The Battery Operated 10 Ton Trackless Transfer Vehicle is a high-efficiency material handling solution specifically designed for precast concrete production plants and heavy industrial environments.

It allows smooth, cable-free transport of concrete molds, components, and raw materials between production areas — offering unmatched mobility, safety, and reliability.

Powered by a high-capacity rechargeable battery, this vehicle can travel freely on factory floors without rails, making it ideal for dynamic workshop layouts and indoor/outdoor transport tasks.

Key Features

Battery Powered, No Cable Restrictions

Operates independently of any fixed power supply.

Uses long-life lithium or lead-acid batteries for extended operation.

Zero emissions and low noise — ideal for clean indoor environments.

Trackless and Flexible Movement

Can move forward, backward, sideways, or diagonally, and rotate 360°.

Easily navigates complex workshop layouts or narrow spaces.

Suitable for transporting large precast components between workstations.

Strong Load Capacity

Rated 10-ton capacity, engineered with a heavy-duty steel frame.

Excellent stability and durability for continuous industrial use.

Optional U-frame, V-frame, or hydraulic lifting system for concrete molds.

Smart Control System

Operated by wireless remote control or wired pendant.

Smooth speed adjustment ensures safety and precision.

Optional PLC or laser navigation for semi-automatic operation.

Comprehensive Safety Protection

Equipped with emergency stop, acoustic-light alarm, and anti-collision sensors.

Optional laser obstacle detection system for enhanced safety.

Designed to comply with industrial safety and performance standards.

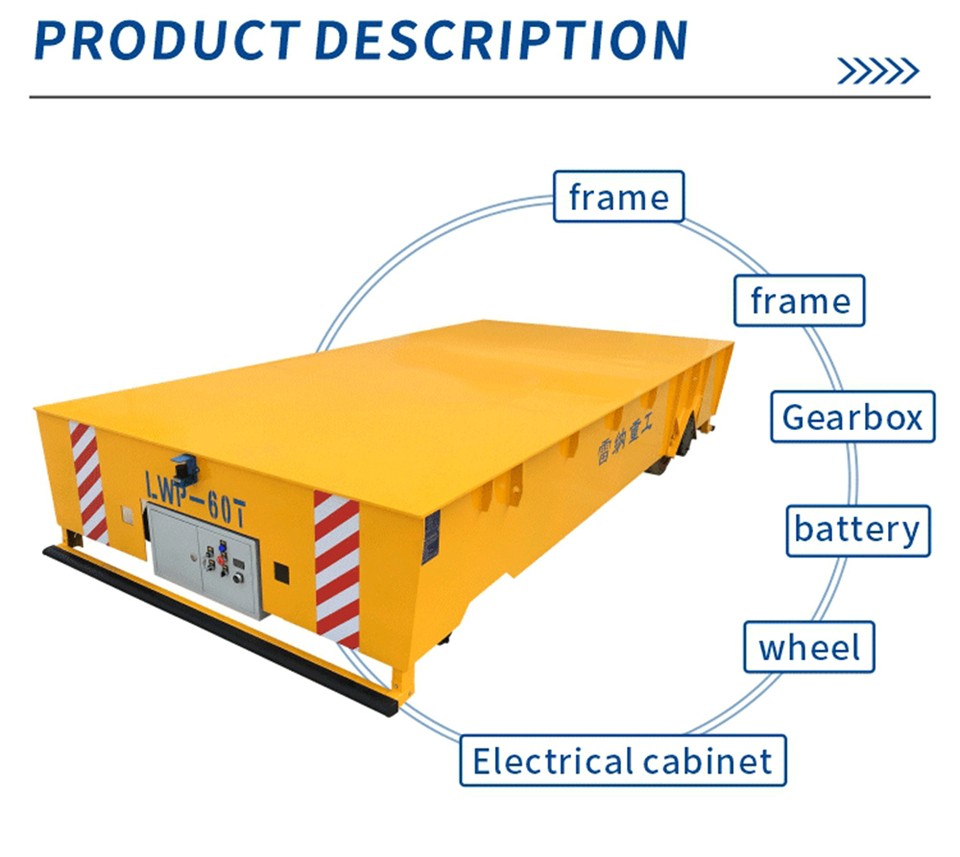

Technical Description

The 10T Trackless Transfer Vehicle adopts a battery-driven traction system that provides continuous power for up to 6–8 hours of operation per charge.

It supports variable speed control ranging from 0–30 meters per minute and can rotate 360° in place for flexible positioning.

The vehicle’s steel frame structure ensures high load-bearing performance and resistance to deformation.

It can be customized with hydraulic lifts, mold fixtures, or tilting platforms to meet various precast handling needs.

Typical Applications

Precast Concrete Production Lines – Transporting concrete molds and formwork.

Construction Material Plants – Handling panels, beams, and slabs.

Infrastructure Projects – Moving heavy precast segments or blocks.

Industrial Manufacturing – Suitable for heavy-duty indoor logistics.