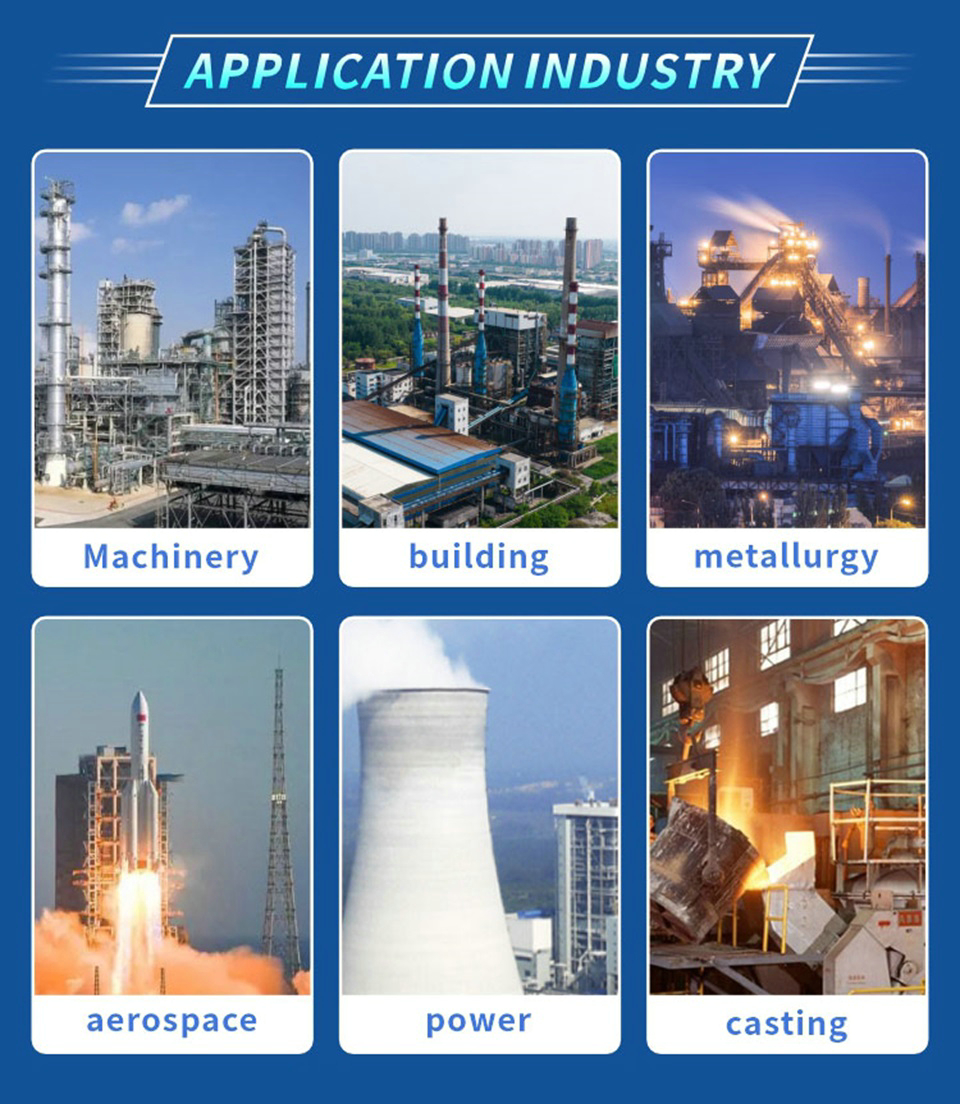

The Industrial Warehouse Material Handler is an efficient, safe, and environmentally friendly internal transport device for workshops and warehouses. It is widely used in manufacturing, logistics and warehousing centers, metallurgy, machining, mold production, and other applications.

This device operates on pre-set rails in the workshop and is battery-powered, eliminating the need for external cables or high-voltage power systems, enabling flexible scheduling and stable operation.

It can replace traditional transport methods such as forklifts and manual push carts, effectively addressing issues such as low labor efficiency, poor safety, and limited transport distances. It is a vital transport tool for modern factories and warehouse logistics systems. Core Value:Through intelligent rail transport, it improves internal logistics efficiency, reduces operating costs, and helps companies transition to automated and intelligent factories.

Xinxiang LEINA Heavy Industry Machinery Co., Ltd. specializes in customized production of 1-500 ton industrial rail transfer carts, electric trackless transfer carts, electric lifting transfer carts, rail traction trolley and other handling equipment. All of them have passed ISO, ECPSC, CE authoritative certifications

LEINA has over 23 years of industry experience, leading technology. There are various types of transfer Carts with complete specifications. Factory direct supply prices provide higher cost-effectiveness

Used for spray painting rooms in the oil and gas industry, chemical industry, etc., it can be used in risk environments such as explosion-proof, waterproof, and high temperature resistance.

So far, LEINA Industrial Transfer Cart has been directly exported to more than 50 countries and regions around the world, basically covering Asia, Central and Eastern Europe, North America and Latin America. It has successfully solved the transportation problems for tens of thousands of companies at home and abroad.

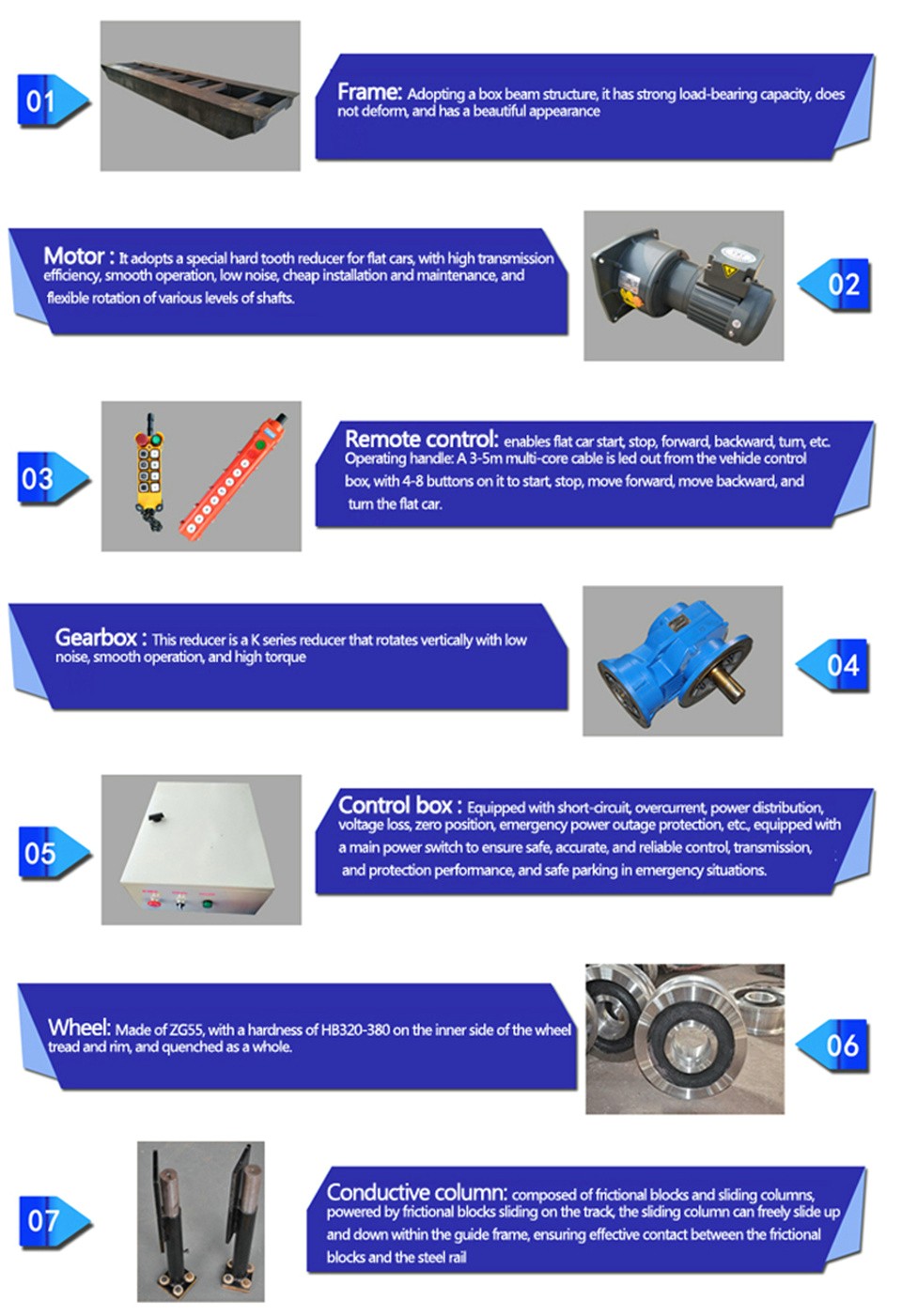

Product Features

1. Efficient Transport

Precise and stable rail operation with adjustable speed supports long-distance transport.

It is suitable for batch and multi-batch material turnover, significantly improving logistics efficiency.

It can be integrated with a warehouse management system (WMS) or a production line management system (MES) for automated scheduling.

2. Safe and Reliable

Equipped with multiple safety features, including an audible and visual alarm system, an emergency stop button, and position limit protection.

Travel-guided operation prevents pedestrians from mixing with other vehicles, minimizing safety hazards associated with forklift operations.

Soft start and stop functions reduce impact on materials, protecting both the transported goods and the equipment itself.

3. Battery-Powered, Environmentally Friendly

Using rechargeable or lithium batteries, it offers zero emissions and low noise levels.

No high-voltage cables are required, impacting the factory structure and layout.

Batteries can be quickly replaced or centrally charged, minimizing downtime.

4. Customizable Design

Customizable to suit warehouse layout and cargo type:

Tabletop Structures: Flatbed, V-Bracket, Guardrail, Roller Conveyor

Control Systems: Handle Control, Wireless Remote Control, PLC Automation

Functional Extensions: Automatic Docking, Hydraulic Lift, Weighing System, and more.

Meet the diverse needs of different production lines and warehouse logistics processes.

5. Cost Optimization

Replaces traditional forklifts and manual transport, reducing labor costs;

Low maintenance costs and long service life of key components;

Suitable for continuous operation, achieving a high long-term input-output ratio.

Applicable Scenarios

This equipment can be widely used in various industrial and warehousing environments:

Warehouse and logistics centers

Bulk transport of cargo pallets and packaging boxes;

Material transfer between automated high-bay warehouses and production workshops.

Manufacturing plants

Sorting and transport of raw materials from warehousing to production lines;

Continuous transfer of parts between workstations.

Metallurgical Industry

Stable handling of heavy materials such as ingots, coils, and furnace charges.

Mold and Machinery Industry

Intra-workshop transfer of medium-to-large molds and equipment components.

Electronics Manufacturing and Precision Machining

Smooth transportation of precision parts, preventing damage caused by manual handling.

Customized Solutions

We offer a variety of customized options to meet the specific needs of different customers:

Structural Customization:

Flatbed structure, suitable for transporting general materials;

V-shaped bracket, suitable for transporting cylindrical or coiled materials;

Roller conveyor, directly connected to conveyor lines;

Lifting platform, suitable for connecting workstations at different heights.

Battery Options:

Lead-acid or lithium battery options available;

Backup battery and quick-change solutions available to ensure uninterrupted operation.

Control System:

Handle control for manual operation;

Wireless remote control for single-person remote control;

PLC fully automatic control, directly integrated with production lines or warehouse systems.

Safety Upgrades:

LiDAR obstacle avoidance;

Infrared sensor collision avoidance system;

Audio-visual alarm and emergency braking system.

Packaging & Shipping