The factory-customized battery-powered rail transfer vehicle is an intelligent handling device designed specifically for material transport on factory floors. Powered by a built-in high-performance battery, it eliminates the constraints of traditional busbars or cable reels on factory layouts.

This device operates smoothly along pre-set tracks and features strong load-bearing capacity, stable operation, safety, environmental friendliness, and flexible layout. It is widely applicable in production workshops, assembly lines, warehouses, and logistics centers, enabling efficient transfer of raw materials, semi-finished products, and finished products between processes.

The customized design meets the individual needs of different factories for equipment structure, functionality, and control systems, helping companies upgrade to automated logistics.

Core Values and Advantages

Battery-Powered, Flexible and Efficient

It eliminates the constraints of fixed power sources and is suitable for production workshops with complex layouts or large areas.

It offers 6-8 hours of continuous operation on a single battery charge, and supports quick replacement of backup batteries.

The elimination of high-voltage cables reduces safety hazards and reduces factory renovation costs.

Strong Load Capacity and Wide Application Range

The load capacity range is 1 to 50 tons, meeting transport needs from small parts to large equipment or raw materials.

The frame is made of high-strength welded steel, resistant to impact and deformation.

Safety and Environmental Protection

Battery-powered, zero-emission, and low-noise, meeting green factory construction requirements.

Equipped with multiple safety systems including audible and visual alarms, emergency brakes, and limit switches.

Soft start and stop functions protect materials and equipment.

Flexible Control

Control Options:

Handle-controlled for close-range operation;

Wireless remote control for single-person remote control;

PLC automatic control for unmanned operation;

Supports integration with factory production management systems (MES/WMS) for intelligent scheduling.

Customizable Design

Customize the structure, size, functionality, battery type, and other aspects to meet specific production needs.

The tabletop can be configured with a flat plate, V-shaped bracket, roller conveyor, or hydraulic lift to meet diverse process requirements.

Structural Components

The factory-customized battery-powered rail transfer vehicle consists of the following components:

Carriage Structure

High-strength welded steel frame structure, providing strong load-bearing and impact resistance.

Surface treatment with sandblasting and anti-corrosion coating provides wear and rust resistance, suitable for long-term use in industrial environments.

Power System

Powered by high-capacity industrial batteries, available in lead-acid or lithium batteries.

Battery packs can be quickly replaced or centrally charged to ensure continuous operation.

Drive and Braking

Employing a high-efficiency DC motor for smooth and quiet operation.

Equipped with a dual electromagnetic and mechanical braking system for safe stopping.

Control System

Equipped with stepless speed regulation, the vehicle can adjust operating speed according to actual needs.

Supports wireless remote control, handle operation, and automated control interfaces.

Track System

Compatible with P18-P50 standard tracks.

Track gauge can be customized to meet site requirements, adapting to various production layouts.

Technical Parameters

This rail transfer vehicle has a rated load capacity range from 1 ton to 50 tons, with common sizes including 5, 10, and 20 tons.

Powered by high-performance industrial batteries, the device provides 6-8 hours of continuous operation on a single charge. The battery capacity can be customized to suit the production line's operating cycle.

The operating speed is adjustable from 0 to 20 meters per minute, with soft start and stop functions to ensure smooth transportation.

Control options include joystick remote control, wireless remote control, or PLC automation, meeting different levels of automation requirements.

The device's platform size, track gauge, and functional modules can be flexibly customized based on the specific materials being transported and the process flow.

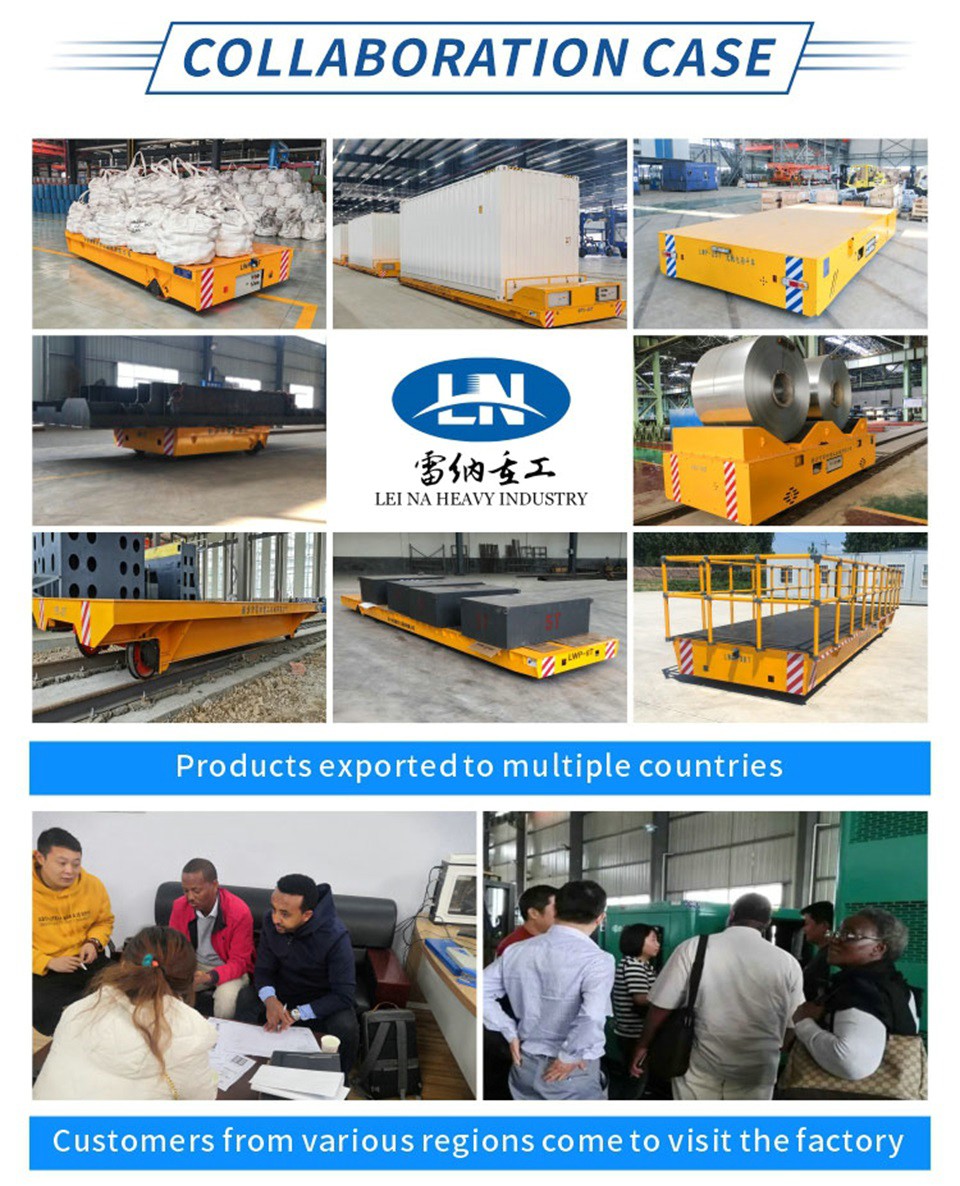

Applications

Intra-production material transportation

Raw material loading and transportation to the production line;

Transfer of semi-finished products between processes;

Transport of large equipment or workpieces;

Scheduling and handling of large components or equipment in the machinery manufacturing industry;

Handling of heavy steel coils, castings, or furnace charges in the metallurgical industry.

Mold and fixture handling

Mold loading and unloading in the mold workshop, and connection between the mold warehouse and production line.

Warehousing and logistics center

Bulk transportation of pallets, boxes, or pallets;

Seamless integration with automated warehouses.

Electronics manufacturing and precision machining

Transport of precision parts or consumable parts, ensuring safe and stable transportation.