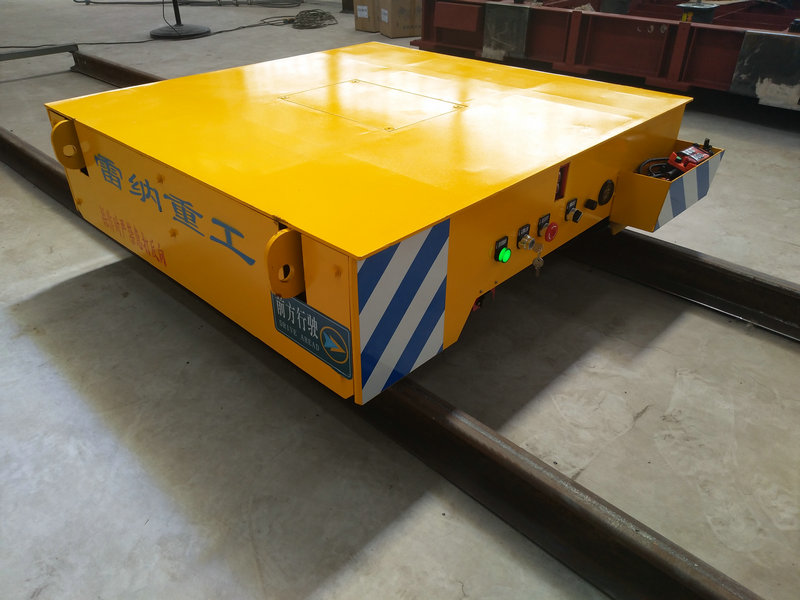

The Remote Control Heavy Load Rail Carriage is a robust and intelligent material handling solution designed to streamline heavy-duty transportation across factory production lines. Engineered for demanding industrial applications, this rail-guided transfer vehicle ensures stable performance, precise movement, and high load-bearing capacity, making it ideal for long-distance, repetitive, and automated material flow.

Core Features

1. Heavy Load Capacity

Built with high-strength steel frames and reinforced structures, the carriage supports 10–300 tons of materials such as:

Steel components

Large molds

Machinery parts

Assembly modules

This ensures safe transport even under continuous high-load operations.

2. Remote Control Operation

Equipped with an ergonomic wireless remote controller, operators can manage:

Start/stop functions

Forward & reverse motion

Speed adjustment

Safety braking

Positioning alignment

Remote control improves operational flexibility and ensures safety by keeping workers away from hazardous zones.

3. Smooth and Stable Motion

A low-noise motorized drive system combined with a heavy-duty wheel set ensures:

Smooth acceleration & deceleration

Reduced mechanical wear

High tracking accuracy on the rail

Safe movement in confined factory environments

Power Supply Options

Depending on the factory layout, the carriage can be configured with various power modes:

✔ Low-voltage rail power – continuous operation without charging

✔ Battery power – flexible movement across long distances

✔ Cable reel / drag chain – cost-effective for fixed routes

Each mode is tailored to match operational needs and energy-efficiency requirements.

Advanced Safety Systems

To ensure secure transport of high-value loads, the equipment integrates multiple safety protections:

Emergency stop buttons

Overload protection

Anti-collision sensors

Speed limitation system

Audible & visual alarms

Electric braking

These features significantly reduce risks in busy production environments.

Customizable for Production Lines

The rail carriage can be fully customized to match different industries and workflows:

Custom load capacity

Table size & deck structure

V-frame / U-frame / lifting platform

Synchronous control with PLC

Integration with automated production systems

Suitable for industries including metal fabrication, automotive, mold manufacturing, heavy machinery, and more.

Key Benefits for Your Factory

Boosts productivity by reducing manual handling and downtime

Improves safety by minimizing direct human–load interaction

Ensures consistency with precise and stable movement

Lower maintenance costs with durable, industrial-grade components

Flexible operation with remote control and multiple power configurations

Applications

The Remote Control Heavy Load Rail Carriage is widely used for:

Workshop-to-workshop material transfer

Production line feeding

Mold and tooling handling

Large component assembly flows

Storage and warehouse connection