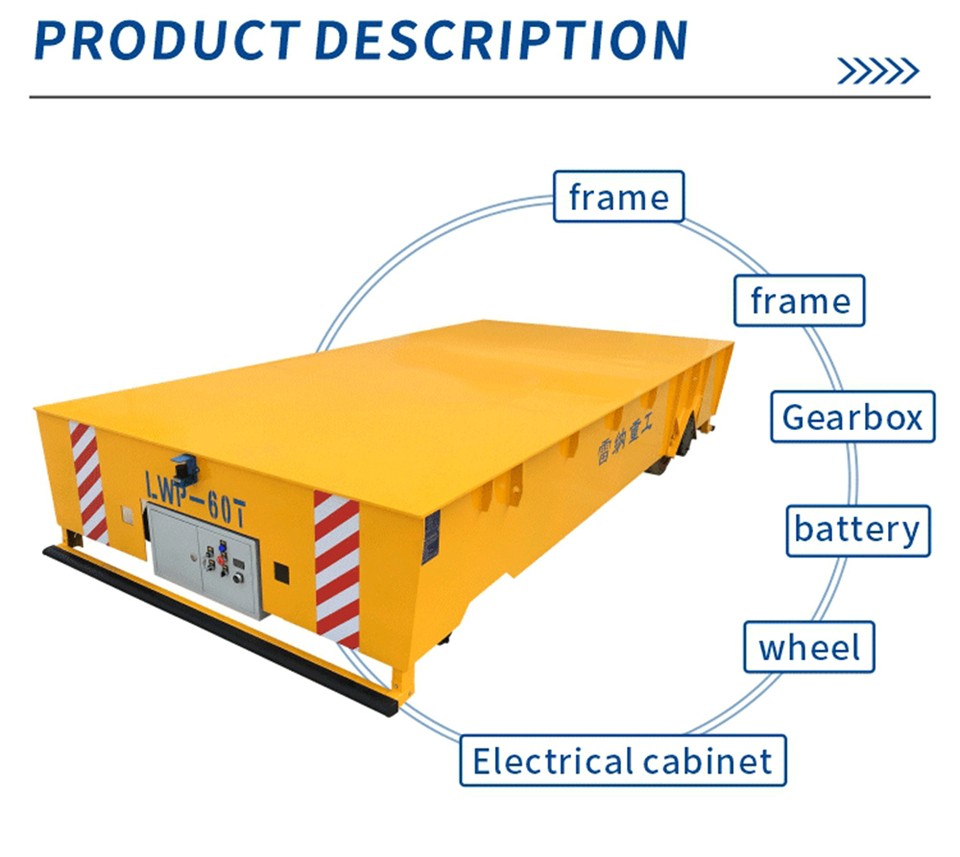

Product Overview

This electric mold transfer trolley is powered by a high-capacity industrial battery, ensuring wireless operation and enabling free movement across different workshop areas.

Its flexible steering system—available in front-wheel steering, differential steering, or omnidirectional (360°)—allows operators to handle molds accurately and safely, significantly improving overall production efficiency.

The trolley is commonly used in mold workshops, automotive stamping lines, injection molding plants, and other heavy tooling environments.

Main Features

High Load Capacity: Typically 5–50 tons (customizable for heavier molds).

Power Supply: Maintenance-free battery or lithium battery pack.

Steering Options:

Standard steering

Differential steering

Omnidirectional Mecanum steering (optional)

Platform Type: Flat, V-frame, non-slip surface, or custom clamps for mold fixation.

Drive System: Dual electric motors with smooth acceleration.

Control Mode: Wireless remote + onboard control panel.

Safety Devices: Emergency stop, audible alarm, strobe light, anti-collision sensors.

Advantages

Flexible Steering for Tight Spaces

Operates easily in confined areas and narrow aisles.

Precise maneuvering reduces risk during mold positioning.

Safe and Stable Mold Handling

Designed to support high center-of-gravity loads securely.

Optional mold locking, guiding rails, or stoppers available.

Efficient Electric Drive System

Zero-emission, low-noise operation.

Long battery life ensures continuous shift performance.

Customizable Platform & Structure

Tailored to mold sizes, shapes, and production workflow requirements.

Options for hydraulic lifting, tilting, or rotating tables.

User-Friendly Operation

Remote control with adjustable speed.

Smooth start/stop system enhances safety for precision mold alignment.

Typical Applications

Injection mold transportation

Press molds for automotive manufacturing

Die casting mold handling

Heavy tooling and fixture movement

Assembly line mold loading/unloading