The electric rail transfer vehicle for manufacturing workshops is a specialized industrial material handling device designed for internal transportation within production workshops, manufacturing plants, and warehouse logistics systems.

This device operates on pre-laid steel rails and is powered by batteries or an external power source. It enables efficient and safe transfer of raw materials, semi-finished products, jigs and fixtures, large equipment, or finished products between various process steps.

Compared to traditional manual carts or forklifts, it offers advantages such as high automation, improved transport efficiency, superior safety, and stable operation. It has become a core component of modern smart factory material handling systems.

Key Features

1. Electric Drive, Green and Energy-Saving

Powered by batteries or busbars, it is energy-efficient, environmentally friendly, and has zero emissions.

It can operate continuously for 6-8 hours on a single charge, allowing for quick replacement of backup batteries.

It eliminates the need for high-voltage cables, reducing safety hazards and lowering energy costs.

2. Track-Based Operation, Strong Load Capacity

Runs along factory-installed steel rails for precise positioning and smooth operation.

Wide load range, customizable from 1 to 100 tons.

Frame welded from high-strength steel, sturdy structure, impact-resistant, and deformation-resistant.

3. Multiple Safety Features

Equipped with safety devices such as audible and visual alarms, limit switches, and an emergency stop button.

Soft start and stop design effectively protects materials and equipment.

Expandable intelligent protection systems such as laser obstacle avoidance and infrared sensing.

4. Intelligent Control, Convenient Operation

Flexible control options available:

Handle-controlled remote control: Suitable for short-distance, simple operation.

Wireless remote control: Single-person remote control for enhanced safety.

PLC automation control: Seamlessly integrates with production lines and warehouse systems, enabling unmanned transportation.

Supports stepless speed regulation, allowing for flexible adjustment based on site needs.

5. Multifunctional Expansion to Meet Different Needs

Adjustable expansion modules such as V-shaped brackets, roller conveyors, and hydraulic lifts can be added.

Can be integrated with automated warehouses, robots, AGVs, and other systems to form an intelligent handling system.

The platform size, track gauge, and battery type can be customized according to customer needs.

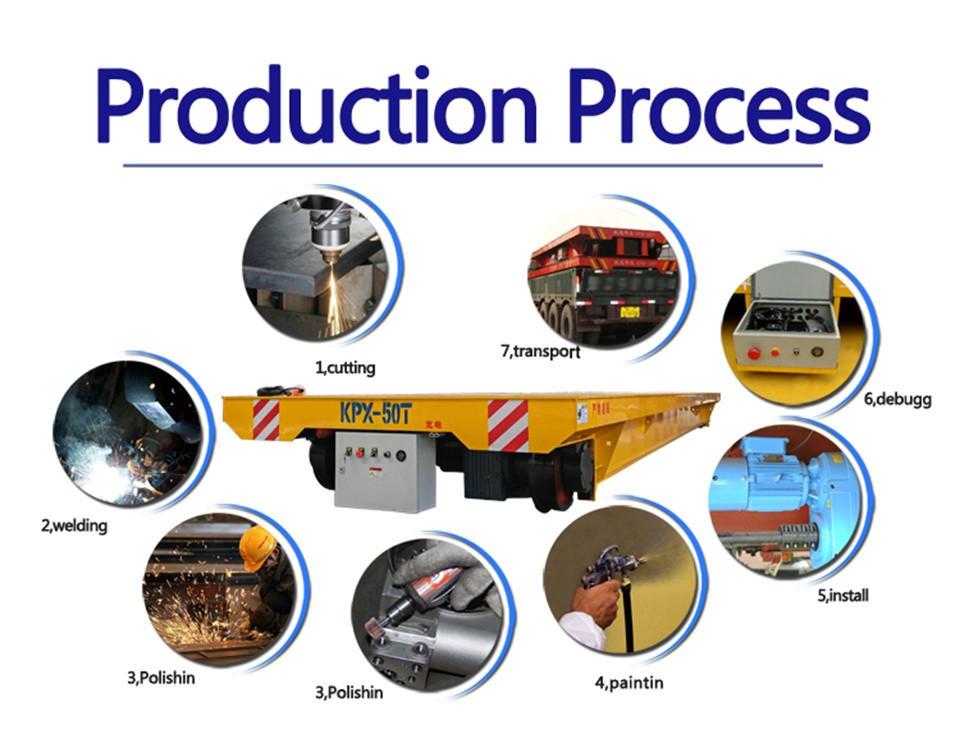

Structural Components

The electric rail transfer vehicle for manufacturing workshops consists of the following core modules:

The vehicle structure is welded from high-strength steel for impact resistance, with a customizable platform. The surface is sprayed with an anti-corrosion coating to adapt to industrial environments.

Power System: Powered by batteries or busbars, it offers strong power and supports long-term continuous operation.

Drive System: Driven by a DC motor for smooth and low noise operation, with stepless speed control.

Braking System: Equipped with electromagnetic and mechanical brakes to ensure safe and reliable parking.

Control System: Multiple operation modes: joystick, wireless remote control, and PLC automatic control, providing a high level of intelligence.

Safety System: Audible and visual alarms, emergency stop button, limit switches, and optional laser or infrared obstacle avoidance. The track system is compatible with P18-P50 track specifications and can be customized to suit the factory layout.

Technical Parameters

Rated load range: 1 ton – 100 tons (common models: 5 tons, 10 tons, 20 tons, and 30 tons)

Power supply: Industrial battery / conductor bar / cable reel

Battery life: 6-8 hours of continuous operation on a single charge

Speed: 0 – 20 m/min, adjustable

Steering: Straight travel, optional automatic steering

Control mode: Handle operation / wireless remote control / PLC automatic control

Safety features: Emergency stop, limit switch, audible and visual alarm, slow start and slow stop

Track gauge: Customized according to factory design, generally 1200mm – 2000mm

Applicable environment: -20°C to +50°C, dust and moisture-proof design optional

Customization: Table shape, size, battery capacity, and control system can all be customized

Application scenarios

1. Material Transportation in Production Workshops

Transporting raw materials from the warehouse to the production line;

Transferring semi-finished products between processes to improve production line efficiency.

2. Handling of Large Equipment and Heavy Workpieces

Managing large workpieces or equipment in the machinery manufacturing, automotive manufacturing, and heavy equipment industries;

Transporting steel coils, castings, or furnace charges in the metallurgical industry.

3. Mold Handling and Assembly Workshops

Moving molds onto and off the production line in the mold workshop;

Transporting tooling and fixtures for precise docking with production equipment.

4. Intelligent Warehousing and Logistics Centers

Transporting batches of finished products or pallets;

Can be used in conjunction with high-bay warehouses and intelligent sorting systems.