The Electric Cable Reel Rail Transfer Trolley is a durable, rail-guided material handling vehicle designed for efficient load transportation within workshops, assembly lines, and warehouses.

Powered through a cable reel system, it ensures continuous power supply, stable performance, and long service life, making it a cost-effective alternative to battery-powered transfer carts.

Built with high-strength structural steel and precision drive systems, this trolley is widely used for moving molds, steel structures, mechanical parts, and industrial materials in manufacturing and processing facilities.

Main Features

1. Reliable Cable Reel Power Supply

Operates on 380V AC power via an automatic cable reel mechanism.

Provides constant energy for long-duration operation without downtime.

Optional drag chain cable system for shorter transfer distances.

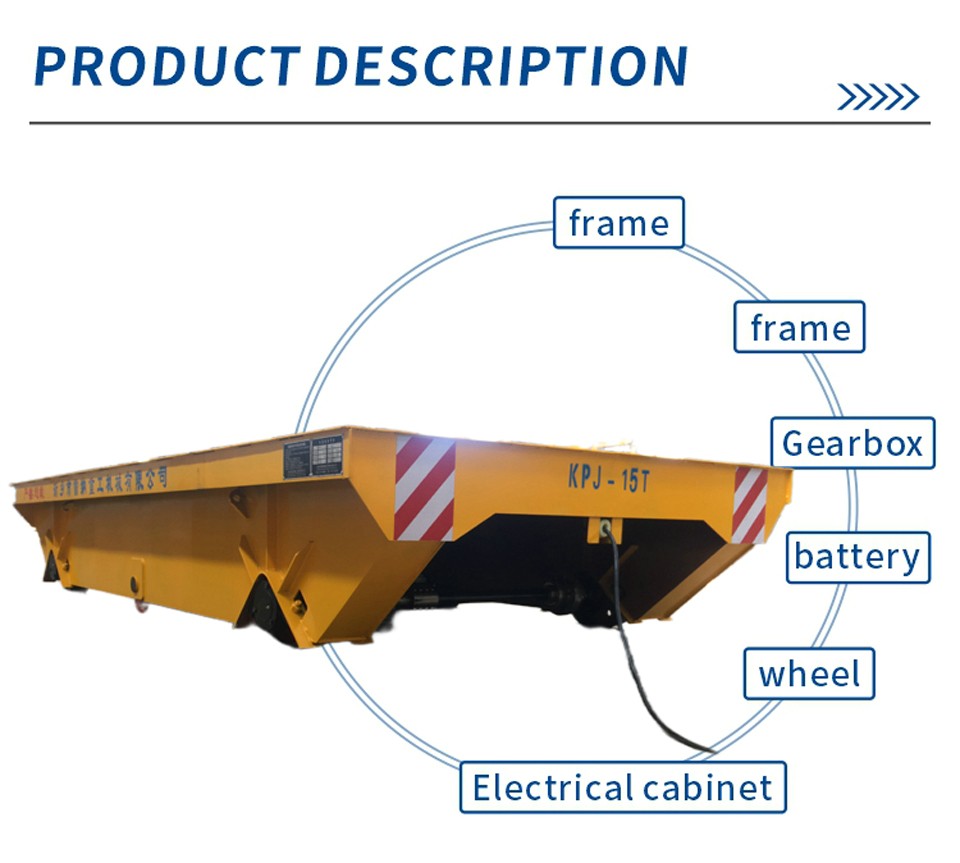

2. Heavy-Duty Construction

Load capacity: 1 to 150 tons (customizable).

Solid welded frame made from industrial-grade Q235 or Q345 steel.

Rail-guided wheels ensure smooth, stable, and safe movement under heavy loads.

3. Safe & Simple Operation

Controlled via wired pendant or wireless remote for flexible operation.

Equipped with emergency stop, speed control, and current overload protection.

Soft start and stop to prevent cargo shifting during movement.

4. Customizable Platform Design

Optional flat deck, V-frame, or fixture mount depending on the load type.

Available with turntable, side rails, or lifting platform configurations.

Can integrate with production lines or warehouse automation systems.

5. Low Maintenance & Long Service Life

Fewer moving parts and no battery replacement required.

Suitable for continuous, high-frequency operation in workshop environments.

Low noise, no emissions, and minimal maintenance cost.