The Remote Control Heavy Load 50 Ton Cable Powered Rail Vehicle is a heavy-duty rail-guided transport solution designed for industrial plants, steel mills, foundries, and large manufacturing workshops.

With a rated load capacity of 50 tons, this vehicle is engineered to transport extremely heavy materials such as steel structures, molds, ladles, and large machinery components safely and efficiently.

Powered by a cable reel power supply system and operated via wireless remote control, the vehicle delivers continuous power, precise movement, and high operational safety for demanding industrial applications.

Key Features

Cable Powered Drive System

Continuous electric power supplied through an automatic cable reel.

Ideal for long-distance travel and high-duty cycle operations.

Stable power output ensures consistent performance under heavy loads.

50 Ton Heavy-Duty Load Capacity

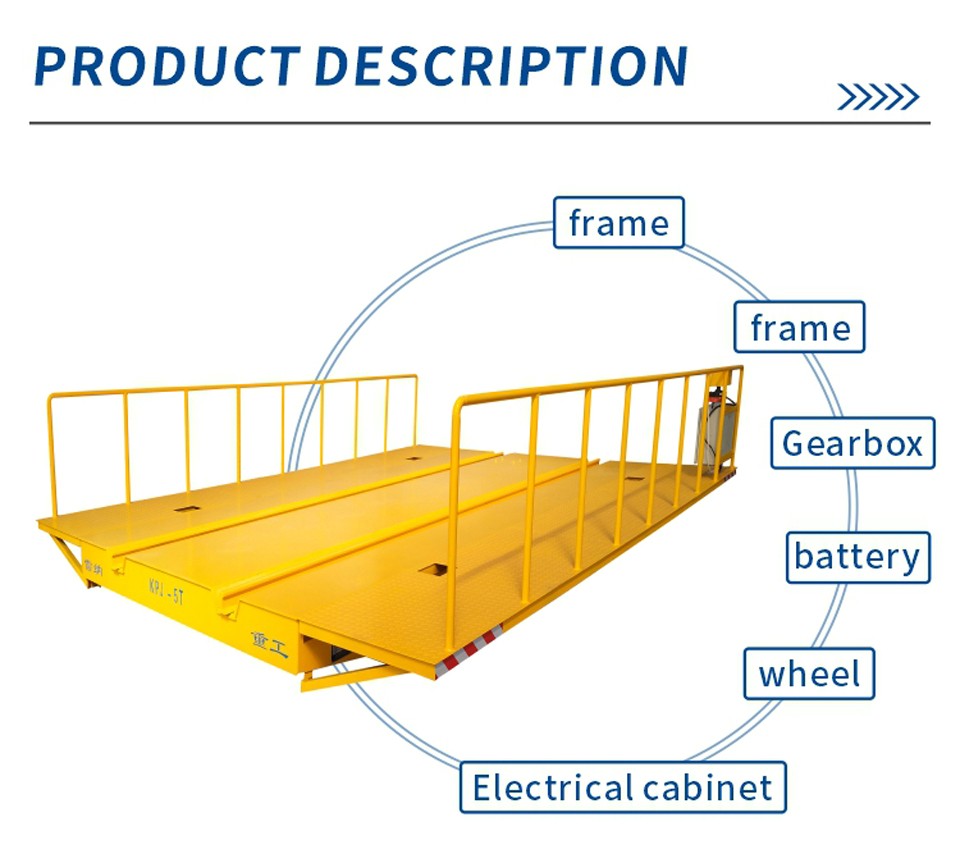

Reinforced steel frame designed for extreme load conditions.

Optimized wheel and axle structure for high concentrated loads.

Excellent stability and durability during full-load operation.

Wireless Remote Control Operation

Allows operators to control movement from a safe distance.

Forward, reverse, speed adjustment, and emergency stop functions.

Improves safety when handling heavy or hazardous materials.

Rail-Guided Precision Movement

Runs on fixed steel rails for predictable and accurate travel paths.

Precision-machined rail wheels ensure smooth operation and reduced wear.

Suitable for straight, curved, and multi-station rail layouts.

Comprehensive Safety Protection

Emergency stop system and overload protection.

Audible and visual warning alarms during operation.

Optional anti-collision sensors, buffer stops, and limit switches.

Technical Description

This cable powered rail vehicle operates on steel rails and is driven by an electric motor through a heavy-duty reduction gearbox.

The 50-ton rated load capacity is designed with an industrial safety factor to withstand demanding operating conditions.

The cable reel system automatically manages cable winding and unwinding to prevent tangling and excessive tension.

Operating speed is adjustable to meet safety and process requirements.

Platform size, rail gauge, and wheel configuration can be customized to match plant layouts and specific transport needs.

Typical Applications

Steel Mills & Foundries – Transport of steel structures and molten material containers.

Heavy Manufacturing Plants – Movement of large machinery and components.

Mold & Die Workshops – Handling of oversized molds and tooling.

Industrial Assembly Lines – Heavy material transfer between workstations.