The 10-ton Raw Material Rail Transfer Vehicle is a high-performance electric transport vehicle designed specifically for internal logistics within factory workshops and warehouses.

Powered by batteries, it relies on fixed rails for safe and efficient material transfer between production stages.

This vehicle is primarily used for short-distance transport of large quantities of raw materials, such as steel, castings, plates, coils, profiles, hardware, and semi-finished products. It replaces traditional forklift or manual handling methods, effectively reducing labor intensity, improving production efficiency, and significantly minimizing safety risks during material handling.

The 10-ton load capacity meets the needs of centralized handling of medium-weight materials, making it an ideal choice for upgrading internal material management within modern manufacturing plants.

Core Advantages:

1️⃣ Powerful Load Capacity

With a rated load capacity of 10 tons per vehicle, it can easily handle the centralized transport of a variety of raw materials.

The vehicle structure is reinforced with welded Q235 steel, providing a stable and impact-resistant structure.

The vehicle platform can be customized with flatbed, guardrail, or roller configurations to suit different raw material transportation requirements.

2️⃣ Battery-Powered, Eco-Friendly

Equipped with high-capacity lead-acid or lithium batteries, it enables long-term continuous operation.

Batteries can be quickly replaced or recharged online, minimizing downtime.

Emission-free and low-noise operation ensures compliance with green factory standards.

3️⃣ Track-Guided, Stable Operation

Fixed track provides operational guidance, ensuring precise positioning and smooth operation.

Supports straight, curved, and crisscross track designs to accommodate diverse workshop layouts.

Automated diversion tracks can be designed for special scenarios, improving workshop logistics efficiency.

4️⃣ Multiple Safety Features

Audio-visual alarm system: Automatically alerts during operation to ensure the safety of nearby personnel.

Emergency stop switch: Immediately stops the equipment in an emergency.

Limited position protection device: Prevents overrunning or collisions.

Optional laser scanning or infrared sensing systems provide advanced automatic collision avoidance.

Supports zone speed limits, cushioned start, and cushioned braking for enhanced transport safety.

5️⃣ Intelligent Control, Easy Operation

Dual control modes: handle operation + wireless remote control, flexible response to different working conditions;

Supports stepless speed adjustment, allowing the operating speed to be freely set according to actual needs;

The expandable automated control system enables unmanned or automatic dispatching.

Technical Specifications

This rail transfer vehicle has a rated load capacity of 10 tons, making it ideal for centralized transportation of medium-sized raw materials or finished products.

The battery system can be configured with either 48V or 72V voltage, with different capacities tailored to the customer's actual operation time and transport distance. The battery life typically reaches 6-8 hours, with a charging time of approximately 4-6 hours.

The operating speed is adjustable from 0-20 m/min, adapting to different production cycles and operating scenarios, ensuring efficient and smooth transportation.

The track section typically utilizes P38, P43, or P50 rails, and can be designed and reinforced to suit the actual load and operating environment. It supports straight, curved, and intersecting track layouts. The equipment comes standard with an audible and visual alarm, an emergency stop, a buffer and collision avoidance function, and limit switches. Optional laser collision avoidance and automatic navigation modules are available upon request, enabling more intelligent factory logistics management.

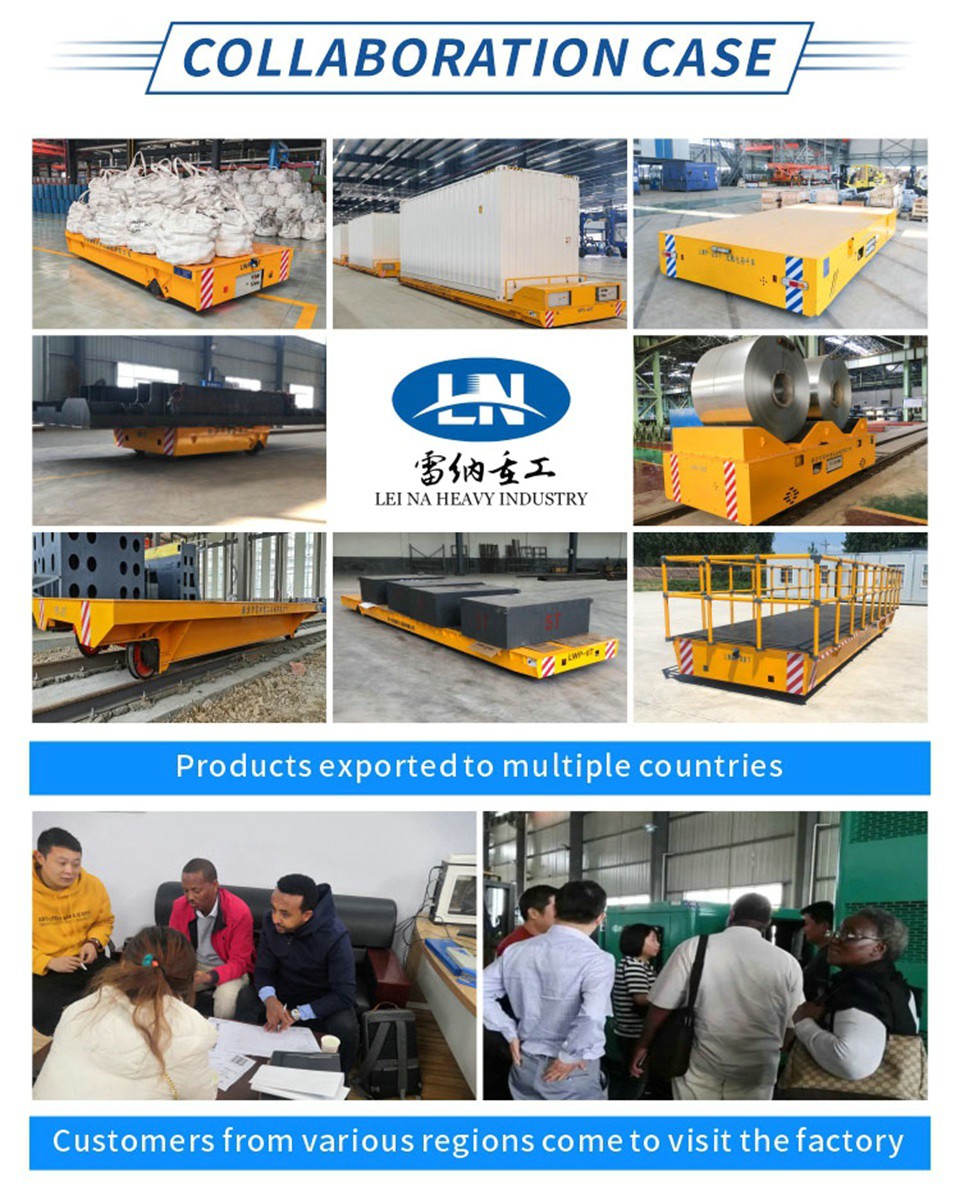

Typical Application Scenarios

1. Raw Material Loading and Transportation

Transporting bulk raw materials such as steel, coils, and castings from storage to the production line, reducing manual handling and lowering labor intensity.

2. Intra-factory Logistics

Transporting semi-finished products or processed parts between workshops, ensuring efficient connection between production links.

3. Finished Product Off-Line Transportation

Transporting finished products or large fixtures from the production workshop to the finished product warehouse, ensuring safe and stable transportation.

4. Hazardous Area Operations

Suitable for high-temperature, high-risk, or toxic workshops, such as those in the metallurgical and chemical industries, where remote control reduces exposure risks.

Customized Services

To ensure the equipment best suits customer needs, we provide comprehensive customized services, including:

Track Planning and Construction: Track design and installation services tailored to workshop layout.

Carriage Structure Design: Options include flatbed, guardrail, roller conveyor, or lift platform.

Battery Options: Supports lead-acid and lithium batteries, with the optimal option selected based on operating frequency.

Automation Expansion: Seamlessly integrates with AGV or MES systems to achieve intelligent logistics.

Safety Upgrades: Optional laser collision avoidance, zone speed limit, and remote monitoring modules.

Product Advantages

The 10-ton Rail-Mounted Raw Material Transfer Vehicle, with its core advantages of high load capacity, stability, safety, and intelligence, can comprehensively upgrade enterprises' internal logistics and transportation.

Higher Load Capacity: Meets the needs of centralized raw material transportation;

Safer and More Reliable: Comprehensive safety protection design reduces transportation risks;

More Environmentally Friendly: Battery-powered, low noise, and zero emissions;

Smarter and More Efficient: Seamlessly integrates with production lines and intelligent scheduling systems;

More Customizable: Structure, functions, and battery options are all customizable.