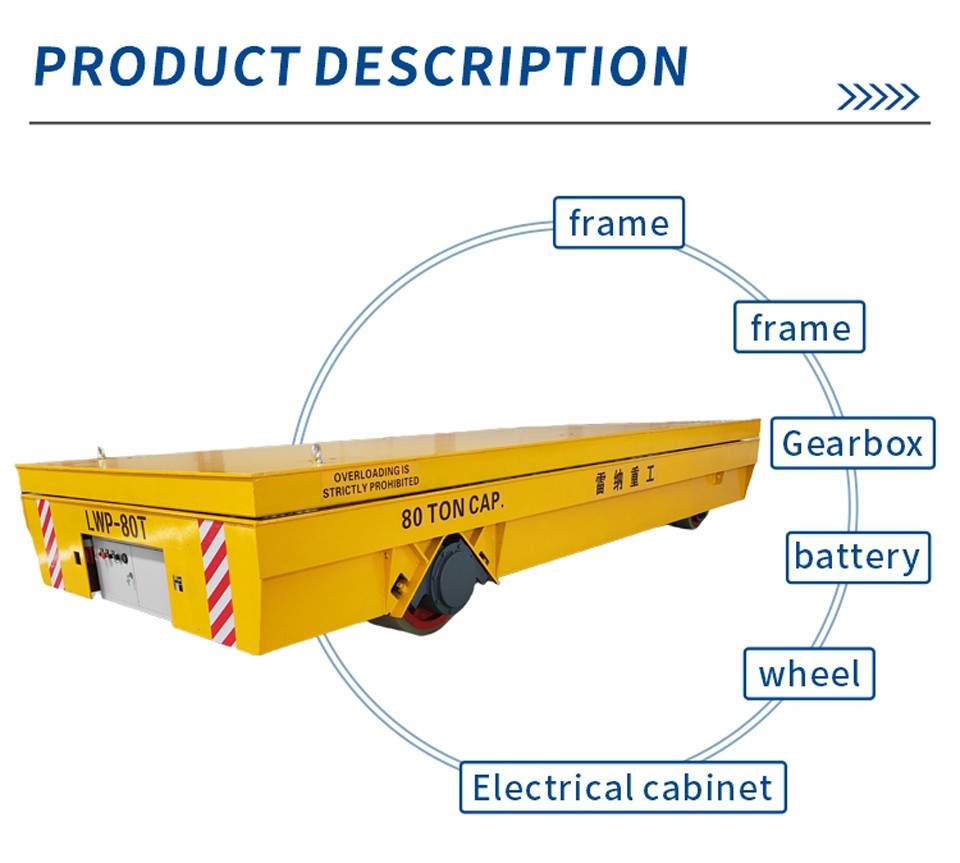

The Industrial Battery Powered 30T Transport Cart with Support Structure is a heavy-duty material handling solution designed for reliable and efficient movement of large loads across factory workshops and production lines. Engineered with a robust steel frame and an integrated support structure, this transport cart ensures safe handling of high-value components such as molds, coils, machinery parts, and oversized industrial equipment.

Powered by high-capacity industrial batteries, the cart delivers strong traction, long travel distance, and stable operation without relying on rails or external power cables. The onboard drive system supports smooth acceleration, controlled speed adjustment, and precise maneuvering—even under full 30-ton load conditions.

Key Features

Battery Powered for Flexible Operation

Equipped with long-life lithium or lead-acid batteries, the cart offers continuous operation with minimal maintenance and no cable restrictions, making it ideal for dynamic factory workflows.

Heavy-Duty 30 Ton Load Capacity

Designed with an enhanced structural frame and integrated support system to ensure maximum rigidity, stability, and safety during heavy load transport.

Customizable Support Structure

The functional platform can be customized with:

Reinforced support beams

Mold clamping brackets

Coil V-blocks

Hydraulic lifting system

Anti-slip plates

This ensures compatibility with various industrial materials and transport requirements.

Precise Steering & Controlled Movement

The transport cart features smooth driving control with:

Soft start/stop technology

Adjustable speed

Optional dual-control modes (remote + onboard control)

Reliable electromagnetic braking system

Enhanced Safety Protection

Standard safety features include emergency stop buttons, audible warnings, overload alarms, and optional laser anti-collision sensors for secure operation in busy workshop environments.

Applications

The 30T battery powered transport cart is widely used in:

Automotive and Mold Workshops – die and mold transport

Steel Plants and Coil Processing Lines – coil, slab, and heavy billet handling

Machinery Manufacturing – movement of large equipment assemblies

Aerospace & Defense Industries – precision heavy component transfer

General Industrial Logistics – flexible material flow across production zones

Benefits

No track construction required, reducing installation cost

High load-bearing capability for heavy-duty industrial applications

Smooth, quiet, and energy-efficient electric drive system

Highly customizable to match specific factory needs

Improves workflow efficiency and materials safety