The Electric Multi-Directional Mold Transport Solution – 30 Ton is a high-performance material handling system developed for safe, flexible, and precise transportation of heavy molds and dies within industrial workshops.

With a rated load capacity of 30 tons, this transport solution is ideal for injection molding plants, die-casting workshops, stamping lines, and tooling centers where space is limited and maneuverability is critical.

Featuring multi-directional (omnidirectional) movement, the vehicle can travel forward, backward, sideways, diagonally, and rotate in place, allowing accurate positioning of large molds without complex turning radii.

Key Features

Multi-Directional / Omnidirectional Drive System

Enables 360° movement including lateral and diagonal travel.

Allows in-place rotation for precise mold alignment.

Ideal for confined workshop spaces and complex layouts.

30 Ton Heavy-Duty Load Capacity

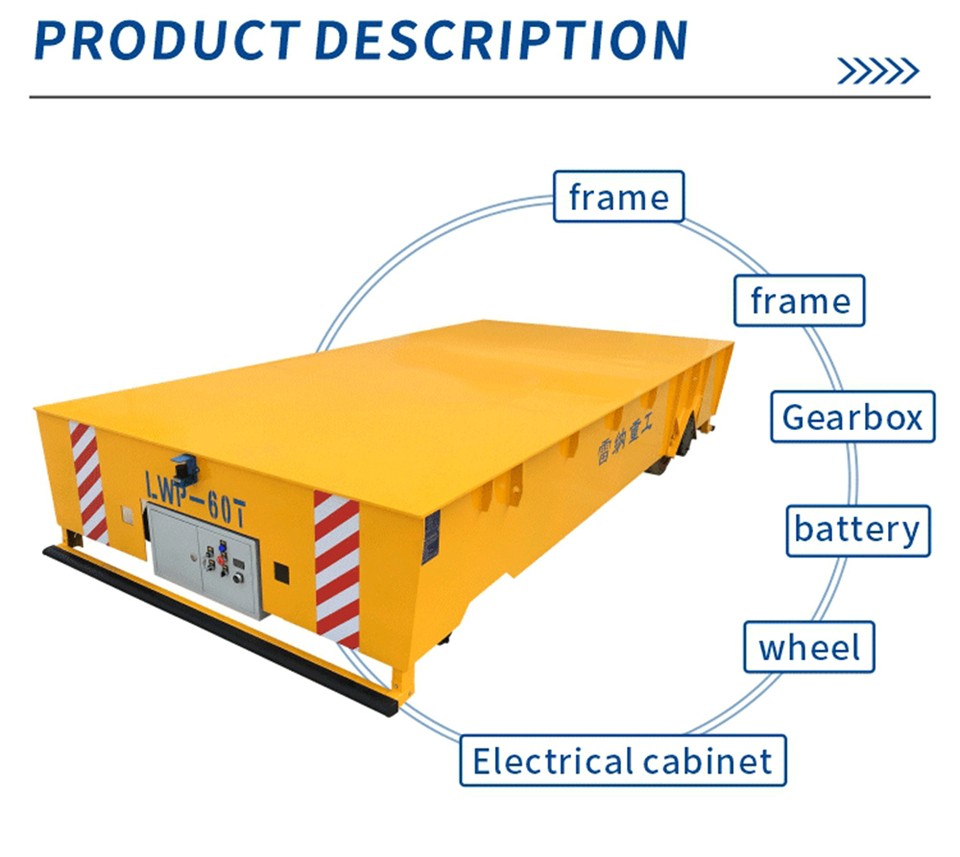

Reinforced steel chassis designed for high concentrated mold loads.

Excellent structural rigidity ensures stability during transport and positioning.

Suitable for large and oversized molds and dies.

Electric Power System

Powered by industrial-grade battery system for cable-free operation.

Smooth acceleration and deceleration protect molds from impact.

Supports continuous workshop operation with reliable power output.

Precise & Easy Control

Operated via wireless remote control or wired pendant.

Proportional control enables millimeter-level positioning accuracy.

Optional PLC system for semi-automatic or automated transport tasks.

Advanced Safety Configuration

Emergency stop system and overload protection.

Audible and visual warning alarms during operation.

Optional laser scanners, anti-collision sensors, and speed limit zones.

Technical Description

This electric multi-directional mold transport vehicle is driven by a high-torque electric motor system integrated with omnidirectional wheels.

The rated load capacity is 30 tons, designed with industrial safety margins for heavy mold handling.

Travel speed is adjustable to balance efficiency and safety, especially during precise positioning near molding machines.

The platform size, wheel configuration, and load supports can be customized to suit specific mold dimensions.

Optional lifting systems, roller decks, or hydraulic positioning devices can be integrated for seamless mold loading and unloading.

Typical Applications

Injection Mold Workshops – Transport and positioning of large molds.

Die Casting Plants – Safe movement of heavy dies between machines.

Stamping & Press Lines – Handling of press molds and tooling.

Automotive Tooling Centers – Internal logistics of large and complex molds.

Advantages

This 30 ton electric multi-directional mold transport solution significantly improves mold handling efficiency in modern workshops.

The omnidirectional movement capability eliminates the need for fixed rails and wide turning spaces.

Its high load-bearing structure ensures stable and secure transport of heavy molds.

The precise control system allows accurate alignment with machines, reducing setup time and risk of damage.

Battery-powered operation and comprehensive safety features enhance flexibility, safety, and overall productivity.