The Heavy Load Electric Rail Mounted Transfer Wagon for Molds is a robust and efficient material handling solution specifically engineered for the safe transportation of heavy molds and dies within manufacturing facilities.

It is widely used in mold workshops, die-casting plants, stamping lines, and heavy equipment factories, where precise positioning and stable movement of large molds are critical.

With its electric drive system and rail-guided design, the transfer wagon ensures smooth, controlled, and repeatable mold movement, reducing manual handling and improving production efficiency.

Key Features

Electric Motorized Drive System

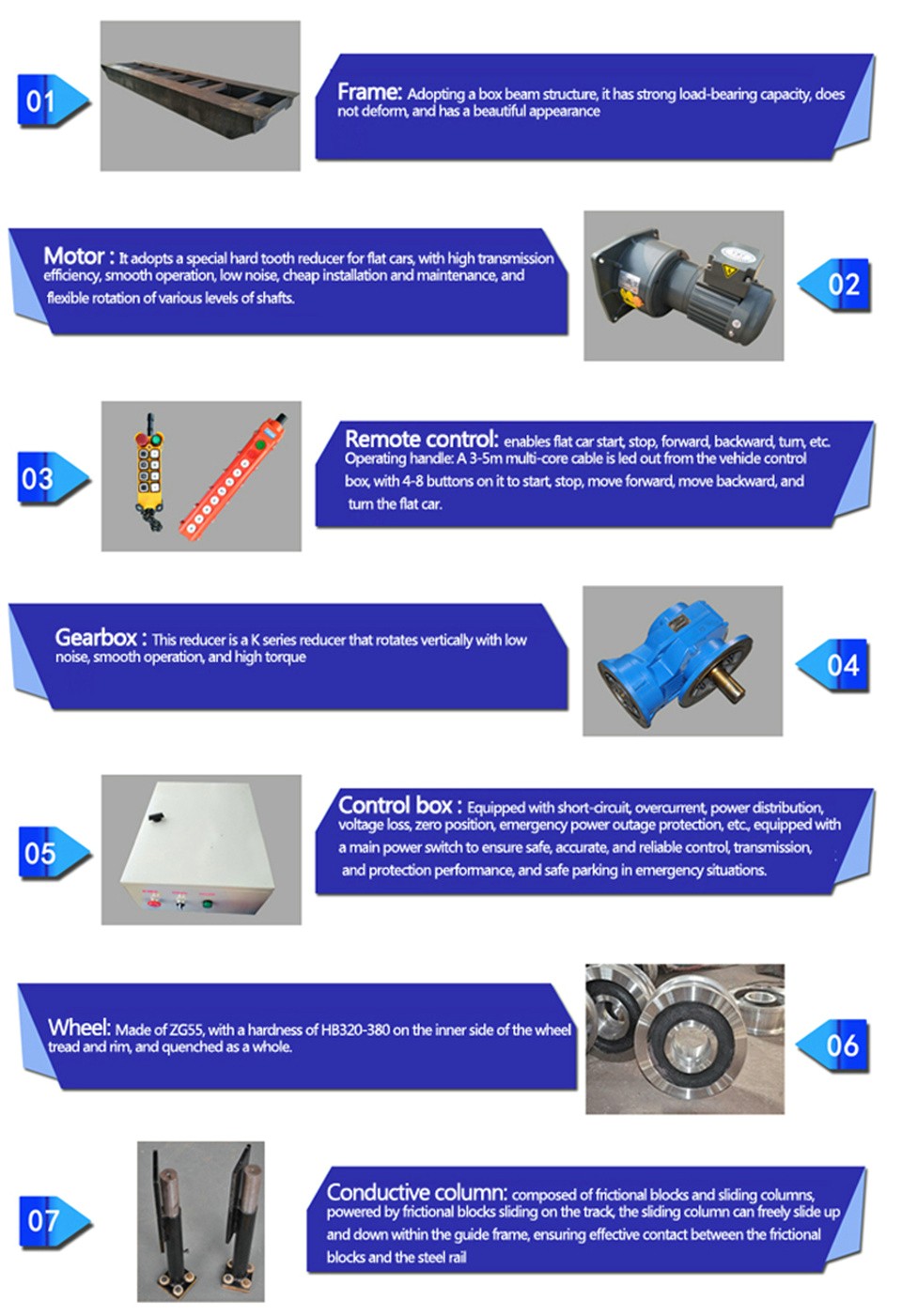

High-torque electric motor combined with an industrial gearbox for heavy mold transport.

Smooth acceleration and deceleration minimize vibration and protect mold surfaces.

Multiple power options available, including battery power, low-voltage rail supply, or cable reel systems.

Heavy-Duty Structure for Mold Loads

Reinforced steel frame designed to handle high concentrated loads.

Flat or customized platforms to support various mold sizes and shapes.

Precision-machined rail wheels ensure stable and accurate travel on tracks.

Precise Control & Positioning

Operated via wired pendant control or wireless remote control.

Adjustable speed enables accurate positioning at molding machines or storage areas.

Optional PLC control for automated mold transfer processes.

Comprehensive Safety System

Emergency stop and overload protection for safe operation.

Audible and visual alarms during movement.

Optional anti-collision sensors, limit switches, and buffer stops.

Technical Description

This electric rail mounted transfer wagon runs on fixed steel rails and is driven by an electric motor through a heavy-duty reduction gearbox.

Load capacity can be customized from 5 tons to over 200 tons, depending on mold weight and handling requirements.

The operating speed is adjustable to meet safety and process demands.

The platform size, wheel configuration, and rail gauge can be customized to match existing workshop layouts.

Optional features such as lifting mechanisms, rollers, or turntables can be integrated to enhance mold handling efficiency.

Typical Applications

Mold Manufacturing Workshops – Transport of injection molds and tooling.

Die Casting Plants – Movement of large dies between machines.

Stamping Lines – Handling of press molds and dies.

Heavy Equipment Manufacturing – Internal mold and tooling transport.

Advantages

This heavy load electric rail mounted transfer wagon provides a reliable solution for mold handling operations.

Its electric drive system ensures smooth and controllable movement under heavy loads.

The rail-mounted design offers excellent stability and repeatable travel paths.

The reinforced structure supports high concentrated mold loads while maintaining long service life.

Flexible customization and integrated safety features allow the wagon to adapt to different mold handling processes and improve overall operational safety.