The Industrial Electric Turntable Rail Transport Trolley is a specialized material handling solution designed for factories, production lines, steel plants, and machining workshops where materials must be transferred between multiple rail directions.

By integrating an electric turntable mechanism into a rail transport trolley, this system allows loads to be rotated, aligned, and transferred smoothly between intersecting or perpendicular rail tracks.

This trolley significantly improves layout flexibility, reduces manual handling, and enhances operational efficiency in complex industrial logistics systems.

Key Features

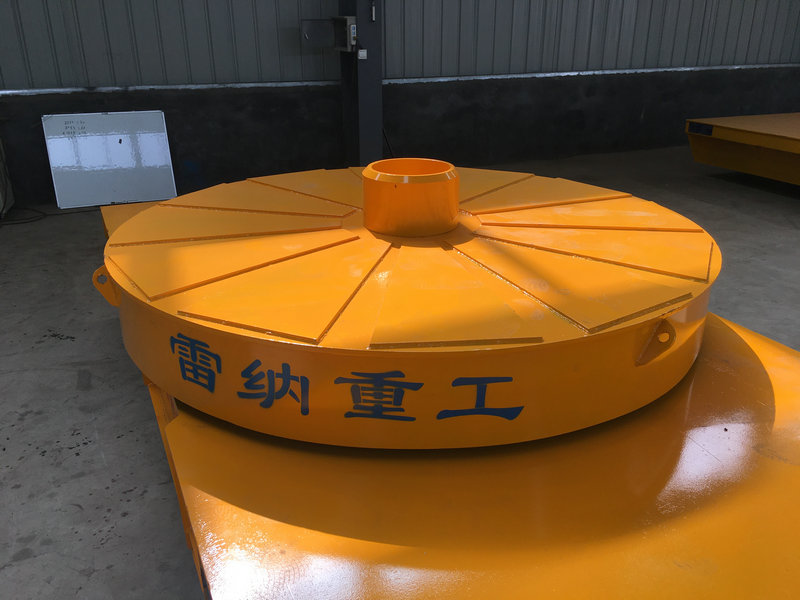

Electric Turntable & Drive System

Integrated electric motor provides smooth 360-degree rotation of the turntable platform.

High-torque drive system ensures stable rotation even under heavy loads.

Supports seamless transfer between straight, cross, or circular rail layouts.

Heavy-Duty Load-Bearing Structure

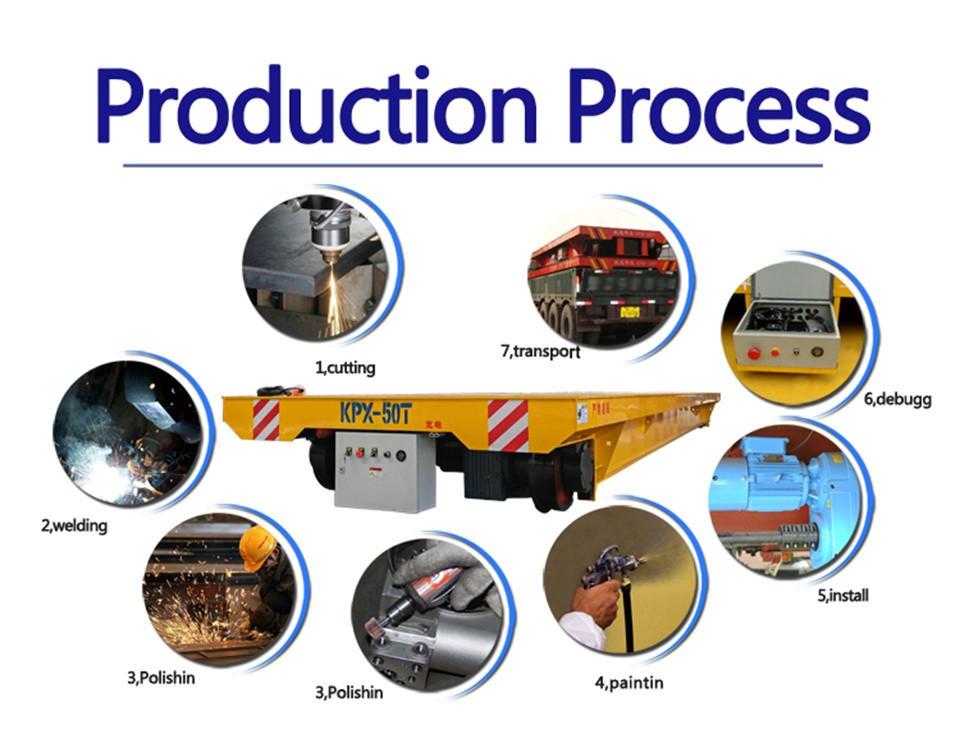

Constructed from high-strength welded steel plates and reinforced beams.

Designed to handle heavy and concentrated loads with excellent stability.

Suitable for load capacities ranging from 10 tons to over 200 tons (customizable).

Precision Control & Smooth Operation

Controlled via wired pendant or wireless remote control.

Independent control of travel movement and turntable rotation.

Optional PLC automation enables precise positioning and synchronized operation.

Comprehensive Safety System

Equipped with emergency stop buttons, overload protection, and audible/visual alarms.

Mechanical locking devices ensure secure alignment with rail tracks during transfer.

Designed to comply with CE and ISO industrial safety standards.

Technical Description

The industrial electric turntable rail transport trolley operates on fixed steel rails and integrates a motor-driven turntable at its center.

The turntable rotation angle can be set to 90°, 180°, or 360°, depending on rail layout requirements.

The trolley travel speed typically ranges from 0–20 meters per minute, while the turntable rotates smoothly at a controlled speed to ensure safe load handling.

Power supply options include battery power, low-voltage rail power, or cable reel systems, selected according to site conditions.

The platform can be customized with flat decks, rollers, V-shaped supports, or special fixtures to match the transported materials.

Typical Applications

Manufacturing Plants — Transfer of heavy parts between intersecting production lines.

Machining Workshops — Precise alignment of workpieces with machine tools.

Automotive & Mold Industry — Movement and positioning of molds and dies.

Steel & Metal Processing — Rail-based handling of plates, billets, and structures.

Industrial Warehouses — Direction-changing transport in limited space layouts.

Advantages

This industrial electric turntable rail transport trolley offers exceptional flexibility for complex rail systems.

Its integrated electric turntable enables smooth and accurate rotation, allowing materials to be transferred between multiple rail directions without manual repositioning.

The heavy-duty structure ensures stable and safe operation even under high load conditions.

Precise control of both movement and rotation improves positioning accuracy and reduces operational errors.

With multiple power supply options and extensive customization capabilities, the trolley can be tailored to various industrial environments and layout requirements.

Comprehensive safety mechanisms further ensure reliable and secure operation during both transport and rotation.