The Heavy Duty Customized 30 Ton Omnidirectional Transfer Vehicle is a high-performance material handling solution designed for safe, flexible, and precise transport of heavy industrial loads in complex workshop environments.

With a rated capacity of 30 tons, this vehicle is ideal for mold handling, die transport, steel component movement, and large equipment positioning where conventional rail or single-direction carts are insufficient.

Its omnidirectional movement capability allows forward, backward, lateral, diagonal travel, and in-place rotation, enabling accurate positioning in confined spaces and significantly improving internal logistics efficiency.

Key Features

True Omnidirectional Drive System

360° movement including sideways and diagonal travel.

Zero-radius turning for precise alignment and positioning.

Ideal for narrow aisles and congested workshop layouts.

30 Ton Heavy-Duty Load Design

Reinforced steel chassis engineered for high concentrated loads.

Optimized wheel and drive structure ensure stability under full load.

Designed for long-term industrial use in demanding conditions.

Electric Power & Drive System

High-capacity industrial battery for cable-free operation.

High-torque motors deliver smooth acceleration and controlled braking.

Energy-efficient design supports extended operating cycles.

Flexible Control Options

Wireless remote control for safe operation at a distance.

Optional wired pendant or PLC-based control system.

Proportional speed control for precise positioning tasks.

Comprehensive Safety Configuration

Emergency stop buttons and overload protection system.

Audible and visual alarms during movement.

Optional laser scanners, anti-collision sensors, and speed limit zones.

Technical Description

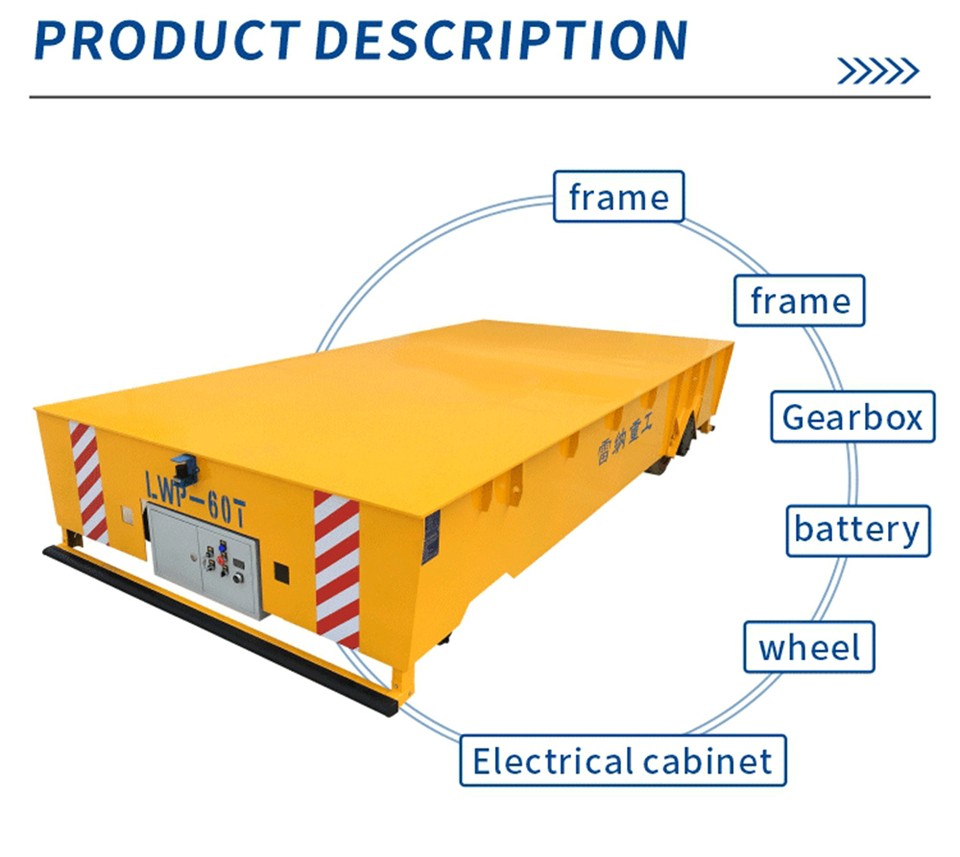

This omnidirectional transfer vehicle is powered by an electric drive system integrated with multi-directional wheel assemblies.

The rated load capacity is 30 tons, with structural safety factors suitable for heavy industrial applications.

Travel speed is adjustable to meet both transport and positioning requirements.

The platform size, wheel type, battery capacity, and control system can be fully customized according to customer workflow and load characteristics.

Optional features such as lifting mechanisms, roller decks, V-blocks, or mold fixtures can be integrated for specialized handling needs.

Typical Applications

Mold & Die Workshops – Transport and positioning of heavy molds.

Die Casting & Stamping Plants – Handling of large dies and tooling.

Heavy Manufacturing Facilities – Movement of oversized components.

Automotive & Equipment Plants – Flexible internal logistics solutions.

Advantages

This heavy duty 30 ton omnidirectional transfer vehicle provides exceptional flexibility for complex industrial environments.

The 360° movement capability eliminates the need for fixed rails and large turning spaces.

Its robust structural design ensures safe and stable handling of heavy loads.

Precise remote control allows accurate positioning, reducing handling time and risk of damage.

Full customization options make the vehicle adaptable to a wide range of applications and production layouts.