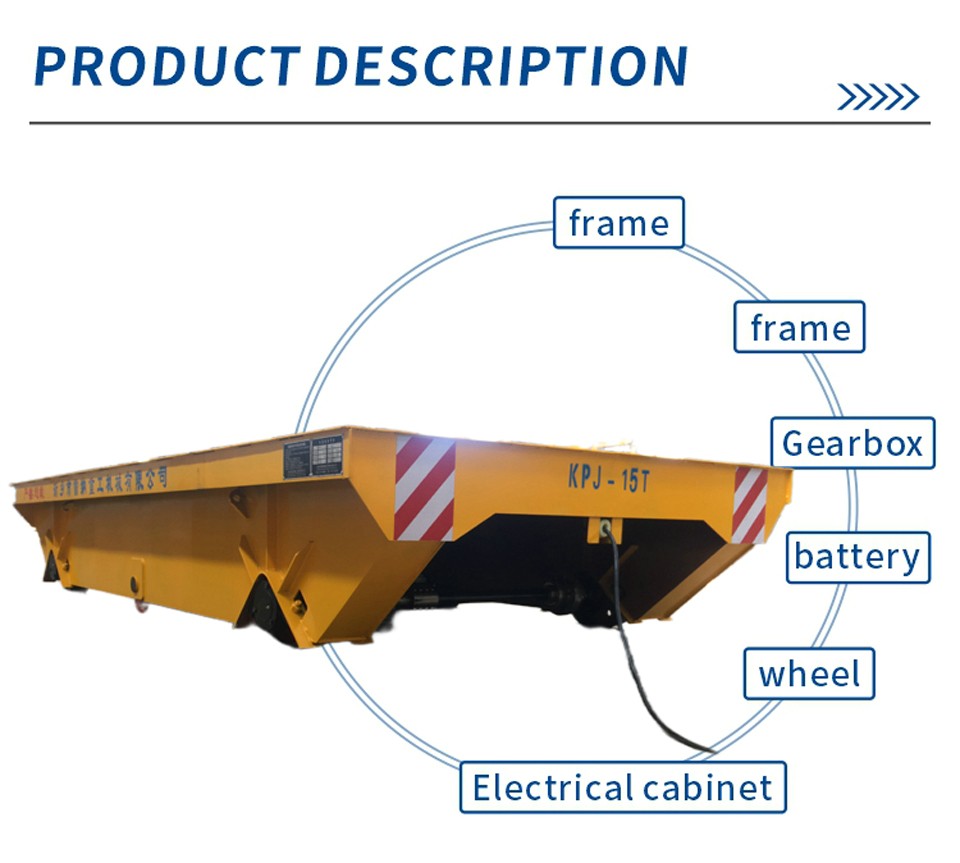

The Custom V-Deck Rail Coil Handling Transfer Car is a specialized rail-guided transport solution engineered for the safe, stable, and efficient movement of steel coils, aluminum coils, wire rolls, and other cylindrical materials within industrial facilities. Designed with a reinforced V-shaped deck (single or double V-frame), this transfer car ensures secure coil positioning, preventing rolling, shifting, or damage during transportation.

Built on a heavy-duty steel frame and powered by an electric drive system, the coil handling transfer car delivers smooth motion, precise rail-guided navigation, and dependable performance for repetitive coil transfer operations in steel mills, metal processing plants, and manufacturing workshops. Load capacities, V-frame dimensions, and power supply configurations are fully customizable to match specific handling requirements.

Key Features

Custom V-Deck Structure for Coil Safety

Specialized V-shaped cradle securely holds coils in place

Customizable width, depth, and support angle

Optional rubber lining or rollers for coil surface protection

Suitable for single-coil or multi-coil loading

Rail-Guided Stable Movement

Runs on fixed steel rails, ensuring highly controlled, straight-line or curved-path transportation with minimal vibration and maximum load stability.

Flexible Power Options

Available power configurations include:

Battery powered (corded-free operation)

Cable reel powered

Dragging cable powered

Low-voltage rail powered (36V/48V/72V)

Heavy-Duty Load Capacity

Customizable from 5 tons to 200+ tons, depending on coil size and production requirements.

Easy Operation

Supports multiple control modes:

Handheld remote control

Onboard control panel

Optional PLC automation for fully automated coil handling lines

Advanced Safety Protection

Equipped with emergency stop buttons, overload alarms, soft-start/stop control, buffer protection, and optional laser obstacle detection.

Applications

The Custom V-Deck Rail Coil Handling Transfer Car is ideal for transporting coils in:

Steel mills and metal processing plants

Rolling mills and slitting production lines

Coil storage and distribution zones

Machinery and fabrication workshops

Logistics and warehouse systems

Benefits

Enhances safety by preventing coil rolling or shifting

Reduces forklift usage and manual handling risks

Provides consistent, precise coil transfers on fixed rail routes

Low maintenance and long service life

Completely customizable to match production line layout and coil specifications