The Industrial Electric Rail Transfer Cart for Workshop Raw Materials is a reliable and efficient material handling solution designed for manufacturing workshops, production lines, and industrial warehouses.

It is specifically engineered to transport raw materials, semi-finished products, and heavy industrial components safely and smoothly along fixed rail systems inside factories.

Driven by an electric power system, this rail transfer cart ensures stable movement, precise control, and continuous operation, making it an ideal choice for factories seeking to improve internal logistics efficiency and reduce manual handling.

Key Features

Electric-Powered Drive System

Provides strong and consistent driving force for heavy material transport.

Available power options include battery supply, low-voltage rail power, or cable reel, depending on workshop layout.

Designed for long service life with low maintenance requirements.

Heavy-Duty Structure for Raw Materials

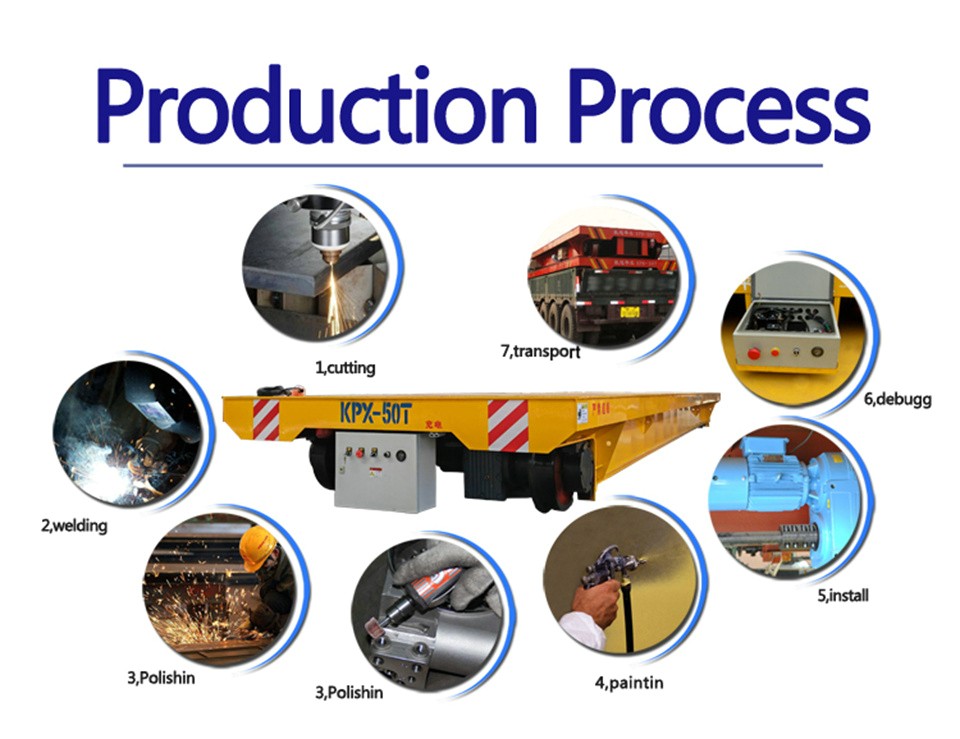

Manufactured with high-strength welded steel plates and beams.

Ensures excellent load-bearing capacity and resistance to deformation.

Smooth rail-guided travel protects raw materials from impact and vibration.

Flexible Control & Smooth Operation

Operated via wired pendant or wireless remote control.

Features soft start and soft stop to prevent material shifting.

Optional PLC control for automated or semi-automated workflows.

Integrated Safety Protection

Equipped with emergency stop, audible/visual alarms, and overload protection.

Optional anti-collision sensors and speed limit zones enhance operational safety.

Complies with international industrial safety standards such as CE and ISO.

Technical Description

This industrial electric rail transfer cart operates on a fixed steel rail system and is powered by an industrial-grade electric motor combined with a reduction gearbox.

The cart supports a wide range of load capacities, typically from 5 tons to over 300 tons, depending on design requirements.

Standard travel speed ranges from 0–20 meters per minute, adjustable according to transport conditions.

The power system can be configured as battery-powered, low-voltage rail-powered, or cable-powered, ensuring compatibility with different factory environments.

The platform can be customized with side guards, V-type supports, rollers, or lifting mechanisms to accommodate various raw material forms such as steel plates, coils, billets, or pallets.

Typical Applications

Manufacturing Workshops — Transport of steel plates, bars, billets, and castings.

Machining Centers — Feeding raw materials to CNC machines and processing lines.

Automotive Production — Movement of metal blanks and structural components.

Construction Material Plants — Handling precast parts and heavy raw materials.

Industrial Warehouses — Internal distribution of bulk materials.

Advantages

This industrial electric rail transfer cart offers a dependable solution for workshop raw material handling.

Its electric drive system delivers smooth and reliable power, ensuring consistent performance even under heavy loads.

The rail-guided design guarantees stable movement and precise routing, reducing the risk of material damage and operational accidents.

With flexible power supply options, the cart can be easily integrated into different factory layouts and production processes.

The robust steel structure and comprehensive safety features provide long-term durability and safe operation.

Moreover, its high degree of customization allows the cart to be tailored to specific raw material types, load capacities, and workflow requirements, making it a cost-effective and efficient logistics solution for industrial workshops.