The Customized 30 Ton Omnidirectional Electric Transfer Trolley is an advanced, battery-powered material handling vehicle designed for high-efficiency and flexible movement within industrial facilities.

Equipped with an omnidirectional steering system, this trolley can move forward, backward, sideways, and diagonally, enabling 360° rotation in place — ideal for confined spaces and complex workshop layouts.

Engineered with a heavy-duty structure and customizable platform design, it provides safe, stable, and intelligent transport for molds, steel structures, machinery parts, and other large materials.

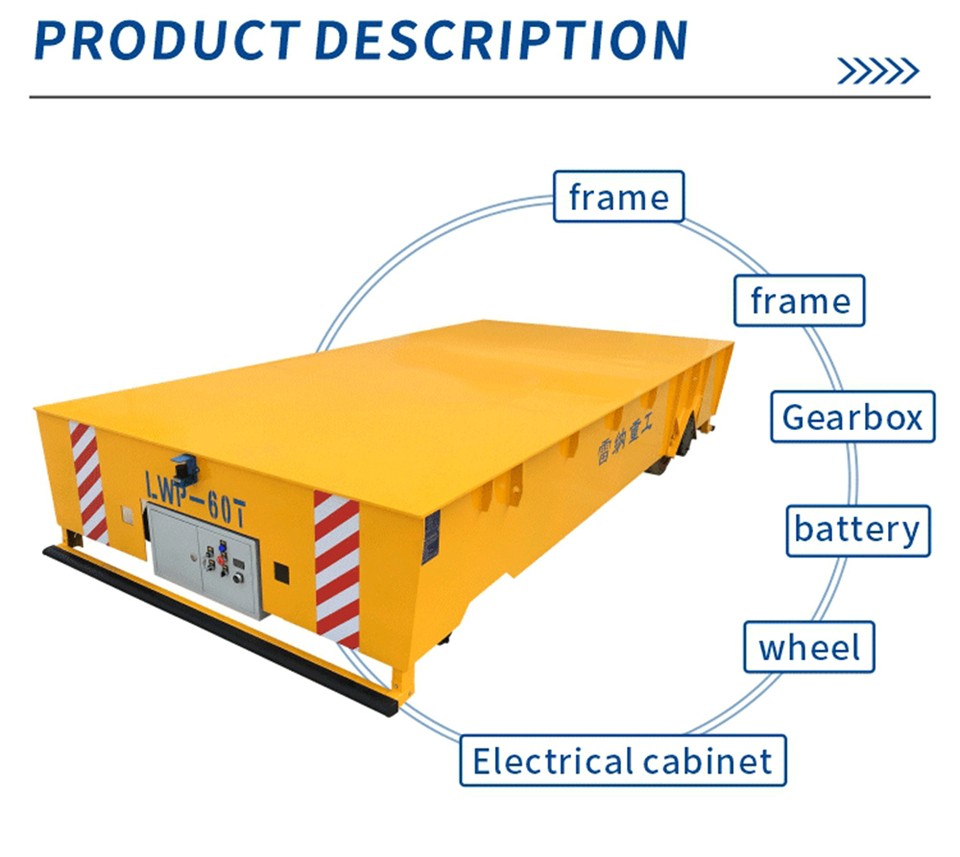

Product Overview

Unlike traditional rail transfer carts, this model is trackless, meaning it can operate freely on smooth factory floors without requiring rails or fixed routes.

The trolley is powered by a high-capacity battery pack, ensuring long endurance, quiet operation, and zero emissions.

With customizable control modes and optional automation functions, it’s the perfect choice for modern workshops pursuing flexible production logistics.

Main Technical Features

Load Capacity: 30 tons (customizable from 10–100 tons).

Power Supply: Industrial battery or lithium battery system.

Drive System: Dual motor drive with differential steering control.

Steering Mode: Omnidirectional (360° rotation, sideway, diagonal).

Frame Structure: Heavy-duty welded steel frame (Q345B or equivalent).

Wheel Type: High-strength polyurethane or solid rubber tires (non-marking).

Operation Mode: Wireless remote control + onboard control panel.

Safety System: Emergency stop, anti-collision sensors, warning lights & buzzer.

Performance Advantages

Omnidirectional Movement

Enables 360° turning and multi-directional travel for maximum flexibility.

Perfect for tight spaces, interbay transport, and complex workshop layouts.

Heavy-Duty Structural Design

Rigid chassis supports continuous loads up to 30 tons.

Designed for high stability and low deformation under heavy weight.

Smart Power System

Maintenance-free battery ensures long operation time and high energy efficiency.

No cable limitations, suitable for both indoor and outdoor operation.

Advanced Safety & Control

Controlled via remote or onboard joystick with speed adjustment.

Equipped with soft start/stop, brake system, and obstacle detection sensors.

Optional PLC control for automatic routing and positioning.

Customizable Design

Platform can be flat, V-shaped, or roller-equipped for coils, molds, or assemblies.

Can integrate hydraulic lifting, turntable, or synchronization system for production automation.

Applications

Mold & die handling — transport of large injection molds or stamping dies.

Steel & metal fabrication — movement of plates, coils, and welded assemblies.

Machinery manufacturing — transfer of engines, components, and machine tools.

Aerospace & shipbuilding — positioning of large structural parts.

Assembly lines & warehouses — smart material transport between stations.