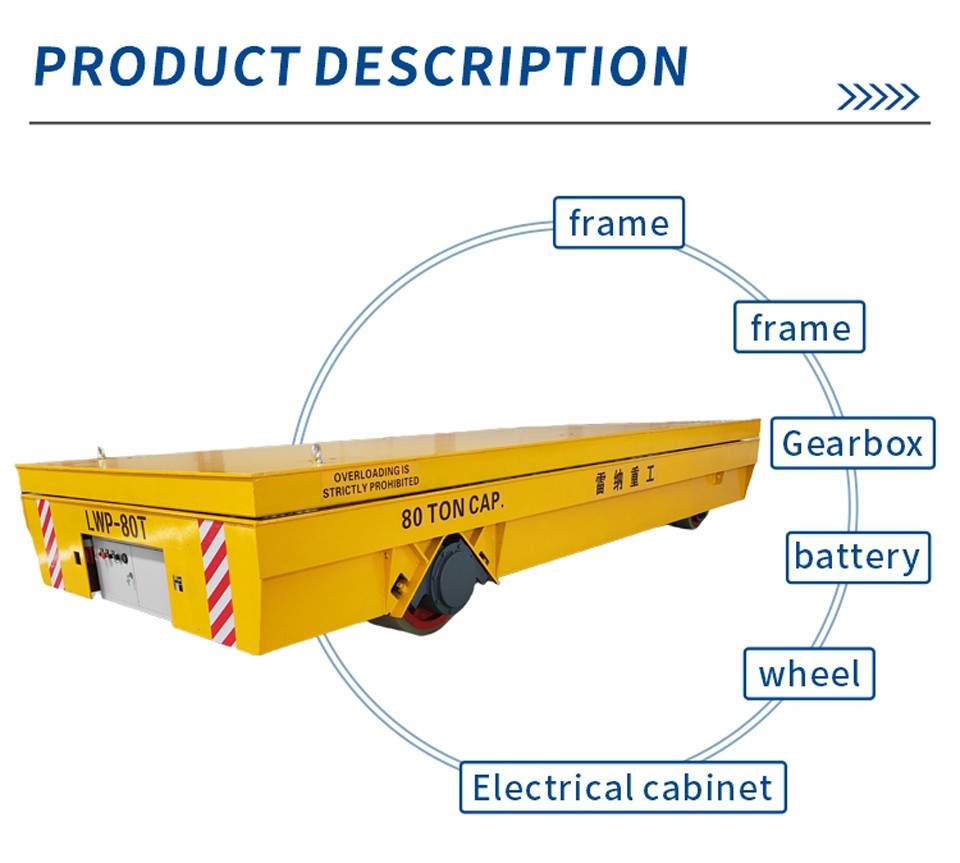

The Heavy Duty Remote Trackless Transfer Vehicle for Workshops is a high-capacity, battery-powered material handling solution designed for the safe, flexible, and efficient transportation of heavy loads across factory floors.

With its trackless design, remote-controlled operation, and heavy-duty structural construction, this vehicle provides exceptional mobility and reliability for demanding industrial environments.

Ideal for transferring molds, steel structures, machinery parts, assemblies, and large components, it offers seamless navigation without the limitations of rails, cables, or fixed routes.

Product Overview

This trackless transfer vehicle uses a maintenance-free industrial battery as its power source, enabling free movement throughout the workshop.

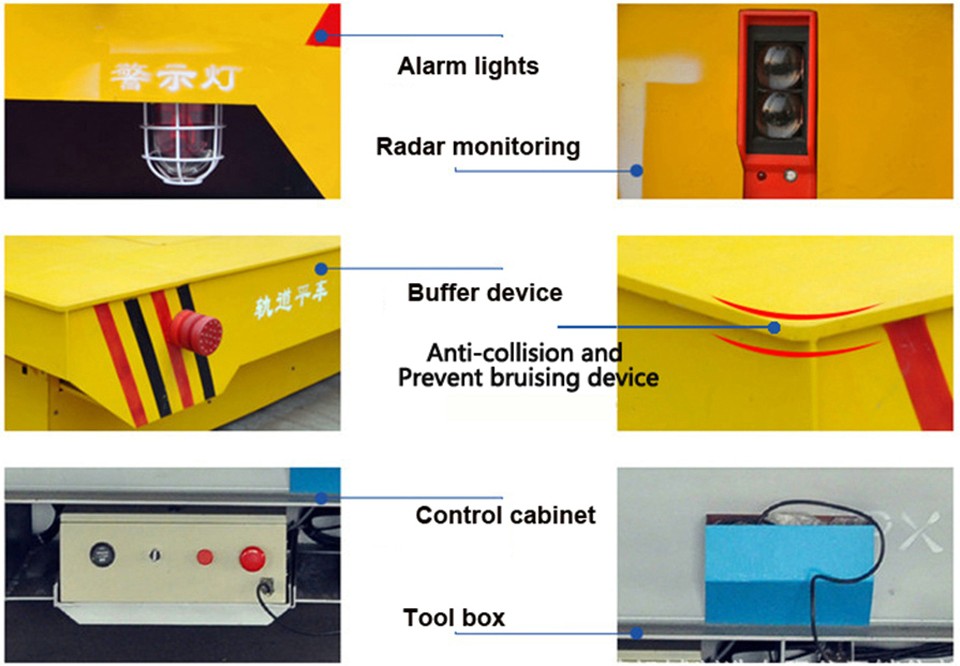

Its remote control system allows operators to guide the vehicle safely from a distance, while precision steering ensures accurate maneuvering in tight spaces, narrow aisles, or complex production layouts.

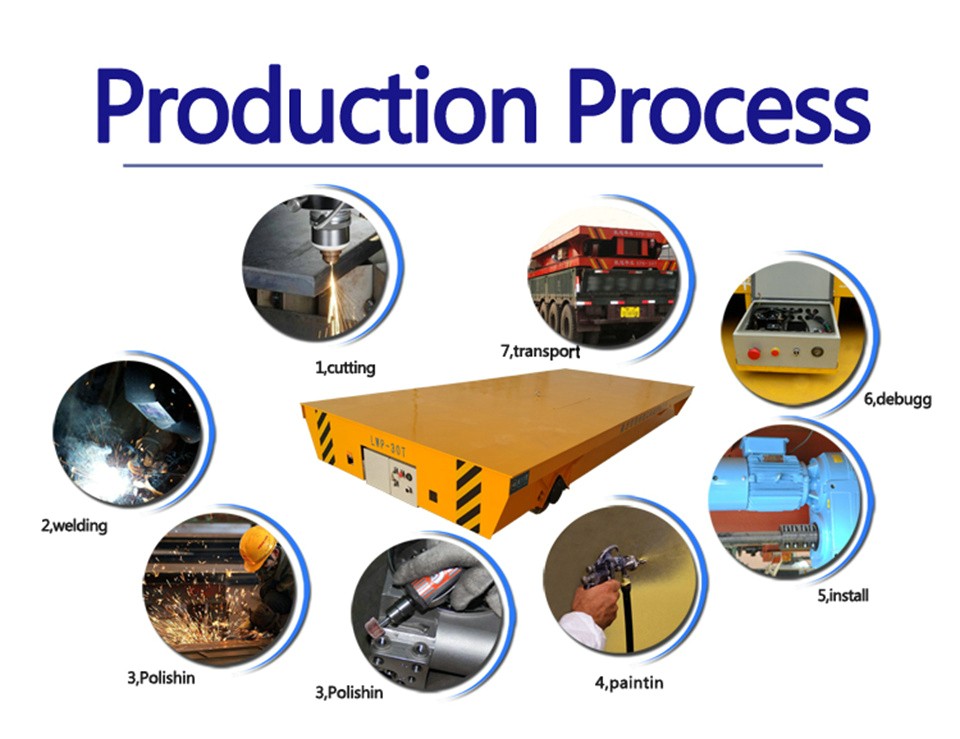

Engineered with a solid welded steel chassis, high-torque drive motors, and advanced safety systems, this vehicle is built to withstand continuous heavy-duty operation.

Key Features

Load Capacity: 5–200 tons (customizable)

Power Source: Lead-acid or lithium battery system

Steering System:

Standard steering

Differential steering

Omnidirectional (360° Mecanum steering available)

Drive System: Dual motor drive with soft-start control

Platform Design: Flat deck, V-frame, fixture rack, or customized structures

Control Mode: Wireless remote + onboard control panel

Speed Range: 0–20 m/min adjustable

Operation Surface: Smooth concrete, epoxy floors, workshop pavement

Wheel Options: Polyurethane, rubber, or solid tires

Performance Advantages

Trackless & Highly Flexible Movement

No rails required — perfect for changing production layouts.

Flexible steering allows sideways movement, diagonal movement, and tight turning.

Remote-Controlled Operation

Ensures operator safety by maintaining a safe distance.

Easy handling for mold alignment, positioning, or docking to machinery.

Heavy-Duty Load Handling Capability

Reinforced chassis ensures stability under extreme loads.

Low bed height for easy loading and safe center-of-gravity control.

Efficient & Clean Electric Drive

Zero-emission, low-noise operation suitable for indoor workshops.

High-capacity battery supports long working hours.

Customizable to Workflow

Size, capacity, steering, platform fixtures, and automation level can be tailored.

Optional integration with AGV navigation or factory MES systems.

Applications

Mold transportation (injection, stamping, die casting)

Heavy machinery and equipment handling

Steel structures, plates, and assemblies

Aerospace and automotive component movement

Workstation-to-workstation material transfers

Flexible workshop logistics and material flow