The 80 Ton Heavy Duty Trackless Transfer Car with Integrated Hydraulic Platform Lift is a powerful and flexible material handling solution engineered for heavy-load transportation in industrial workshops, factories, and assembly plants.

Equipped with a battery-driven power system and omnidirectional steering, this transfer car provides unlimited mobility, allowing it to operate freely without rail constraints.

Its integrated hydraulic lifting platform enables precise height adjustment, making it ideal for lifting, alignment, and positioning of large machinery, dies, molds, and steel components.

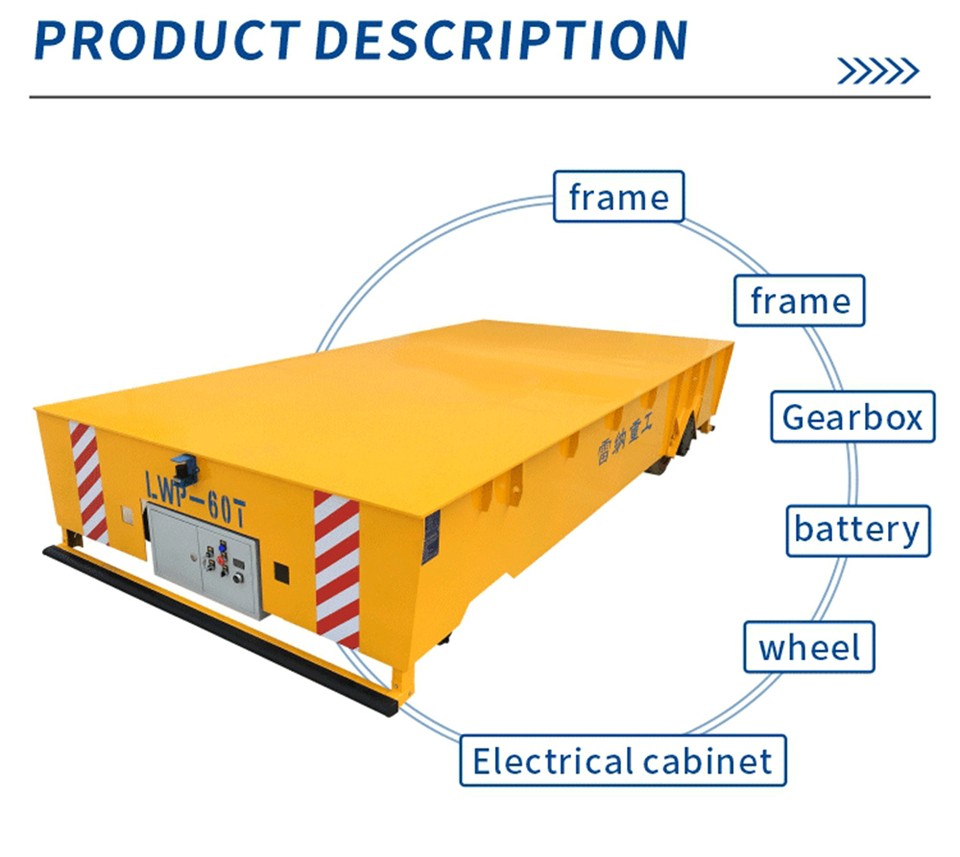

Product Overview

This trackless electric transfer car is designed for indoor and outdoor material handling in environments where rail installation is not feasible.

It runs smoothly on solid rubber wheels and features 360° steering capability, ensuring flexible movement even in narrow workshop aisles.

The built-in hydraulic lifting table provides vertical adjustment for easy loading, unloading, and line-level transfers.

Main Technical Features

Load Capacity: 80 tons (customized 20–200 tons available).

Power Source: Maintenance-free battery pack or lithium battery system.

Drive Type: Dual-motor drive system with differential control.

Steering Mode: Electric steering with 360° rotation capability.

Lifting System: Integrated hydraulic platform for vertical load adjustment.

Wheel Material: Industrial-grade polyurethane or solid rubber tires (non-marking).

Operation Mode: Wireless remote control + onboard control panel.

Chassis Structure: Heavy-duty welded frame (Q345B steel) for extreme durability.

Key Advantages

Heavy-Duty Performance

Designed for large and concentrated loads up to 80 tons.

Equipped with high-torque motors for smooth acceleration and braking under full load.

Trackless Flexibility

No fixed rails required — can move freely across workshops, bays, and outdoor yards.

Capable of 360° rotation and diagonal travel, ideal for confined spaces.

Integrated Hydraulic Lift System

Provides precise height control for loading, positioning, or alignment tasks.

Hydraulic cylinder system ensures stable lifting under heavy loads.

Intelligent Control System

Operated by remote controller or onboard joystick.

Equipped with speed control, steering feedback, and position monitoring.

Optional PLC automation or laser navigation available for advanced logistics systems.

Safety & Protection Features

Emergency stop buttons, anti-collision sensors, and audible-visual alarms.

Soft start & stop system prevents cargo shift or impact.

Overload protection and hydraulic lock valve ensure lifting safety.

Typical Applications

Steel and metal processing — transporting heavy plates, coils, and fabricated structures.

Automotive and mold workshops — moving dies, molds, and tools between production lines.

Machinery manufacturing — handling large mechanical components or machine assemblies.

Shipbuilding and aerospace — transferring oversized modules or equipment.

Maintenance bays and assembly lines — lifting and aligning heavy parts.

Optional Configurations

Explosion-proof or heat-resistant design for special working conditions.

Hydraulic scissor lift table or tilt-type platform.

Automatic obstacle detection and route navigation (AGV/AMR function).

Wireless charging station or exchangeable battery pack.

Integrated turntable or synchronized multi-cart system for large-scale handling.

Custom platform deck: flat, V-shaped, or roller-type for coil or roll transport.